High-flowability antibacterial polypropylene compound material and preparation method of same

A technology of antibacterial polypropylene and composite materials, applied in the field of high fluidity antibacterial polypropylene composite materials and its preparation, can solve the problem of affecting the melt fluidity of polypropylene composite materials, reducing the melt fluidity of polypropylene composite materials, polypropylene composite materials Influence of strength and other issues, to achieve the effect of improving melt fluidity, easy processing and molding, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

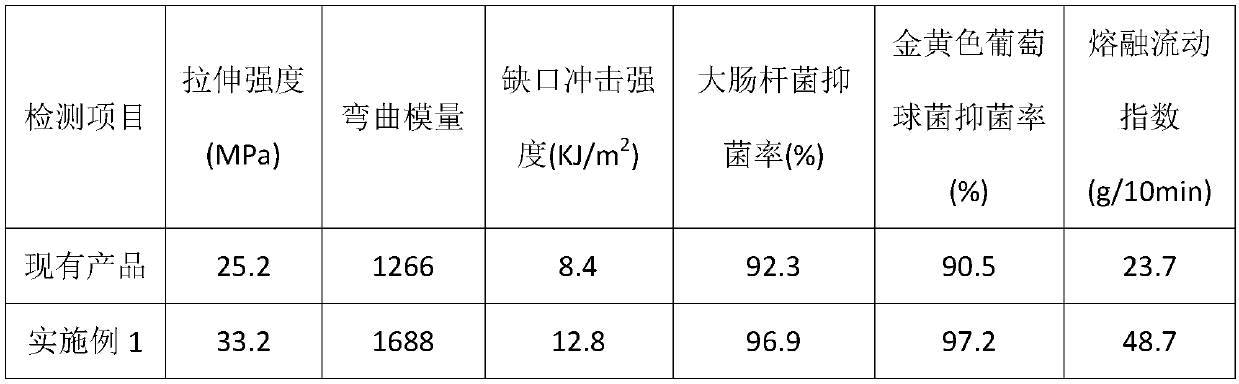

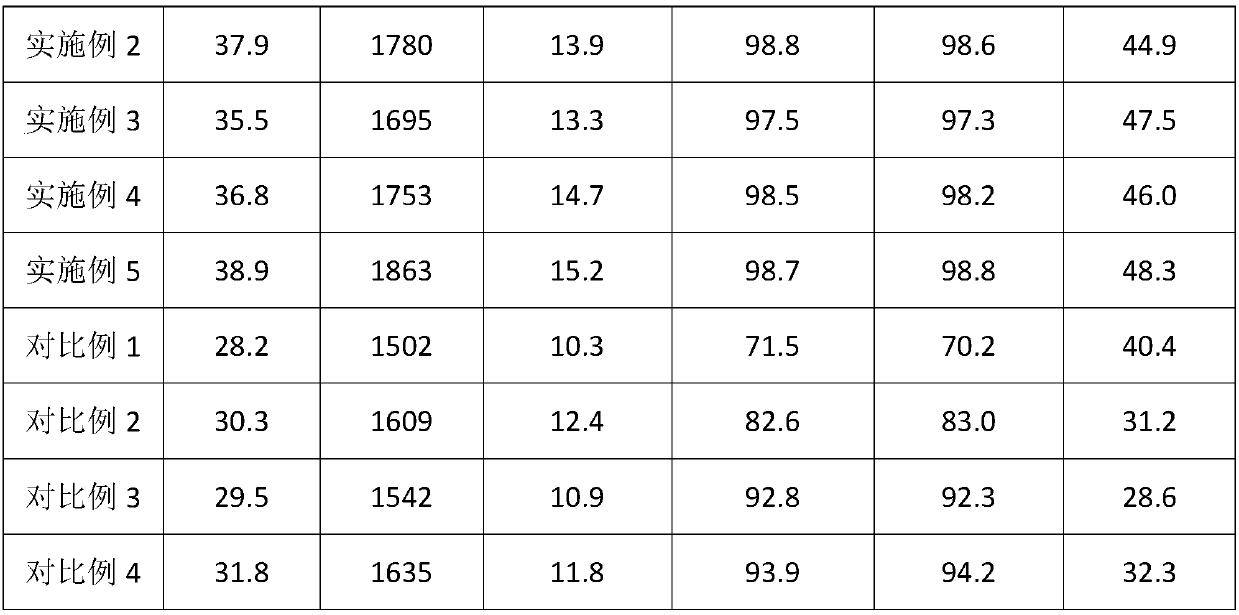

Examples

Embodiment 1

[0026] A high fluidity antibacterial polypropylene composite material, with polypropylene resin as the matrix, including the following components in parts by weight: 85 parts of polypropylene resin, 5 parts of thermoplastic vulcanizate, 2 parts of modified copper oxide nanorods, boric acid 5 parts of magnesium whiskers, 2 parts of modified polytetrafluoroethylene micropowder, and 0.1 part of coupling agent; wherein, the modified copper oxide nanorods are copper oxide nanorods modified by organosilicon quaternary ammonium salts, and the modified polytetrafluoroethylene The micropowder is obtained by coating nano silicon dioxide on the surface of polytetrafluoroethylene micropowder by electrostatic adsorption technology, and the coupling agent is a polyether modified silane coupling agent.

[0027] The preparation method of the above-mentioned high fluidity antibacterial polypropylene composite material specifically comprises the following steps:

[0028] (1) Preparation of modi...

Embodiment 2

[0034] A high-fluidity antibacterial polypropylene composite material, using polypropylene resin as a matrix, including the following components in parts by weight: 55 parts of polypropylene resin, 15 parts of thermoplastic vulcanizate, 8 parts of modified copper oxide nanorods, boric acid 12 parts of magnesium whiskers, 9 parts of modified polytetrafluoroethylene powder, and 1 part of coupling agent; wherein, the modified copper oxide nanorods are copper oxide nanorods modified by organosilicon quaternary ammonium salts, and the modified polytetrafluoroethylene The micropowder is obtained by coating nano silicon dioxide on the surface of polytetrafluoroethylene micropowder by electrostatic adsorption technology, and the coupling agent is a polyether modified silane coupling agent.

[0035] The preparation method of the above-mentioned high fluidity antibacterial polypropylene composite material specifically comprises the following steps:

[0036] (1) Preparation of modified c...

Embodiment 3

[0042]A high-fluidity antibacterial polypropylene composite material, with polypropylene resin as the matrix, including the following components in parts by weight: 80 parts of polypropylene resin, 7 parts of thermoplastic vulcanizate, 4 parts of modified copper oxide nanorods, boric acid 8 parts of magnesium whiskers, 4 parts of modified polytetrafluoroethylene powder, and 0.3 parts of coupling agent; wherein, the modified copper oxide nanorods are copper oxide nanorods modified by organic silicon quaternary ammonium salt, and the modified polytetrafluoroethylene The micropowder is obtained by coating nano silicon dioxide on the surface of polytetrafluoroethylene micropowder by electrostatic adsorption technology, and the coupling agent is a polyether modified silane coupling agent.

[0043] The preparation method of the above-mentioned high fluidity antibacterial polypropylene composite material specifically comprises the following steps:

[0044] (1) Preparation of modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com