High-strength flashover preventing aluminum alloy for electric power fittings and preparation method of high-strength flashover preventing aluminum alloy

A technology for power fittings and aluminum alloys is applied in the field of high-strength anti-flashover aluminum alloys for power fittings and their preparation, which can solve the problems of poor comprehensive strength and hardness and insufficient strength, and achieve good transition, high uniformity, and comprehensive stability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

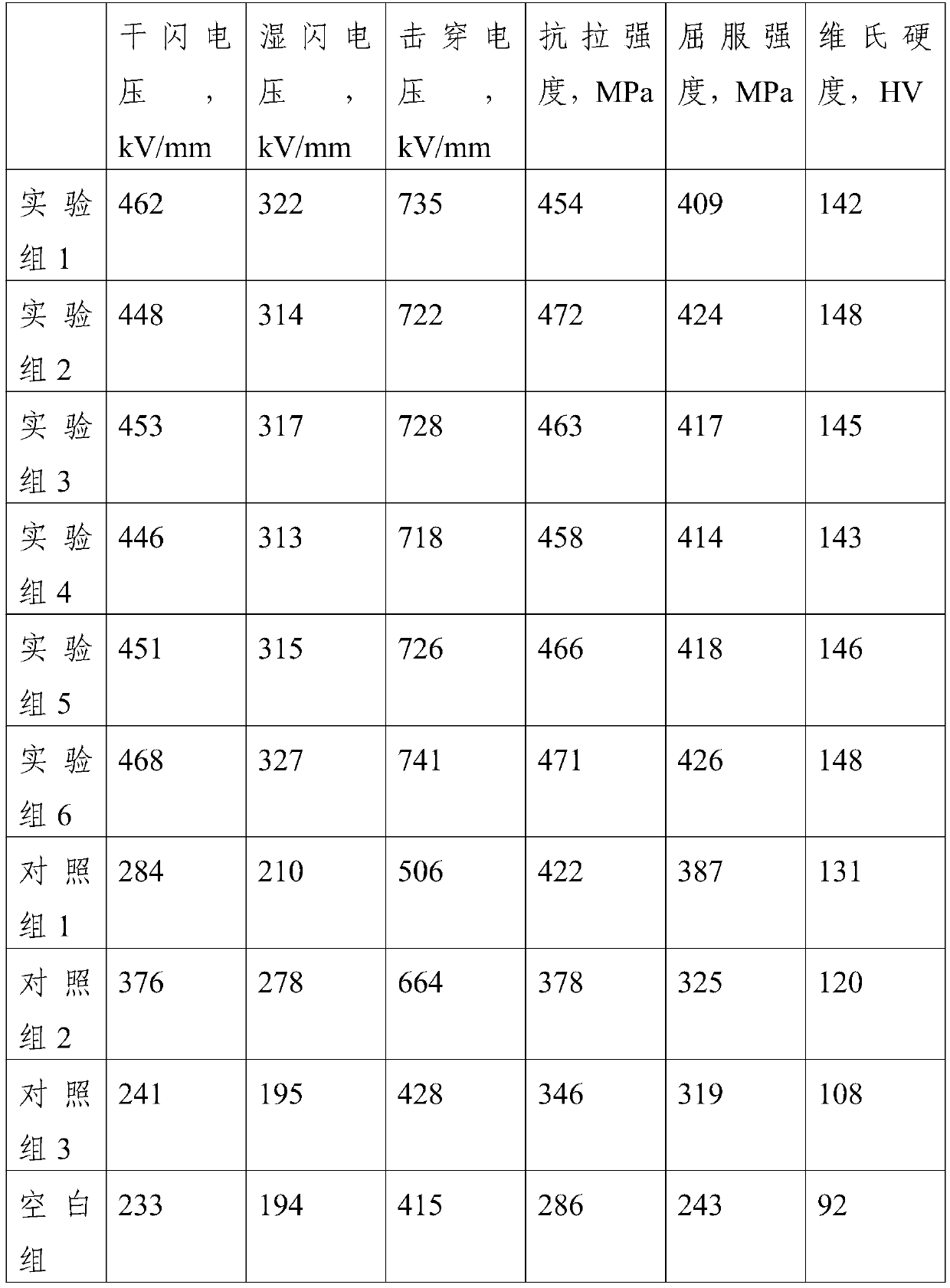

Examples

Embodiment 1

[0027] A high-strength anti-flashover aluminum alloy for electric fittings, comprising the following parts by weight: 60 parts of aluminum alloy ingot, 6 parts of nano-titanium dioxide powder, 3 parts of sepiolite fiber, 2.5 parts of acetylene carbon black, and 3 parts of nitride micropowder; It also includes 1 part of chrome ore, 2 parts of active zinc oxide, 1.5 parts of rare earth oxide and 0.12 part of foaming agent.

[0028] in:

[0029] Aluminum alloy ingots include the following elements in mass percentage: Mg 1.35-1.6%, Fe0.2-0.4%, Cu2.5-3.8%, B 0.03-0.08%, V 0.05-0.12%, Mn 0.03-0.05%, Cr 0.05-0.2%, Ge 0.3-0.4%, RE 0.01-0.15%, the balance is Al and unavoidable impurities. RE is a composition of Ce, Sc, Sm, and Y, and the mass of Ce+Sc accounts for more than 60% of the total mass of RE.

[0030] Nitride fine powder includes boron nitride, silicon nitride, and magnesium nitride, and the mass ratio of the three is 0.5:3:2.

[0031] Rare earth oxides are selected from a...

Embodiment 2

