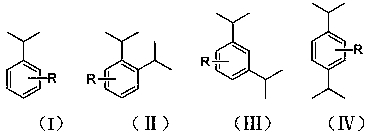

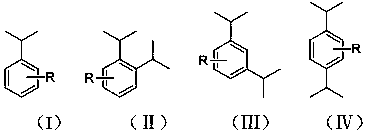

Method of preparing aromatic isopropyl hydrogen peroxide compounds by microchannel oxidation process

A propyl hydroperoxide and compound technology, which is applied in the preparation of peroxy compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of high reaction safety factor, high production cost, short reaction time, etc. Good quality and heat transfer effect, short reaction time, and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 32.4 g (200 mmol) of m-dicumene (200 mmol), 3.3 g (20 mmol) of N-hydroxyphthalimide, 1 g (6 mmol) of azobisisobutyronitrile and 200 mL of acetonitrile into the preheater, Mix and dissolve, and preheat to 60°C to obtain a reaction raw material solution for use.

[0024] The temperature of the JD-SSIC silicon carbide plate microchannel reactor was raised to 75°C, and oxygen was introduced, the pressure was 2.6Mpa, and the flow rate of oxygen was 0.2mL / min. Feed into the reaction raw material liquid, the flow rate is 30mL / min, after the reacted feed liquid is subjected to gas-liquid separation, the separated reaction mixture is passed into the microchannel reactor for cyclic reaction, the one-way reaction time is 2min, and the cumulative reaction time is 180min. Finally, the cumene m-dihydroperoxide solution was obtained, which was analyzed by a liquid chromatograph, and the yield was 49%, and the selectivity was 92.1%.

Embodiment 2

[0026] 4.2 g (20 mmol) of N-hydroxy-4-nitrophthalimide was used instead of 3.3 g (20 mmol) of N-hydroxyphthalimide, and other reaction conditions and operating procedures were the same as in Example 1. A cumene m-dihydroperoxide solution was obtained with a yield of 43.2% and a selectivity of 90.2%.

Embodiment 3

[0028] 4.0 g (20 mmol) of N-hydroxy-4-chlorophthalimide was substituted for 3.3 g (20 mmol) of N-hydroxyphthalimide, and the other reaction conditions and operating procedures were the same as in Example 1. A cumene m-dihydroperoxide solution was obtained with a yield of 43.8% and a selectivity of 90.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com