cnss-ni@pt/pm-g-c 3 no 4 Electrocatalyst and its preparation method

A pm-g-c3n4, electrocatalyst technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problem of high metal platinum utilization and catalytic activity, high catalytic efficiency, weak oxidation stability of graphene, and reduced carrier conductivity, etc. problems, to achieve the effect of reducing the loss of nanoparticles, improving electrical conductivity, and low platinum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

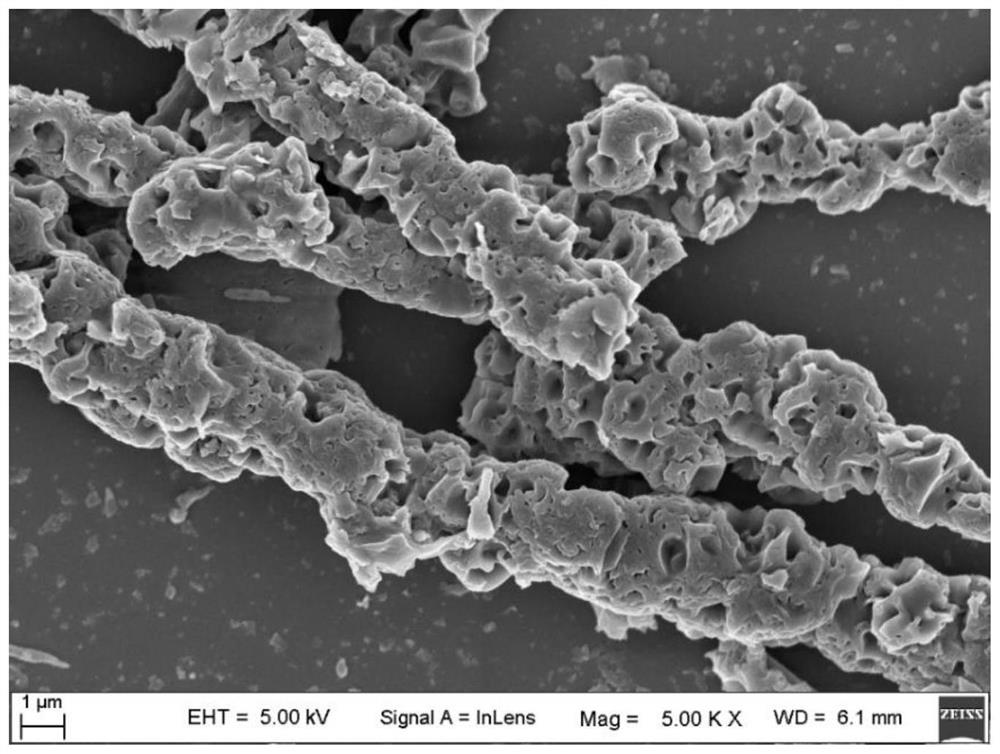

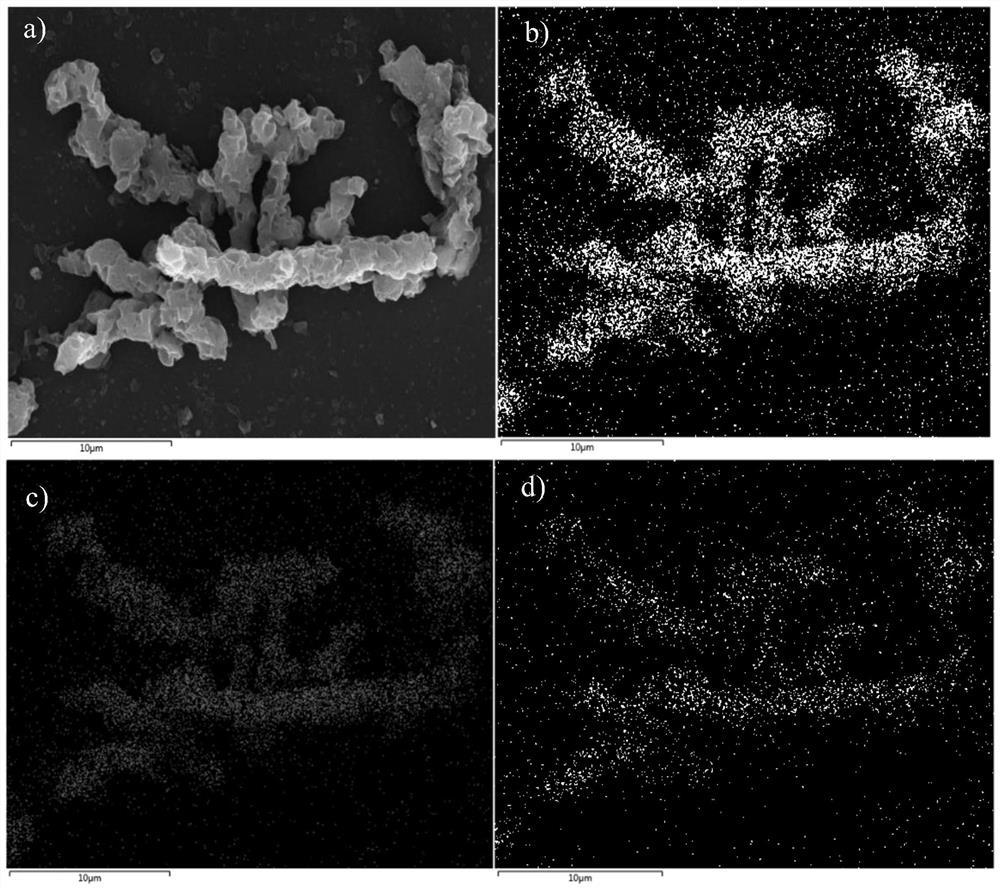

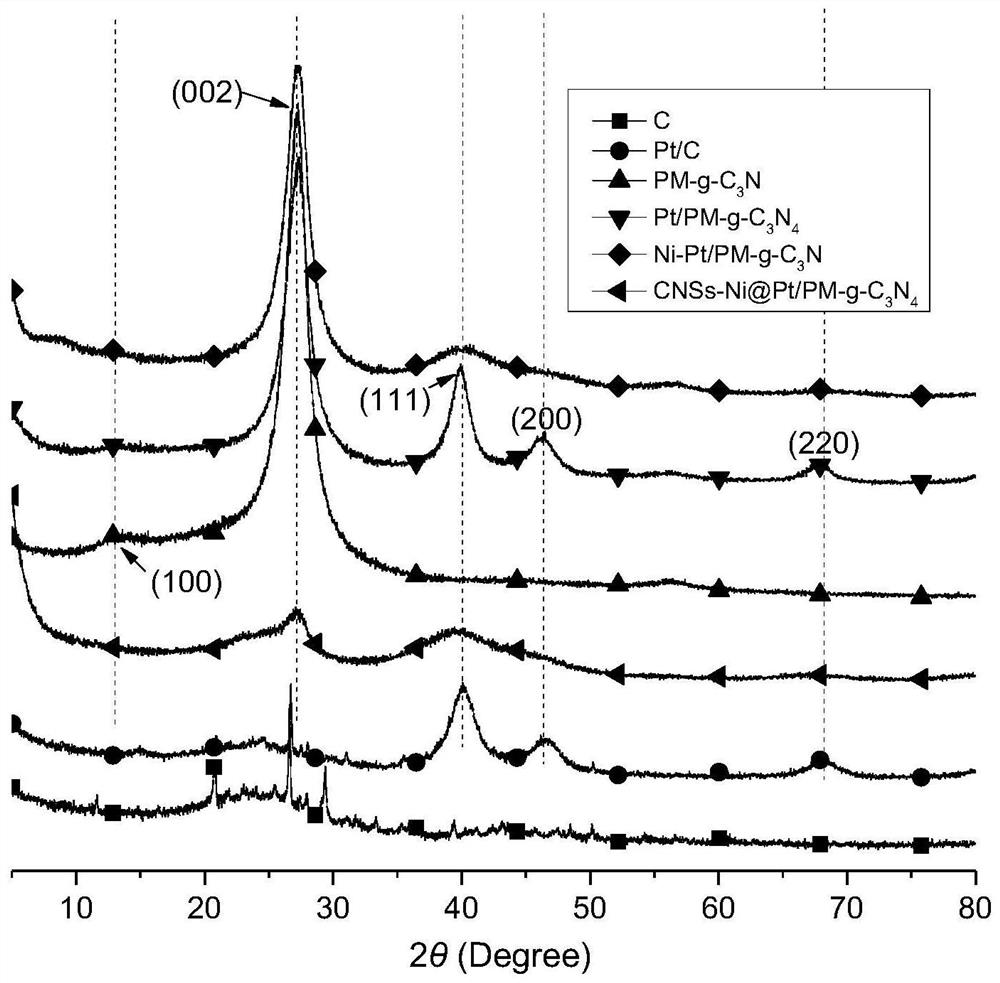

[0043] A sterically stable CNSs-Ni for high temperature fuel cells 3 @Pt / PM-g-C 3 N 4 The preparation method of electrocatalyst, concrete following steps:

[0044] 1) Prepare a 250ml four-necked flask equipped with a nitrogen conduit, a thermometer and a mechanical stirrer, pour 2.0g of melamine (Melamine) and 40ml of ethylene glycol (EG) into the four-necked flask, and heat it in a constant temperature water bath at 50°C Under the condition, feed nitrogen gas and stir at a constant speed of 150rpm. After stirring for 30 minutes, until the melamine is completely dissolved, add 60ml of 0.1M