Environment-friendly clay stabilizer

A clay stabilizer and environment-friendly technology, applied in the field of downhole operations in oil and gas field exploration and development, can solve problems such as high biological toxicity, carcinogenic effects, and impact on the ecological environment, and achieve high temperature resistance, high anti-swelling performance, and excellent environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

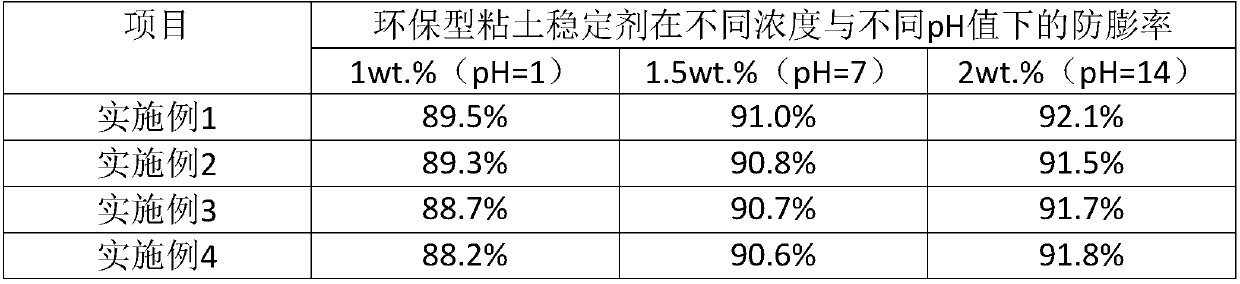

Examples

Embodiment 1

[0030] An environmentally friendly clay stabilizer, the specific preparation steps are as follows:

[0031] S1. Dissolve 100g of N-aminoethylethanolamine in 240mL of water; while stirring, heat up to 30°C, add 170g, 37wt.% formaldehyde aqueous solution dropwise, after the dropwise addition, heat up to 80°C, and then add 140g chlorine dropwise Benzyl benzyl chloride, keep at 80°C and continue to react for 3 hours after the dropwise addition is completed to obtain benzyl quaternary ammonium salt;

[0032] S2. Dissolve 110g of N-aminoethylethanolamine in 300mL of water; under stirring, heat up to 40°C, add 180g, 37wt.% formaldehyde aqueous solution dropwise for 30min, after the addition, warm up to 80°C, then dropwise Add 80g of dichloroethyl ether, which lasts for 10 minutes, after the addition, the temperature is raised to 90°C, and the reaction is continued for 16 hours to obtain the heterocyclic polyquaternary ammonium salt;

[0033] S3. Dissolve 165g of diethanolamine in 210mL of ...

Embodiment 2

[0036] S1. Dissolve 140g of N-aminoethylethanolamine in 280mL of water; while stirring, keep the temperature at 45°C, add 190g, 37wt.% formaldehyde aqueous solution dropwise, after the dropwise addition, heat to 90°C, and then add 150g chlorine dropwise Benzyl benzyl ammonium salt is maintained at 90°C for 4 hours after the dropwise addition is completed to obtain benzyl quaternary ammonium salt;

[0037] S2. Mix 130 g of N-aminoethylethanolamine and 320 mL of water, and maintain the temperature at 55°C under stirring. Add 190g of 37wt.% formaldehyde aqueous solution dropwise. After 30 minutes of dropping, the temperature is raised to 90°C, and then 90g of dichloroethyl ether is added dropwise for 10 minutes. After the dropping, the temperature is raised to 110°C, and the reaction is continued for 20 hours to obtain a heterocyclic polyquaternium. Ammonium salt

[0038] S3. Dissolve 175g of diethanolamine in 230mL of water; while stirring, heat up to 55°C, add 70g, 37wt.% formaldeh...

Embodiment 3

[0041] S1. Dissolve 120g of N-aminoethylethanolamine in 260mL of water; while stirring, heat up to 40°C, add 180g, 37wt.% formaldehyde aqueous solution dropwise, after the dropwise addition, heat up to 85°C, and then add 145g chlorine dropwise Benzyl benzyl chloride, keep at 85°C and continue to react for 3.5 hours after the dropwise addition is completed to obtain benzyl quaternary ammonium salt;

[0042] S2. Combine 120g of N-aminoethylethanolamine and 310mL of water; under stirring conditions, heat up to 50°C, add 185g of 37wt.% formaldehyde aqueous solution dropwise for 30 minutes, after the addition, heat up to 85°C, and then add 85g of water dropwise. Chloroethyl ether, which lasted 10 minutes, heated to 100°C after dripping, and continued to react for 18 hours to obtain heterocyclic polyquaternary ammonium salt;

[0043] S3. Dissolve 170g of diethanolamine in 220mL of water; while stirring, heat to 50°C, add 65g, 37wt.% formaldehyde aqueous solution dropwise for 25min, after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lc50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com