Efficient stable supported copper-based catalyst and preparation method thereof

A copper-based catalyst and stable loading technology, which is applied in the field of efficient and stable loaded copper-based hydrogenation catalyst and its preparation, can solve the problems of unstable structure, poor dispersion of copper active components, poor molecular dynamics diffusion performance, etc., and achieve Effects of improved stability, unique structural advantages, and high accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

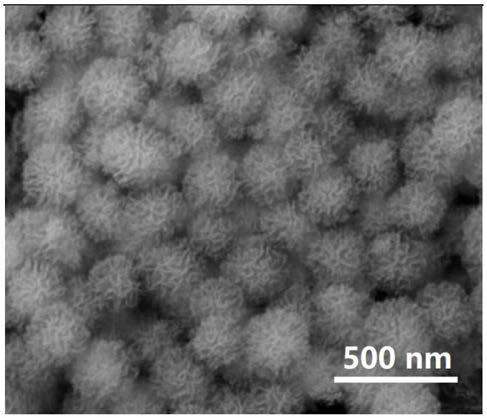

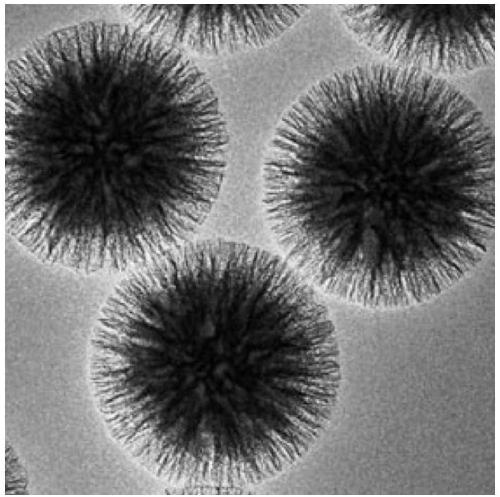

Image

Examples

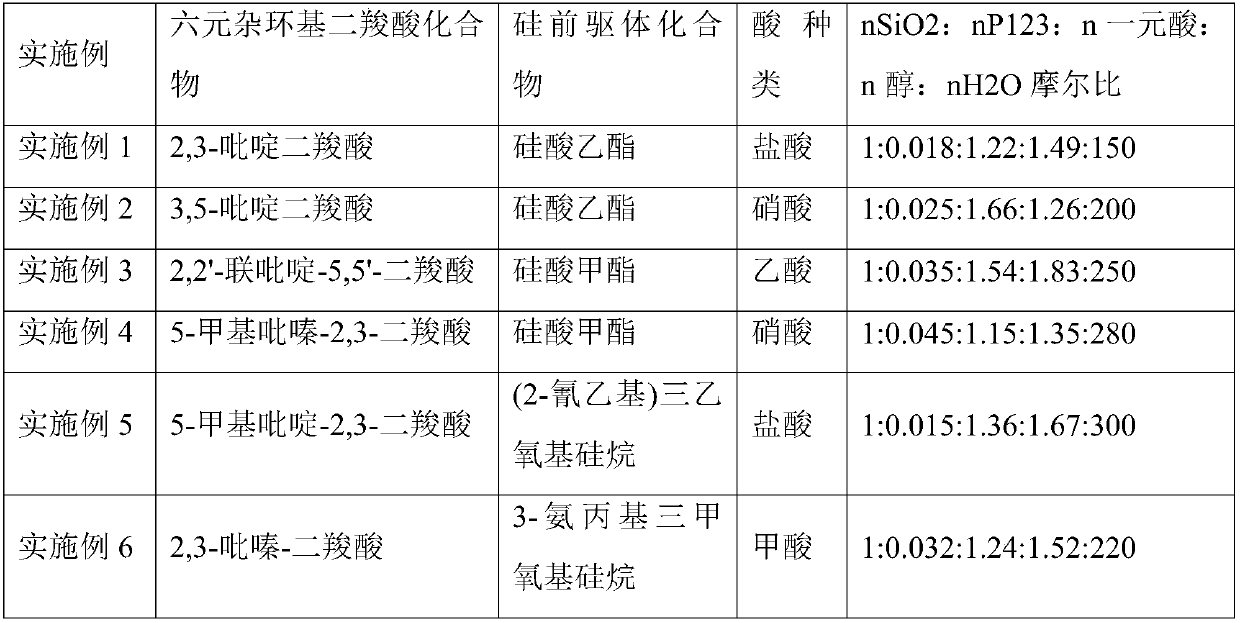

Embodiment 1

[0037] A highly dispersed and stable copper-based catalyst is prepared by the following method:

[0038] 1) Mix 40ml of N,N-dimethylformamide and 100ml of ethanol to form a solution, add 20g of 2,3-pyridinedicarboxylic acid into it and stir until completely dissolved, then add 1.8mol / L Cu( NO 3 )·3H 2 O solution until completely dissolved, continue to stir and disperse at 1500rpm for 1 hour, transfer the mixed solution to a reaction kettle at 120°C for 12 hours; after the reaction is complete, naturally cool to room temperature, filter with suction, wash with distilled water and absolute ethanol three times each, to obtain It is a crystalline solid, and the sample is dried in a vacuum oven at 120°C for 24 hours to obtain a bulk copper-organic coordination material, which is ground into a powder with a particle size of 400 mesh.

[0039] 2) Disperse 15g of copper-organic coordination material solid powder obtained in 1) in 623ml of deionized water to form a suspension, then a...

Embodiment 2

[0042] A highly dispersed and stable copper-based catalyst is prepared by the following method:

[0043] 1) Mix 50ml of N,N-dimethylformamide and 300ml of isopropanol to form a solution, add 20g of 3,5-pyridinedicarboxylic acid into it and stir until completely dissolved, then slowly stir and add 1.08mol / L concentration of Cu(CH 3 COO) 2 ·H 2 O solution until completely dissolved, continue to stir and disperse at 600rpm for 4 hours, transfer the mixed solution to a reaction kettle at 130°C for 24 hours; after the reaction is complete, naturally cool to room temperature, filter with suction, wash with distilled water and absolute ethanol three times each, to obtain Crystalline solid, the sample was dried in a vacuum oven at 105°C for 48 hours to obtain a bulk copper-organic coordination material, which was ground into a 350-mesh powder.

[0044] 2) Disperse 10 g of copper-organic coordination material solid powder obtained in 1) in 305 ml of deionized water to form a suspens...

Embodiment 3

[0046] A highly dispersed and stable copper-based catalyst is prepared by the following method:

[0047] 1) Mix 60ml of N,N-dimethylformamide and 100ml of butanol into a solution, add 20g of 2,2'-bipyridyl-5,5'-dicarboxylic acid into it and stir until completely dissolved, then stir slowly Add 0.41mol / L concentration of CuCl 2 2H 2 O solution until completely dissolved, continue to stir and disperse at 1200rpm for 3 hours, transfer the mixed solution to a reaction kettle at 105°C for 48 hours; after the reaction is complete, naturally cool to room temperature, filter with suction, wash with distilled water and absolute ethanol three times each, to obtain Crystalline solid, the sample was dried in a vacuum oven at 145°C for 12 hours to obtain a bulk copper-organic coordination material, which was ground into a 325-mesh powder.

[0048] 2) Disperse 20 g of copper-organic coordination material solid powder obtained in 1) in 777 ml of deionized water to form a suspension, then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com