Preparation method of CoCrMo alloy powder for 3D printing

An alloy powder and 3D printing technology, applied in the field of additive manufacturing, can solve the problems of unsuitable 3D printing technology, coarse powder particle size, high powder inclusion content, etc., and achieve proper proportioning relationship, good powder fluidity, and impurity and oxygen content low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method for CoCrMo alloy powder for 3D printing, comprising the following steps:

[0030] (1) Alloy smelting: Vacuum induction smelting is carried out on the CoCrMo alloy raw material to obtain an alloy melt;

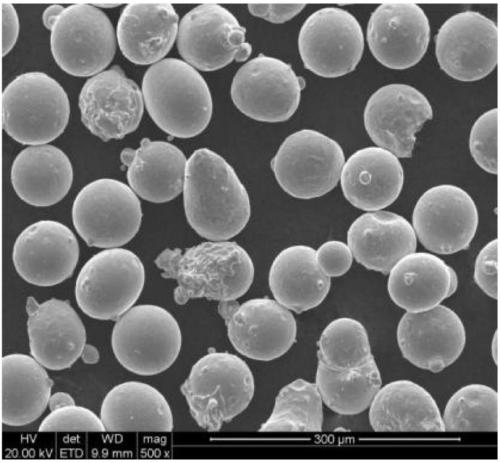

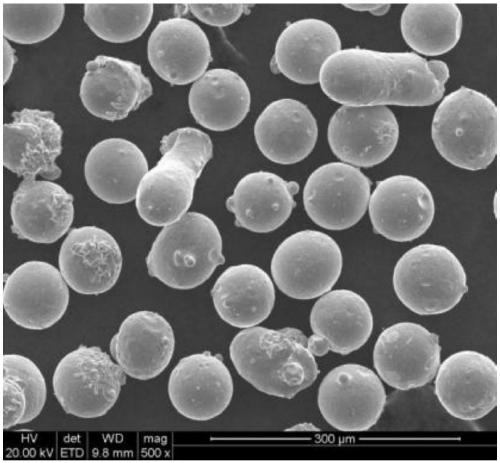

[0031] (2) Atomized pulverization: Pour the alloy melt into the middle leakage bag, open the leakage valve, and the alloy melt flows into the gas atomization furnace freely through the leak hole at the bottom of the middle leakage bag, under the impact of the supersonic airflow , the alloy melt is crushed into fine droplets, cooled and solidified to obtain CoCrMo alloy powder, the powder lands at the bottom of the atomization tower, and then is brought into the powder collection device under the cyclone by the gas;

[0032] (3) Powder screening: the CoCrMo alloy powder obtained in step (2) is subjected to bouncing ball vibration screening; then the powder obtained by vibration screening is carried out to airflow classification;

[0033] In step (1),...

Embodiment 1

[0039] This embodiment is mainly aimed at the alloy raw materials for secondary smelting, and adopts the following steps to prepare CoCrMo alloy powder for SLM technology:

[0040] (1) Alloy remelting: put 50kg of CoCrMo alloy raw material into vacuum induction furnace for melting, the alloy composition is Co: balance, Cr: 27.8%, Mo: 6.2%, Ni≤0.1%, Fe≤0.01%, C≤0.02 %, Si≤0.5%, Mn≤0.2%. The vacuum degree of the melting furnace is 7.8×10 -3 Pa, after the raw materials are completely melted, the temperature of the molten steel is controlled at 1630°C, and the temperature is kept for 20 minutes, while the middle leakage bag is heated to 1180°C;

[0041] (2) Atomization pulverization: open the leakage valve, and the alloy melt flows freely downward into the gas atomization furnace through the leakage hole at the bottom of the middle leakage bag. The atomization pressure in the gas atomization furnace is 2.0MPa. Under the impact of the flow, the alloy melt is crushed into fine dro...

Embodiment 2

[0045] CoCrMo alloy powders for SLM technology were prepared using the following steps:

[0046] (1) Alloy smelting: Put 50kg of CoCrMo alloy raw material into vacuum induction furnace for smelting, the alloy composition is Co: balance, Cr: 28.8%, Mo: 6.1%, Ni≤0.2%, Fe≤0.03%, C≤0.02% , Si≤0.1%, Mn≤0.2%. Melting furnace vacuum degree 9.1×10 -3 Pa, after the raw materials are completely melted, the temperature of the alloy liquid is controlled at 1640°C and kept for 20 minutes, and the middle leakage bag is heated to 1170°C at the same time;

[0047] (2) Atomized pulverization: pour the alloy melt into the middle leakage bag, open the leakage valve, the alloy melt flows freely downward into the gas atomization furnace through the leakage hole at the bottom of the middle leakage bag, and the mist in the gas atomization furnace The melting pressure is 3.0MPa. Under the impact of high-purity nitrogen flow, the alloy melt is crushed into fine droplets, and after cooling and solidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com