A composite material for efficiently controlling bottom mud phosphorus release and a preparing method thereof

A composite material and phosphorus release technology, applied in chemical instruments and methods, sludge treatment, other chemical processes, etc., can solve the problems of not very ideal inhibition and removal effect, affecting ORP of water body, etc., to prolong effective action time and efficient control Phosphorus released from sediment, effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The composition will be 58% (mass) CaSO 4 , 2% (mass) AlCl 3 , 20% (mass) CaCO 3 , 20% (mass) The mixture of quartz sand with a particle size of 1mm is uniformly mixed with sodium lauryl sulfate and water, wherein the mass ratio of the mixture to water is 1: 0.8~1.2, and the mass fraction of foaming agent to water is 0.1%, standing still, fully solidified and shaped, then dried to obtain a composite material A that controls the release of phosphorus from the sediment.

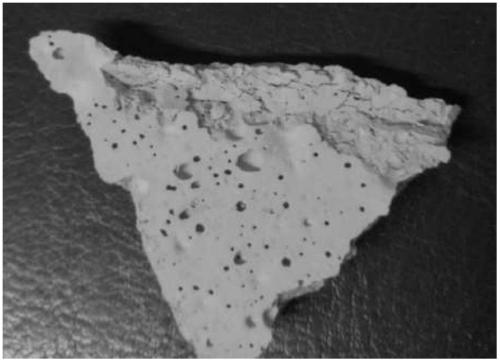

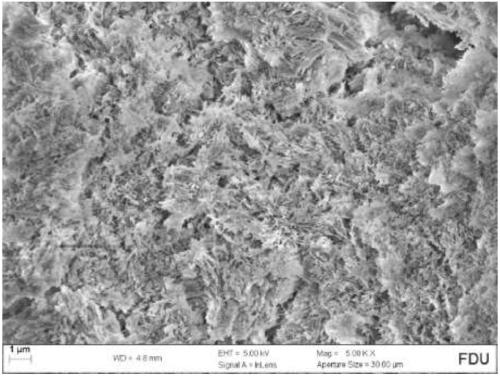

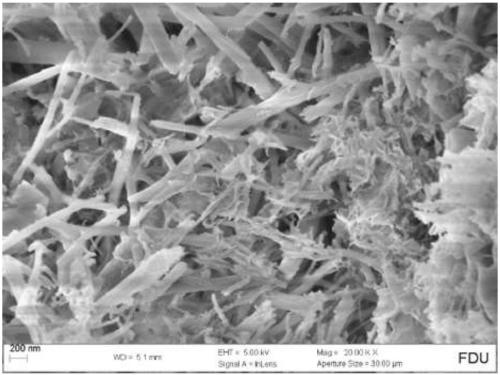

[0021] The surface morphology of A is as Figure 1 to Figure 3 shown. From figure 1 It can be seen from the figure that there are pores distributed on the surface of composite material A; from figure 2 and image 3 It can be seen from the figure that the surface of the composite material A has a dense network structure, and the dense network structure is formed by the intersecting of countless dendrite-like crystals. Irregular pores with a diameter of 100-300nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com