nitric acid to the saturated melamine solution while hot, and continue stirring for 30 minutes until the white precipitate is completely precipitated. The resulting white precipitate was collected for suction filtration, washed three times with deionized water and then three times with absolute ethanol to ensure that the residual nitric acid and ethylene glycol were washed clean. Then the...

Embodiment 2

[0051] A sterically stable CNSs-Ni for high temperature fuel cells 3 @Pt / PM-g-C 3 N 4 The preparation method of electrocatalyst, concrete following steps:

[0052] 1) Prepare a 250ml four-necked flask equipped with a nitrogen conduit, a thermometer and a mechanical stirrer, pour 2.0g of melamine (Melamine) and 50ml of ethylene glycol (EG) into the four-necked flask, and heat it in a constant temperature water bath at 60°C Under certain conditions, feed nitrogen gas and stir at a constant speed of 175rpm. After stirring for 30 minutes, until the melamine is completely dissolved, add 70ml of 0.1 M nitric acid to the saturated melamine solution while hot, and continue stirring for 40 minutes until the white precipitate is completely precipitated. The resulting white precipitate was collected for suction filtration, washed three times with deionized water and then three times with absolute ethanol to ensure that the residual nitric acid and ethylene glycol were washed clean. Th...

Embodiment 3

[0058] A sterically stable CNSs-Ni for high temperature fuel cells 3 @Pt / PM-g-C 3 N 4 The preparation method of electrocatalyst, concrete following steps:

[0059] 1) Prepare a 250ml four-necked flask equipped with a nitrogen conduit, a thermometer and a mechanical stirrer, pour 2.0g of melamine (Melamine) and 60ml of ethylene glycol (EG) into the four-necked flask, and heat it in a constant temperature water bath at 70°C Under certain conditions, feed nitrogen gas and stir at a constant speed of 200rpm. After stirring for 30 minutes, until the melamine is completely dissolved, add 40ml of 0.2 M nitric acid to the saturated melamine solution while hot, and continue stirring for 50 minutes until the white precipitate is completely precipitated. The resulting white precipitate was collected for suction filtration, washed three times with deionized water and then three times with absolute ethanol to ensure that the residual nitric acid and ethylene glycol were washed clean. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com