Filter stick additive capable of reducing smoke temperature of heat-not-burn cigarette and preparation method of filter stick additive

A heat-not-burn, cigarette filter rod technology, applied in e-liquid filter elements, tobacco, applications, etc., can solve problems such as melting, smoke channel blockage, material cooling difficulties, etc., achieve active material safety, reduce smoke temperature, and prepare The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

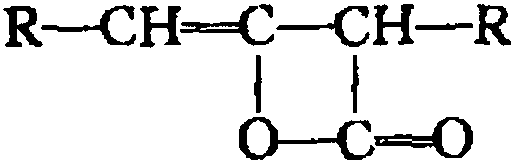

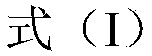

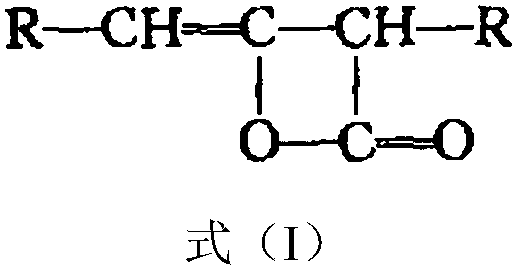

Method used

Image

Examples

Embodiment 1

[0019] Take 1000g of AKD suspension with a solid content of 15% and pour it into a beaker, then add 850g of 20-100 mesh silica gel particles, stir, impregnate for 8h, then dry in a 105°C drying oven for 4h, cool naturally to room temperature, sieve, and take 20-100 mesh particles, that is, AKD / silica gel, put them in a dry box for later use. According to the above preparation method, the AKD suspension was replaced with deionized water, and the other processes were the same to prepare the control silica gel particles.

[0020] The prepared additive was added to cigarette filters at 30 mg / stick, and the smoke test results showed that the maximum smoke temperature of HNB cigarettes containing AKD / silica gel material was 25.5°C lower than that of HNB cigarettes containing control silica gel material.

Embodiment 2

[0022] According to the method of Example 1, the silica gel carrier was replaced with tobacco particles. Others are the same, AKD / tobacco particle material is prepared.

[0023] The prepared additive was added to the cigarette filter at 30mg / stick, and the smoke test results showed that the maximum temperature of the smoke of the heat-not-burn cigarette containing AKD / tobacco particle material was 28.5% lower than that of the heat-not-burn cigarette containing the control tobacco particle material ℃.

Embodiment 3

[0025] According to the method of Example 1, the silica gel carrier was replaced with sodium alginate. Others are the same, AKD / sodium alginate granular material is prepared.

[0026] The prepared additive was added to cigarette filters at 30mg / stick, and the smoke test results showed that the maximum smoke temperature of heat-not-burn cigarettes containing AKD / sodium alginate particulate materials was higher than that of control sodium alginate particulate material heat-not-burn cigarette smoke The maximum temperature is 24.3°C lower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com