A spiral bed biofilm reactor for sewage treatment

A biofilm reactor and sewage treatment technology, applied in the fields of environmental engineering and chemical engineering, can solve the problems of uneven distribution, local carrier accumulation and insufficient liquid mixing, so as to ensure the circulation rate and facilitate the gas-liquid mass transfer rate , The effect of reducing the loss of vertical pressure head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: spiral bed biofilm reactor

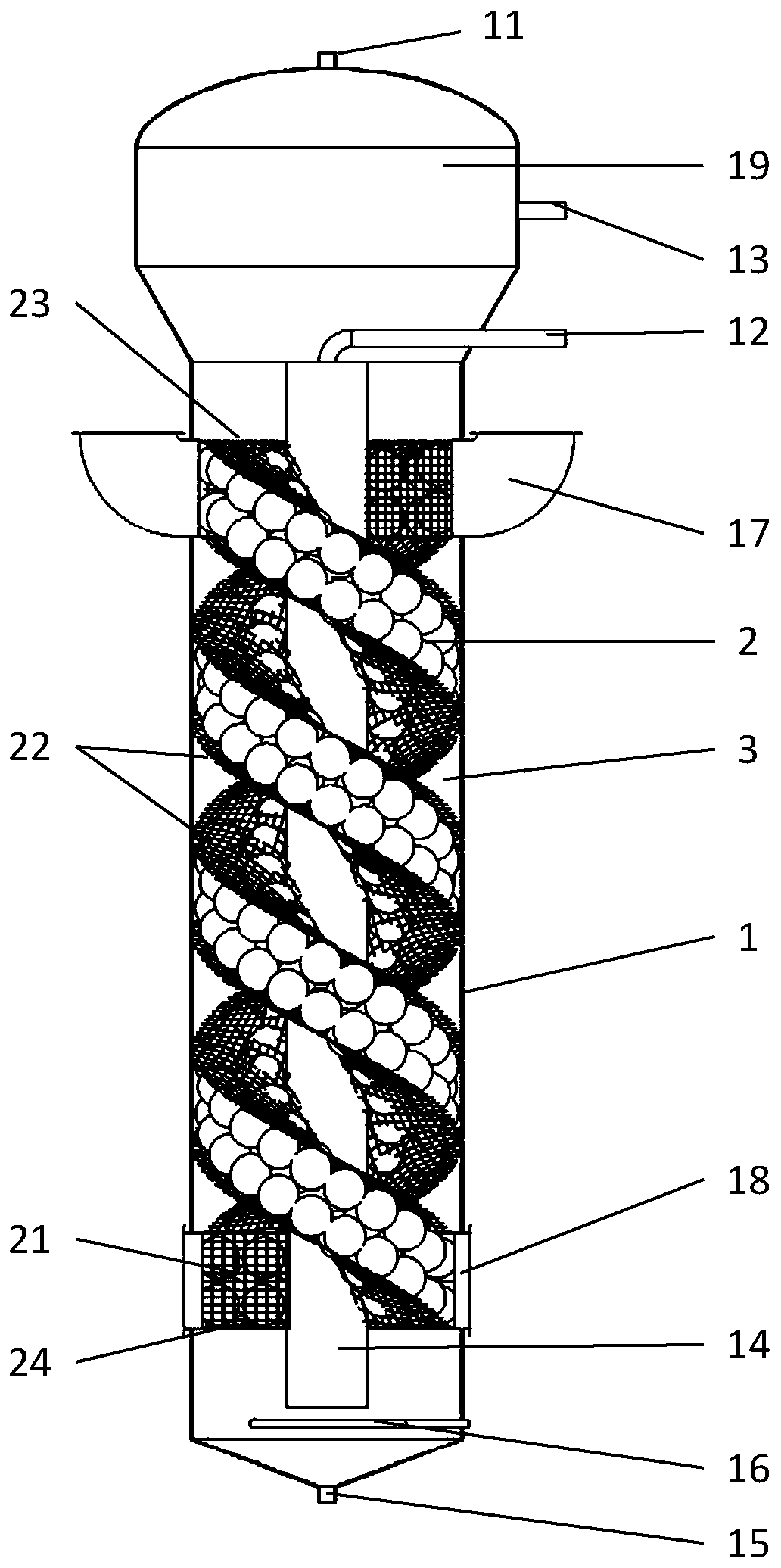

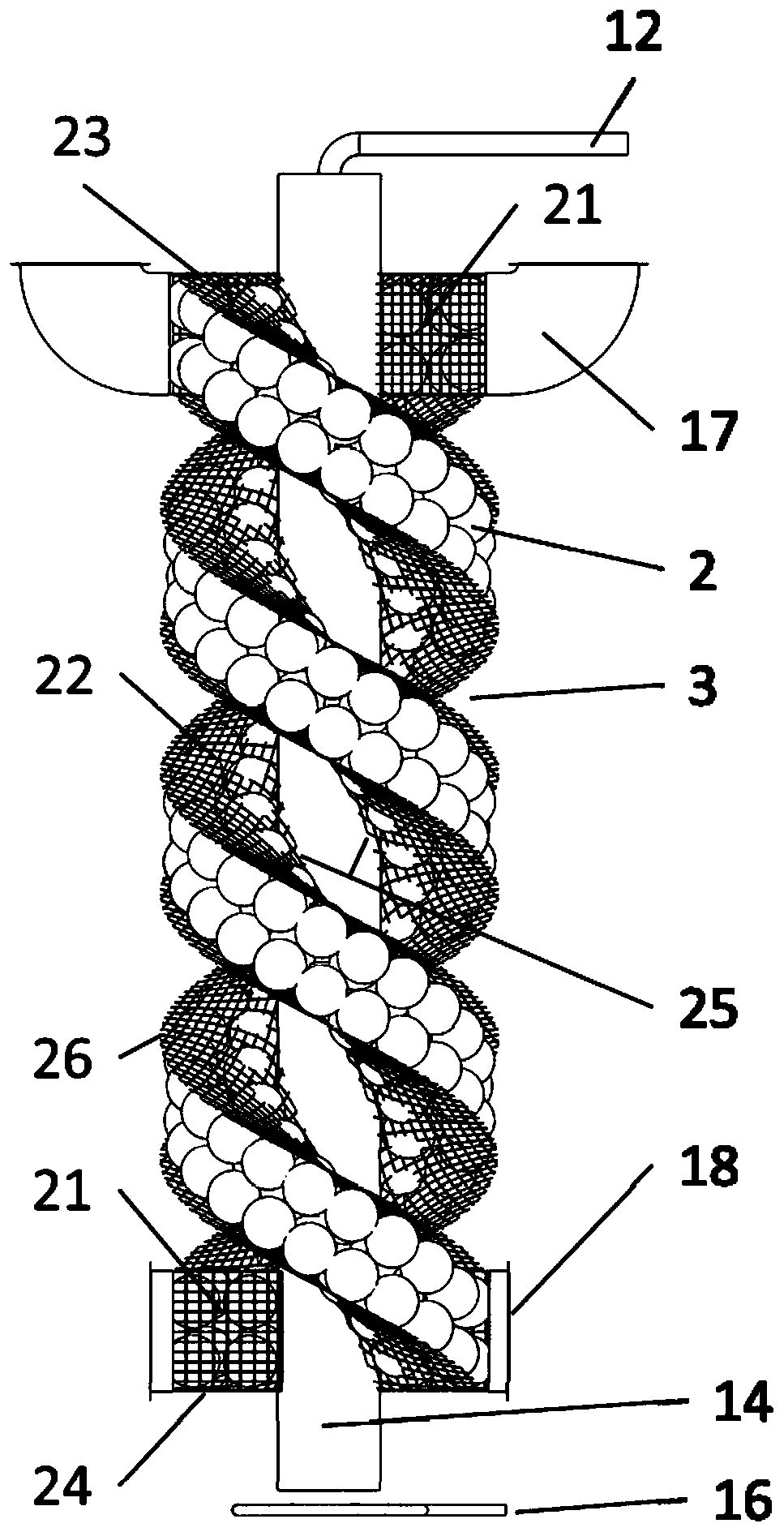

[0054] like Figure 1~5 As shown, a spiral bed biofilm reactor for sewage treatment includes a reaction tank 1, a draft tube 14, an empty channel 3 and a carrier channel 2; the inner space of the tank 1 includes a gas-liquid mixing zone and is located in the gas The gas-liquid separation zone 19 above the liquid mixing zone; the gas-liquid separation zone 19 refers to the area above the liquid level in the reactor, including the area where the foam is located; the gas-liquid mixing zone is the area below the liquid level; the tank body 1 The top of the tank is provided with an exhaust port 11, the bottom is provided with a mud discharge port 15, and a water outlet 13 and a water inlet 12 are arranged on the side wall of the tank body 1; the water inlet 12 is located near the top of the draft tube, and the water outlet 13 is located at the water inlet 12 above; the guide tube 14 is coaxially arranged with the tank body 1, and t...

