Screening method of flavonoid substances in camellia nitidissima to nasopharyngeal darcinoma acted effective bits

A screening method and technology for camellia tea, which are applied in the fields of compound screening, drug screening, biochemical equipment and methods, etc., can solve the problems of difficult to determine tumor-inhibiting active ingredients, complex ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

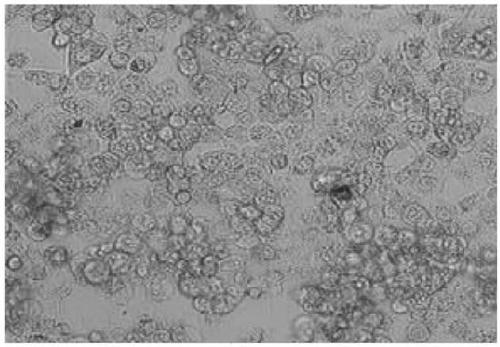

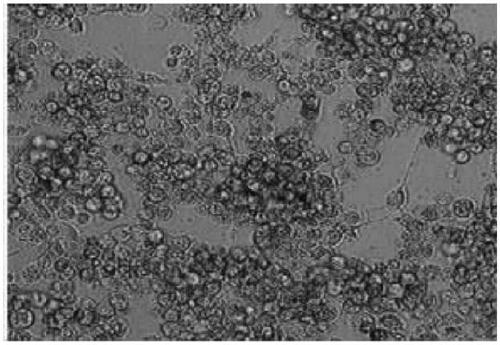

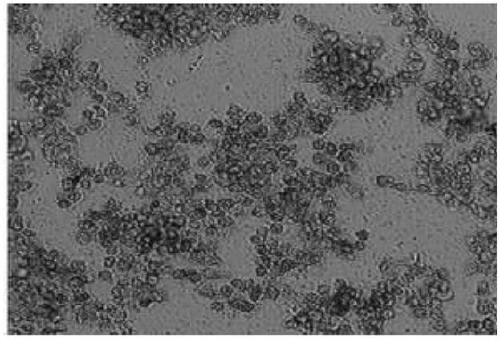

Image

Examples

Embodiment 1

[0035] Preparation of golden camellia tea concentrate: pick the fresh golden camellia leaves in spring, after screening, washing, crushing and other processes, 1.0 kg of the crushed golden camellia original leaves; add 1.8L of ethanol (more than 95%), and use Extract with an extractor for 5-6 hours to obtain extract A; add about 1.5 L of acetone (above 95%) to the residue after extraction, and sonicate at 40-60°C for about 1.5 hours to obtain extract B, and combine extracts A and B, The acetone and ethanol solvents were removed by rotary evaporation with a rotary evaporator to obtain about 0.26 L of Camellia camellia concentrate in the organic phase.

[0036] Preparation process of ferroferromagnetic particle-PAMAM composite material: under nitrogen protection, at pH 1.7, a mixture of ferric chloride solution (0.085mol / L) and ferrous sulfate (0.05mol / L) was prepared. Then, a 1.5 mol / L ammonia solution was added dropwise to the mixture, and vigorously stirred until pH=9. The f...

Embodiment 2

[0050] Preparation of camellia camellia flower concentrate: picking fresh golden camellia flowers in autumn, screening, washing, crushing and other processes, 0.9 kg of crushed camellia camellia flowers; adding 1.9L of ethanol (more than 95%), using a Soxhlet extractor Extract for 5-6 hours to obtain extract A; add about 1.3L of acetone (above 95%) to the residue after extraction, and sonicate for about 1.5 hours at 40-60°C to obtain extract B, combine extracts A and B, and use a rotating The acetone or ethanol solvent was removed by rotary evaporation with an evaporator to obtain about 0.25 L of Camellia camellia flower concentrate in the organic phase.

[0051]Preparation process of ferroferromagnetic particle-PAMAM composite material: under nitrogen protection, at pH 1.7, a mixture of ferric chloride solution (0.085mol / L) and ferrous sulfate (0.05mol / L) was prepared. Then, a 1.5 mol / L ammonia solution was added dropwise to the mixture, and vigorously stirred until pH=9. Th...

Embodiment 3

[0068] Preparation of camellia japonica fruit concentrate: picking chrysanthemum camellia fruit in December, screening, washing, crushing, vacuum drying and other processes, 1.1 kg of camellia japonica fruit after crushing; adding 1.9L of ethanol (more than 95%), using the Extracted with the extractor for 5-6 hours to obtain extract A; add 1.7L acetone (above 95%) to the residue after extraction, and ultrasonicate for about 1.5h at 40-60°C to obtain extract B, and combine extracts A and B, The acetone and ethanol solvents were removed by rotary evaporation with a rotary evaporator to obtain about 0.3 L of Camellia camellia fruit concentrate in the organic phase.

[0069] Preparation process of ferroferromagnetic particle-PAMAM composite material: under nitrogen protection, at pH 1.7, a mixture of ferric chloride solution (0.085mol / L) and ferrous sulfate (0.05mol / L) was prepared. Then, a 1.5 mol / L ammonia solution was added dropwise to the mixture, and vigorously stirred until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com