A kind of fluorination catalyst and its preparation method and application

A technology of fluorination catalyst and metal assistant, which is applied in physical/chemical process catalysts, chemical instruments and methods, halogen substitution preparation, etc. problems such as low conversion rate, to achieve excellent catalytic activity, reduce production costs, and avoid environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

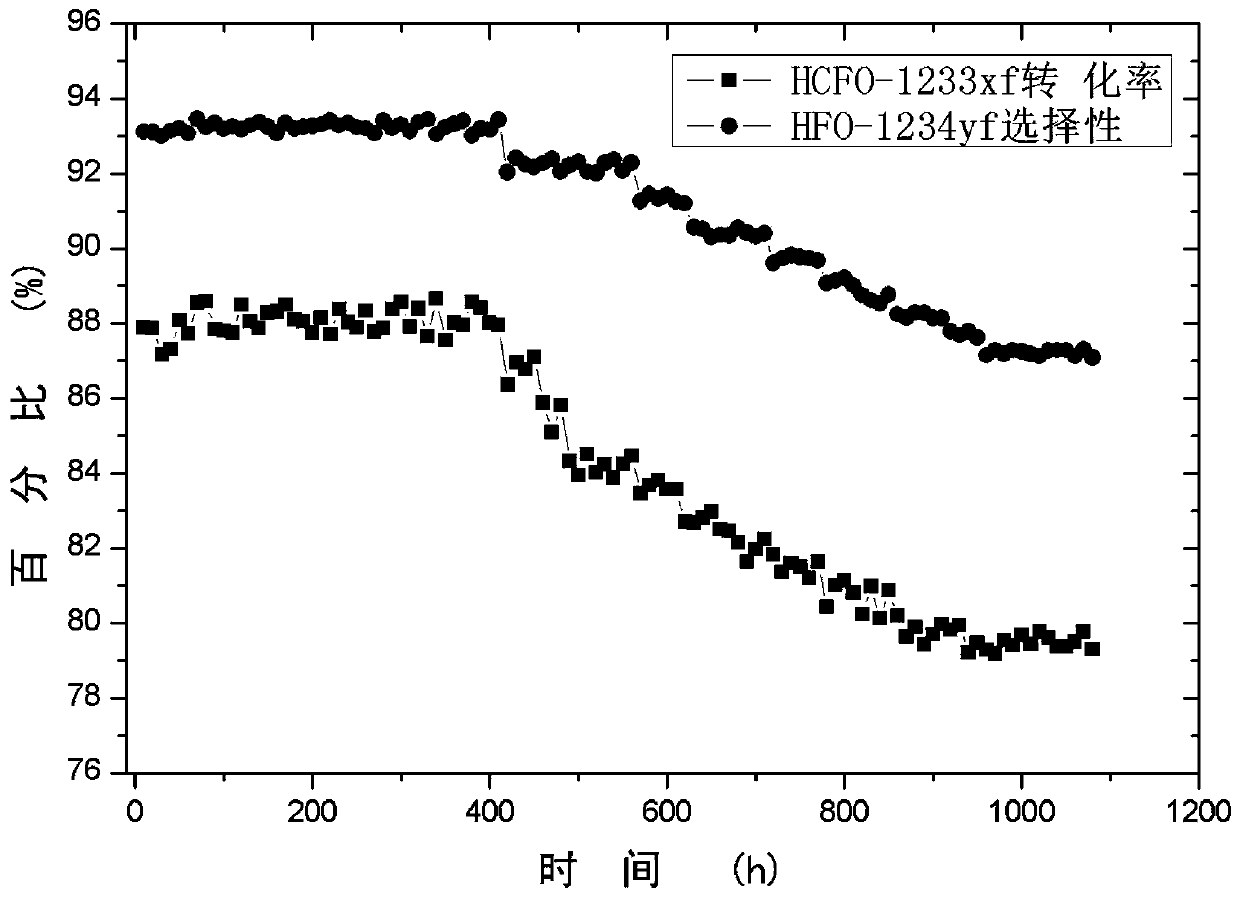

Image

Examples

preparation example Construction

[0049] The invention provides a kind of preparation method of fluorination catalyst, comprises the following steps:

[0050] S1: Grinding metal additive salts and organic ligands and placing them in a microwave oven for microwave reaction to obtain metal additive / organic ligand compounds;

[0051] S2: Roasting the metal additive / organic ligand compound to obtain the metal additive / carbon shell material;

[0052] S3: Blending the metal additive / carbon shell material with chromium oxide, pressing into tablets, calcining, and fluorinating to prepare a fluorination catalyst.

[0053] The invention prepares the metal additive / organic ligand compound through a microwave reaction method, and the microwave reaction provides heat for the metal additive / carbon shell structure to accelerate the reaction, thereby avoiding the use of organic solvents and avoiding environmental pollution.

[0054] According to some embodiments of the present invention, the mass ratio of the metal promoter ...

Embodiment approach

[0066] According to some embodiments of the present invention, the organic ligand is 2,2-biquinoline-4,4-dicarboxylic acid, 2,2-bipyridine-4,4-dicarboxylic acid, 2,2-bipyridine- One or more of 5,5-dicarboxylic acids.