Embodiment 2

[0076] Example 2: 200L spiral bed biofilm reactor

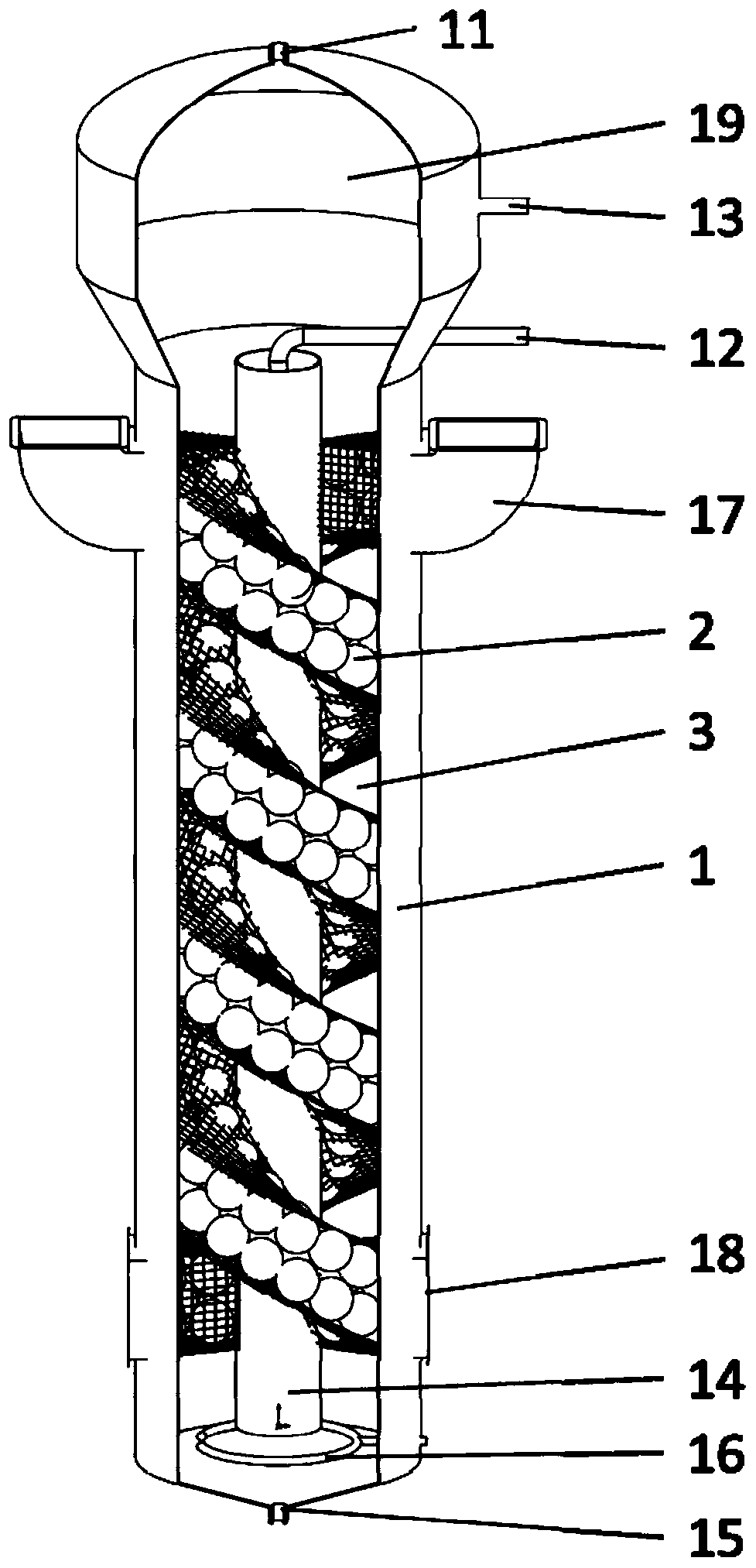

[0077] Such as Figure 4~6 As shown, a spiral bed biofilm reactor filled with a carrier, the basic structure is similar to that of Example 1, the difference is that the inner diameter of the reaction tank corresponding to the gas-liquid separation zone 19 is the same as that of the reaction tank corresponding to the gas-liquid mixing zone The inner diameter of the body is the same.

[0078] The inner diameter of the reaction tank 1 is 370 mm, the cylinder height is 2260 mm, the lower part is an elliptical steel head, and the upper part is open. The outer diameter of the diversion cylinder 14 is 160mm, the height is 1500mm, and the thickness is 5mm. The bottom of the diversion cylinder 14 is 80mm from the lower edge of the cylinder of the reaction tank, and is supported on the bottom of the reaction tank by 3 legs. Body 10 is installed coaxially. Sewage is directly passed into the upper part of the guide tube 14 through the...

Embodiment 3

[0086] Embodiment 3: Aerobic aeration effect of spiral bed biofilm reactor

[0087] Taking the spiral bed biofilm reactor described in Example 2 as the implementation device, the aerobic biological treatment performance test of sewage was carried out, and compared with the activated sludge method.

[0088] The inoculum sludge comes from the secondary sedimentation tank of a municipal sewage treatment plant in Jiangsu. The concentration of the initial inoculum sludge in the reactor is 5800 mg / L mixed liquid suspended solids (MLSS). The feed liquid is synthetic sewage, composed of: glucose (500mg / L), NH 4 Cl (270mg / L), KH 2 PO 4 (44mg / L), MgSO 4 ·5H 2 O (20mg / L), CaCl 2 (10mg / L), FeSO 4 (2.5mg / L), CuSO 4 ·5H 2 O (0.39mg / L), MnCl 2 4H 2 O (0.28mg / L), prepared from tap water, pH 6.8-7.0.

[0089] Taking the airlift reactor as a comparison, there is no spiral screen and carrier in the airlift reactor, and the size of the reaction vessel is the same as that of the spiral ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com