[0042] A high-strength anti-flashover aluminum alloy for electric power fittings, comprising the following parts by weight: 70 parts of aluminum alloy ingot, 6 parts of nano-titanium dioxide powder, 4 parts of sepiolite fiber, 3 parts of acetylene carbon black, and 3 parts of nitride micropowder; It also includes 2 parts of chrome ore, 3 parts of active zinc oxide, 1 part of rare earth oxide and 0.2 part of foaming agent.

[0043] in:

[0044] Aluminum alloy ingots include the following mass percentage elements: Mg 1.35-1.6%, Fe 0.2-0.4%, Cu2.5-3.8%, B 0.03-0.08%, V 0.05-0.12%, Mn 0.03-0.05%, Cr 0.05-0.2%, Ge 0.3-0.4%, RE 0.01-0.15%, the balance is Al and unavoidable impurities. RE is a composition of Ce, Sc, Sm, and Y, and the mass of Ce+Sc accounts for more than 60% of the total mass of RE.

[0045] Nitride fine powder includes boron nitride, silicon nitride, and magnesium nitride, and the mass ratio of the three is 1:4:2.

[0046] The rare earth oxide is selected from an...

Embodiment 3

[0057] A high-strength anti-flashover aluminum alloy for electric power fittings, comprising the following parts by weight: 70 parts of aluminum alloy ingot, 4 parts of nano-titanium dioxide powder, 3 parts of sepiolite fiber, 2.5 parts of acetylene carbon black, and 1 part of nitride micropowder; It also includes 1 part of chrome ore, 1 part of active zinc oxide, 2.5 parts of rare earth oxide and 0.1 part of foaming agent.

[0058] in:

[0059] Aluminum alloy ingots include the following mass percentage elements: Mg 1.35-1.6%, Fe 0.2-0.4%, Cu2.5-3.8%, B 0.03-0.08%, V 0.05-0.12%, Mn 0.03-0.05%, Cr 0.05-0.2%, Ge 0.3-0.4%, RE 0.01-0.15%, the balance is Al and unavoidable impurities. RE is a composition of Ce, Sc, Sm, and Y, and the mass of Ce+Sc accounts for more than 60% of the total mass of RE.

[0060] Nitride fine powder includes boron nitride, silicon nitride, and magnesium nitride, and the mass ratio of the three is 0.5:3:1.

[0061] The rare earth oxide is selected fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com