A kind of pretreatment method of conductive cotton fiber, conductive cotton fiber and preparation method thereof

A cotton fiber, conductive cotton technology, applied in the field of metallized functional textiles, can solve problems such as fiber damage, environmental pollution, and fiber performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

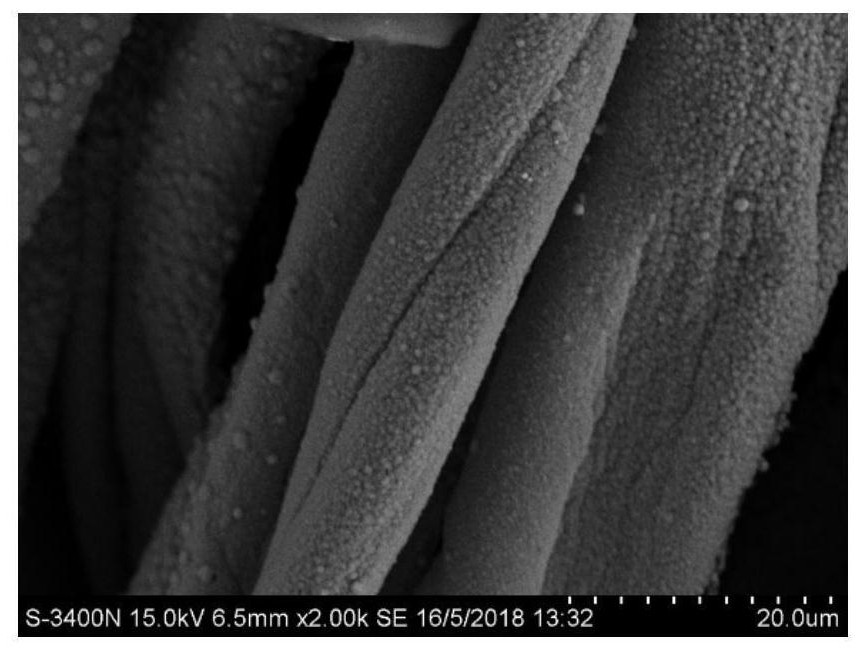

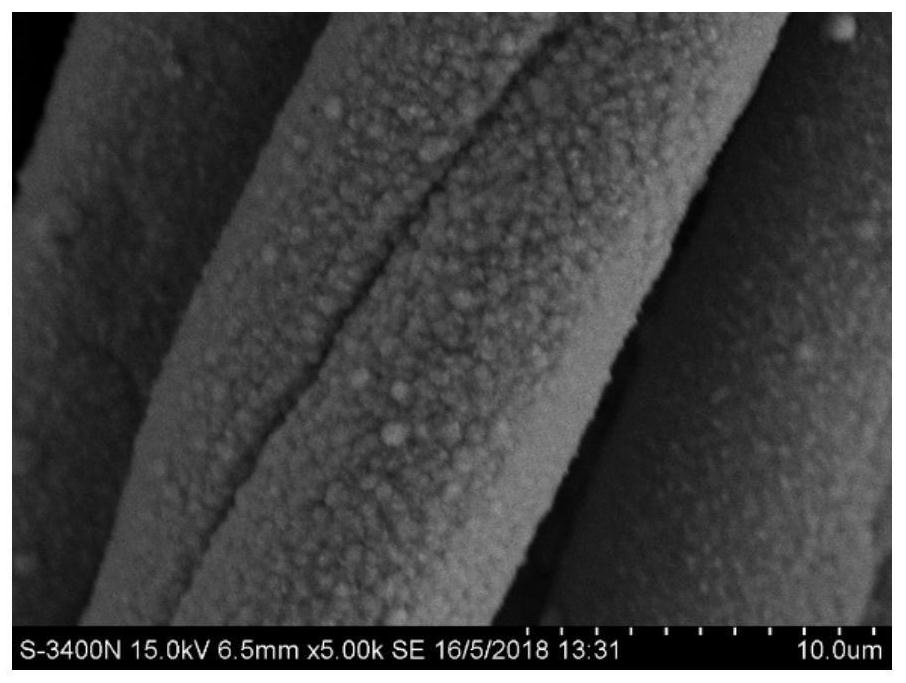

[0051] (1) Microwave-assisted treatment of cotton gauze with 2 g / L tannic acid solution for 3 minutes, taking it out, washing with deionized water three times, and drying to obtain tannic acid-modified cotton gauze.

[0052] (2) Soak the tannic acid-modified cotton gauze in 20 g / L nickel sulfate hexahydrate solution for 20 min, take it out, and obtain the modified cotton gauze with metal nickel ions adsorbed on the surface.

[0053] (4) The modified cotton gauze adsorbed with metallic nickel ions was treated with 0.02 mol / L potassium borohydride solution for 240 s, and the activated layer of metallic nickel nanoparticles was obtained by in-situ reduction.

[0054] (4) Dissolve 20g of nickel sulfate hexahydrate, 20g of sodium dihydrogen phosphate, 20g of sodium citrate, and 60g of boric acid in deionized water, stir evenly, and prepare 1L of an electroless plating solution with a pH value of 8.

[0055] (5) Soak the cotton gauze sample strip with a metallic nickel activation la...

Embodiment 2

[0058] (1) Use 4 g / L tannic acid solution to assist in the microwave treatment of cotton gauze at medium heat for 2 minutes, take it out, wash with deionized water three times, and dry to obtain tannic acid modified cotton gauze.

[0059] (2) Soak the tannic acid modified cotton gauze in 30 g / L nickel sulfate hexahydrate solution for 10 min, take it out, and obtain the modified cotton gauze with metal nickel ions adsorbed on the surface.

[0060] (3) The modified cotton gauze adsorbed with metal nickel ions was treated with 0.05 mol / L sodium borohydride solution for 120 s, and the metal nickel nanoparticle activation layer was obtained by in-situ reduction.

[0061] (4) Dissolve 25g of nickel sulfate hexahydrate, 25g of sodium dihydrogen phosphate, 30g of sodium citrate, and 60g of boric acid in deionized water, stir evenly, and prepare 1L of an electroless plating solution with a pH value of 9.

[0062] (5) Soak the cotton gauze sample strip with the metallic nickel activatio...

Embodiment 3

[0065] (1) Use a tannic acid solution with a concentration of 6 g / L to treat the cotton gauze in microwave for 3 minutes, take it out, wash it with deionized water three times, and dry it to obtain a tannic acid-modified cotton gauze.

[0066] (2) Soak the tannic acid-modified cotton gauze in 5 g / L nickel sulfate hexahydrate solution for 40 min to obtain the modified cotton gauze with metal nickel ions adsorbed on the surface.

[0067] (3) The modified cotton gauze adsorbed with metallic nickel ions was treated with 0.01 mol / L potassium borohydride solution for 300 s, and the activated layer of metallic nickel nanoparticles was obtained by in-situ reduction.

[0068] (4) Dissolve 30g of nickel sulfate hexahydrate, 30g of sodium dihydrogen phosphate, 15g of sodium citrate, and 70g of boric acid in deionized water, stir evenly, and prepare 1L of an electroless plating solution with a pH value of 8.

[0069] (5) Soak the cotton gauze sample strip with the metallic nickel activati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com