[0067] In some embodiments, the organic ligand is 2,2-bipyridine-4,4-dicarboxylic acid, 2,2-bipyridine-5,5-dicarboxylic acid, 2,2-biquinoline-4, One of the 4-dicarboxylic acids.

[0068] According to some embodiments of the present invention, the grinding time in step S1 is 1-120 min.

[0069] In some embodiments, the grinding time in step S1 is 5-60 min.

[0070] According to some embodiments of the present invention, the microwave power in the microwave reaction in step S1 is 100-1000w, and the microwave reaction time is 1-60min.

[0071] In some embodiments, the microwave power in the microwave reaction in step S1 is 100-1000w, preferably the microwave reaction time is 5-30min.

[0072] In the preparation method provided by the present invention, the calc...

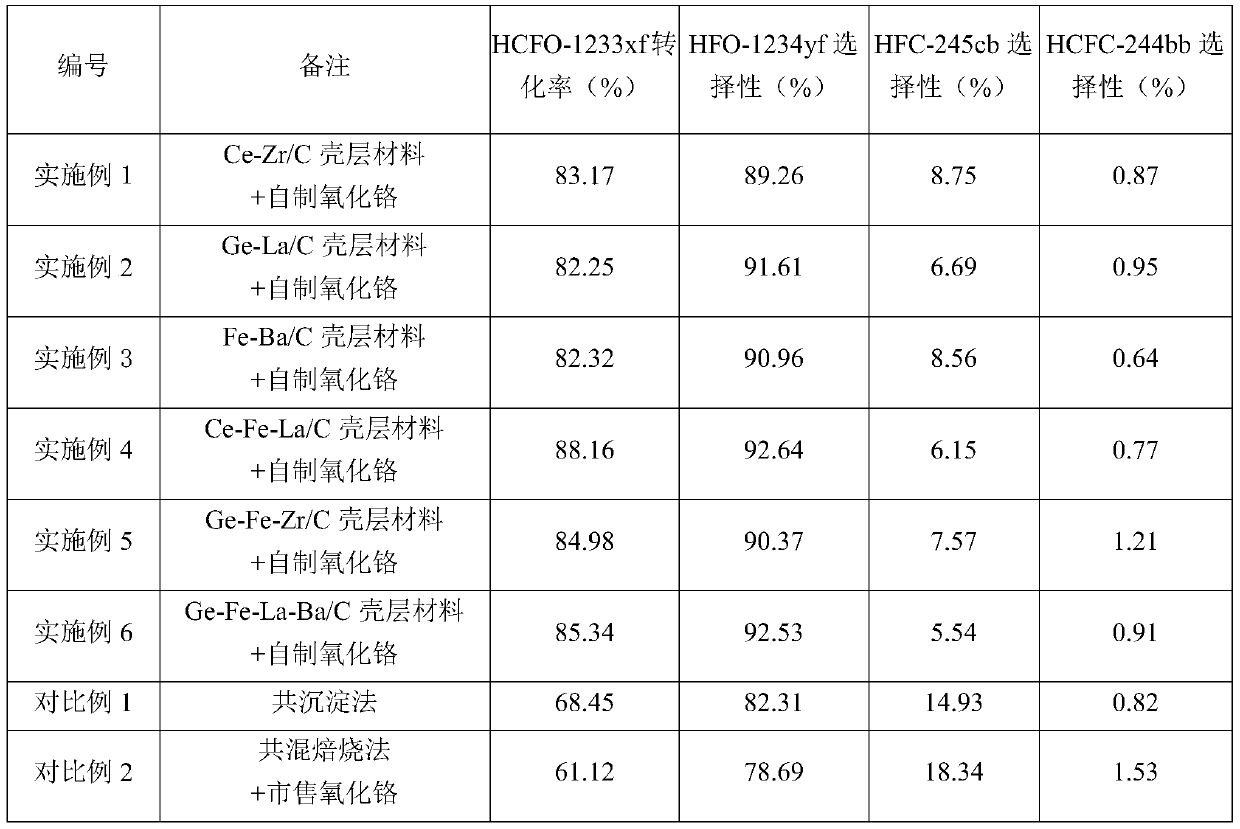

Embodiment 1

[0090] Weigh 6g of cerium nitrate, 3g of zirconium nitrate, and 4.5g of 2,2-bipyridine-4,4-dicarboxylic acid in a mortar, grind for 5 minutes at room temperature, and place in a microwave oven with a power of 1000w for 5 minutes to prepare The metal Ce-Zr / organic ligand compound is obtained; the metal Ce-Zr / organic ligand compound is placed under a nitrogen atmosphere, and roasted at 800°C for 3h to obtain a metal additive / carbon shell material; the metal additive / carbon The shell material was blended with 450g of self-made chromium oxide, pressed into cylindrical particles, calcined at 600°C for 2h in air atmosphere, and finally fluorinated at 400°C for 6h to obtain the HFO-1234yf fluorination catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com