Composition for preparing vapor barrier and preparation method of composition

A composition and vapor barrier technology, which is applied in the field of vapor barrier preparation, can solve the problems of insufficient bonding performance and frost resistance of vapor barrier materials, achieve excellent frost resistance, less air bubble content, and improve the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

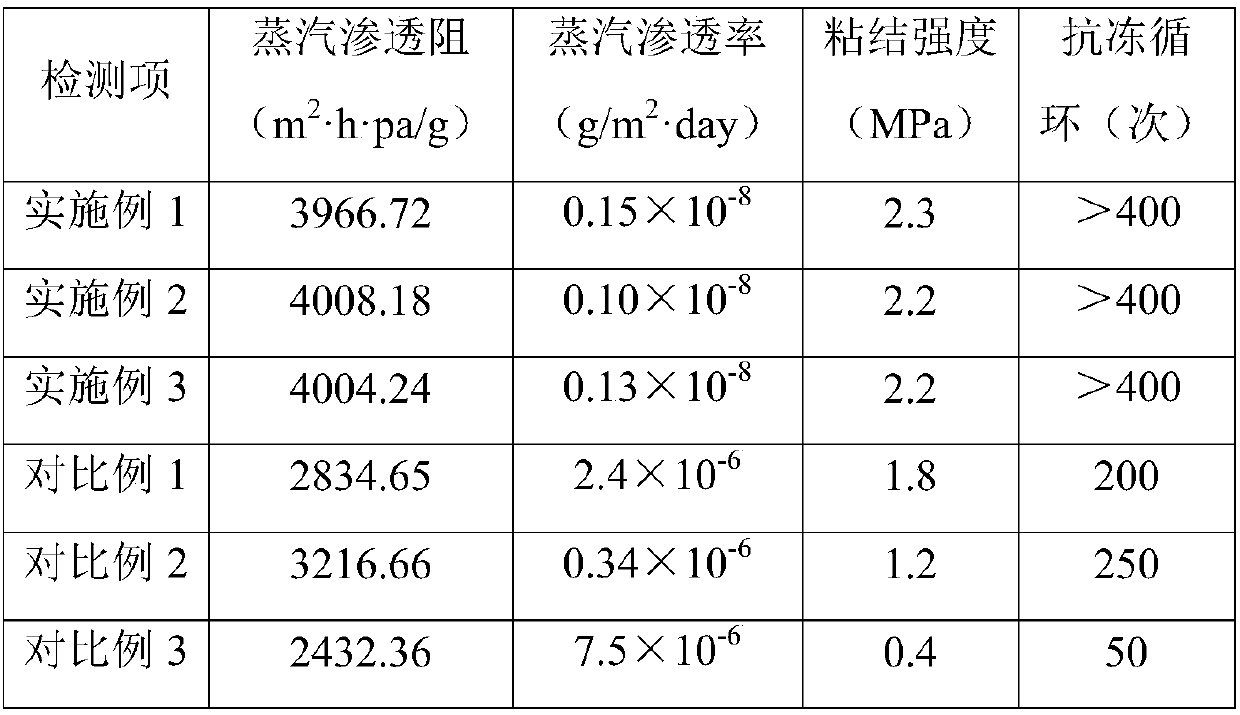

Examples

Embodiment 1

[0031] A composition for preparing a vapor barrier, comprising the following components in parts by weight:

[0032] 50 parts of polyurethane, 40 parts of modified epoxy resin, 10 parts of flame retardant, 5 parts of silane coupling agent KH550 and 20 parts of admixture.

[0033] Wherein, the admixture comprises the following components by weight:

[0034] 20 parts of cement, 15 parts of quartz sand, 10 parts of phenolic resin, 10 parts of sodium citrate and 15 parts of glass fiber;

[0035] Flame retardant comprises the following components by weight:

[0036] 15 parts of sodium silicate, 10 parts of aluminum hydroxide and 10 parts of sodium metaborate.

[0037] The above-mentioned preparation method for preparing the composition of vapor barrier layer, comprises the following steps:

[0038] (1) mixing polyurethane and modified epoxy resin according to the formula, and pulverizing into organic particles with a particle size of 600 mesh;

[0039] (2) mixing the flame reta...

Embodiment 2

[0042] A composition for preparing a vapor barrier, comprising the following components in parts by weight:

[0043] 80 parts of polyurethane, 60 parts of modified epoxy resin, 15 parts of flame retardant, 5 parts of silane coupling agent KH792 and 25 parts of admixture.

[0044] Wherein, the admixture comprises the following components by weight:

[0045] 25 parts of cement, 18 parts of quartz sand, 15 parts of phenolic resin, 10 parts of sodium citrate and 20 parts of glass fiber;

[0046] Flame retardant comprises the following components by weight:

[0047] 15 parts of sodium silicate, 10 parts of aluminum hydroxide and 10 parts of sodium metaborate.

[0048] The above-mentioned preparation method for preparing the composition of vapor barrier layer, comprises the following steps:

[0049] (1) mixing polyurethane and modified epoxy resin according to the formula, and pulverizing into organic particles with a particle diameter of 800 mesh;

[0050] (2) mixing the flame ...

Embodiment 3

[0053] A composition for preparing a vapor barrier, comprising the following components in parts by weight:

[0054] 80 parts of polyurethane, 60 parts of modified epoxy resin, 20 parts of flame retardant, 10 parts of silane coupling agent KH560 and 30 parts of admixture.

[0055] Wherein, the admixture comprises the following components by weight:

[0056] 30 parts of cement, 20 parts of quartz sand, 15 parts of phenolic resin, 15 parts of sodium citrate and 20 parts of glass fiber;

[0057] Flame retardant comprises the following components by weight:

[0058] 20 parts of sodium silicate, 10 parts of aluminum hydroxide and 15 parts of sodium metaborate.

[0059] The above-mentioned preparation method for preparing the composition of vapor barrier layer, comprises the following steps:

[0060] (1) mixing polyurethane and modified epoxy resin according to the formula, and pulverizing into organic particles with a particle size of 600 mesh;

[0061] (2) mixing the flame ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com