Lithium-sulfur battery positive electrode material as well as preparation method and application thereof

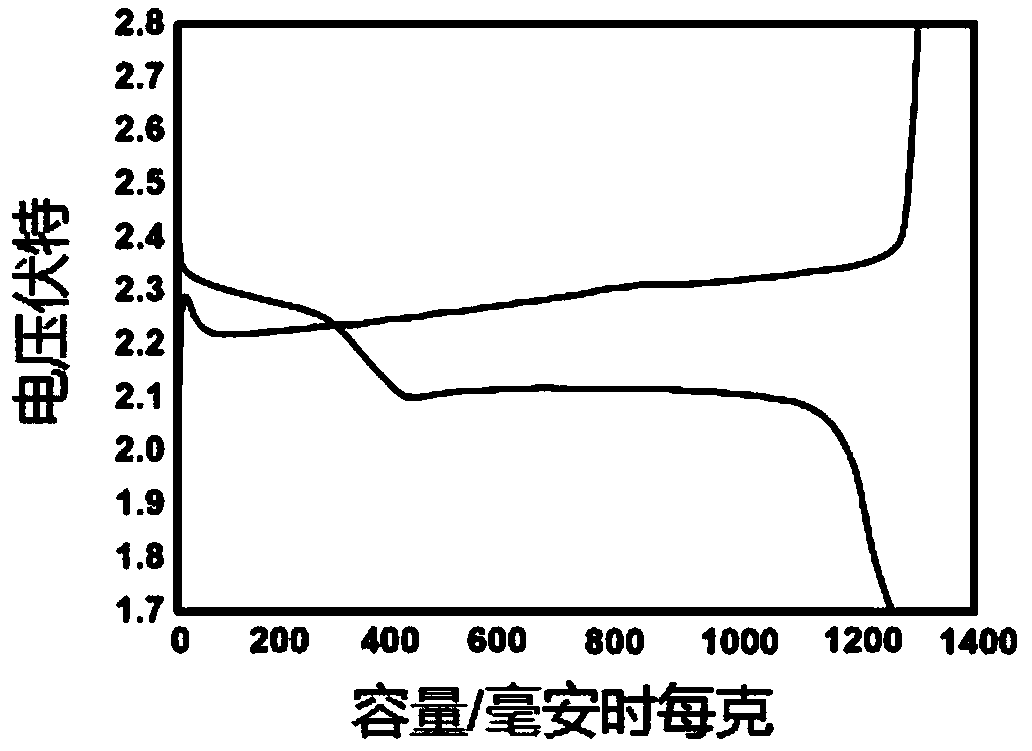

A positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of active material loss and "shuttle effect", restricting the development of lithium-sulfur secondary batteries, and reducing the storage efficiency of charge and discharge , achieving excellent cycle stability, avoiding the shuttle effect, and high discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: A preparation method of lithium-sulfur battery cathode material,

[0028] Step 1: Preparation of precursor solution:

[0029] Dissolve 1.78g of sodium carbonate in 100mL of deionized water, stir for 30min to completely dissolve to obtain a sodium carbonate aqueous solution, then mix the sodium carbonate aqueous solution with 100mL of ammonia water with a concentration of 5moL / L, and stir for 30min until fully mixed to form a uniform mixed solution A .

[0030] Step 2: Preparation of layered porous Zn-Al double hydroxide:

[0031] Put the zinc foil with the size of 30mm×30mm×0.25mm and the carbon-containing aluminum foil with the size of 30mm×30mm×0.15mm into the above homogeneous mixed solution A, and then let it stand at room temperature for 2 days. Take out the carbon-containing aluminum foil from the solution, wash the carbon-containing aluminum foil 4 times with deionized water, and finally dry it in an oven at 60° C. to obtain a layered porous structure Zn-Al d...

Embodiment 2

[0035] Embodiment 2: A preparation method of lithium-sulfur battery cathode material

[0036] Step 1: Preparation of precursor solution:

[0037] Dissolve 1.78g of sodium carbonate in 100mL of deionized water, stir for 30 minutes to completely dissolve to obtain a sodium carbonate aqueous solution, then mix the sodium carbonate aqueous solution with 100mL of ammonia water with a concentration of 10moL / L, and stir for 60 minutes until fully mixed to form a uniform mixed solution A .

[0038] Step 2: Preparation of layered porous Zn-Al double hydroxide:

[0039] Put a zinc foil with a size of 30mm×30mm×0.25mm and a carbon-containing aluminum foil with a size of 30mm×30mm×0.15mm into the above-mentioned homogeneous mixed solution A, and then stand at room temperature for 4 days. Take out the carbon-containing aluminum foil from the solution, wash the carbon-containing aluminum foil 6 times with deionized water, and finally dry it in an oven at 80° C. to obtain a layered porous structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com