Phosphorus-containing polyethylene and maleic anhydride graft copolymer with synergistic flame-retardant effects and method for preparing phosphorus-containing polyethylene and maleic anhydride graft copolymer

A technology of graft copolymer and maleic anhydride, which is applied in the field of phosphorus-containing polyethylene maleic anhydride graft copolymer and its preparation, can solve the problem of poor compatibility, decreased mechanical properties of materials, a large amount of toxic gas and dense smoke and other problems, to achieve good flame retardant effect, reduce dosage, and excellent coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

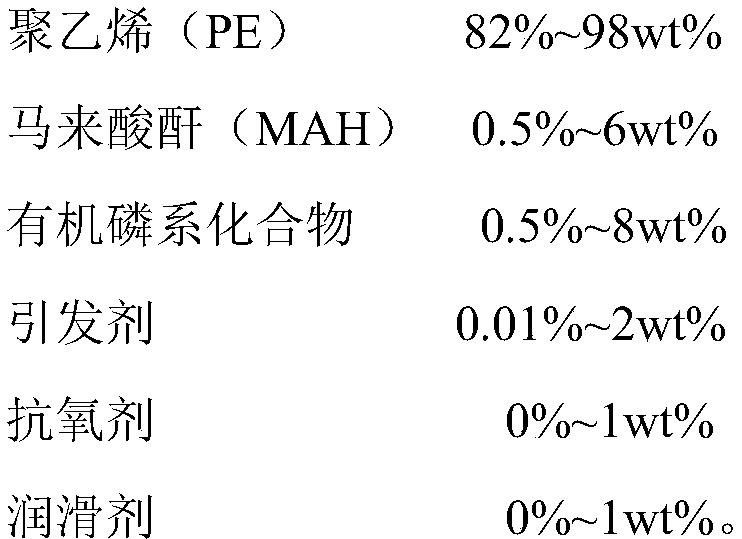

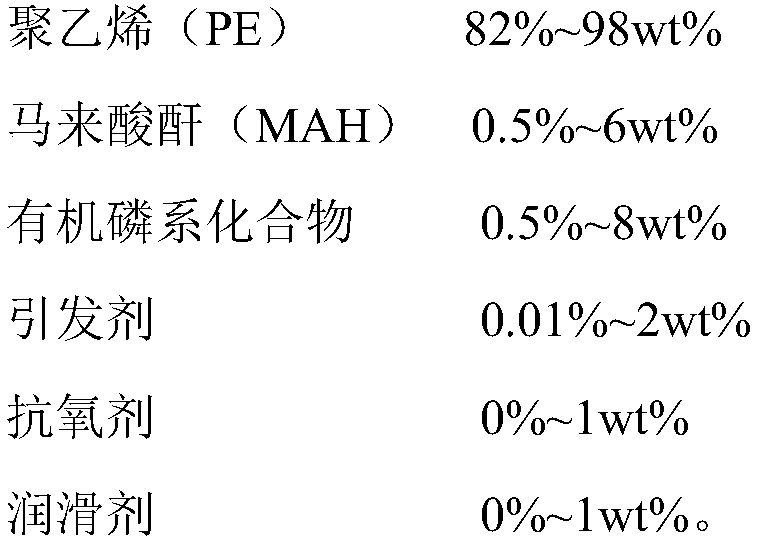

[0035] The preparation method of the described phosphorus-containing polyethylene maleic anhydride graft copolymer with synergistic flame retardant effect may further comprise the steps:

[0036] Step A, polyethylene, part initiator, antioxidant and lubricant are added to the low-speed mixing mixer and fully mixed;

[0037] Step B. Add the mixture obtained in Step A to the twin-screw extruder through the main feeding port, and the organophosphorus compound is injected into the extruder from the liquid pump system; then add maleic anhydride and the remaining initiator through side feeding Extruder, melt extrusion, granulation.

[0038] The processing temperature of the extruder is 100°C-200°C, the rotation speed of the main machine is 180-400rpm, and the aspect ratio of the reactive extruder is greater than 48.

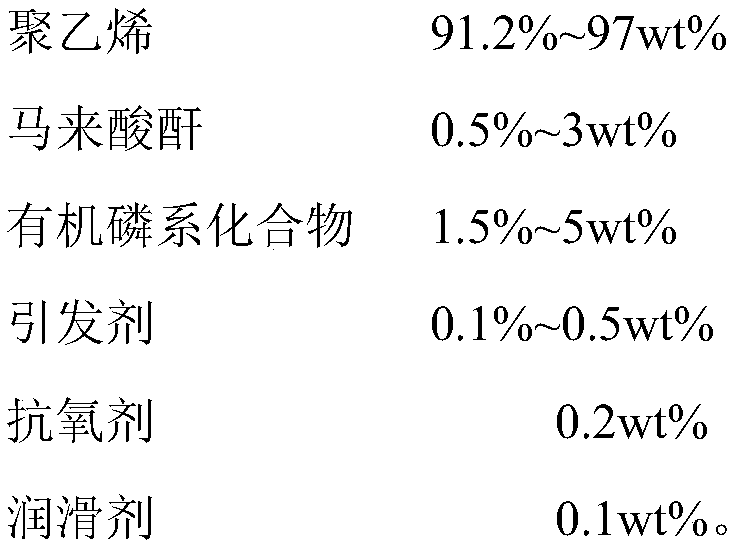

Embodiment 1

[0040] Take the following components by weight: 91.2 parts of PE, 3 parts of maleic anhydride, 5 parts of triethyl-4-phosphide, 0.5 part of dicumyl peroxide, antioxidant 1010 and antioxidant 168 0.2 parts, lubricant 0.1 parts. Add polyethylene, 0.3 parts of dicumyl peroxide, antioxidant and lubricant into the low-speed mixing mixer, blend for 10 minutes, make it fully mixed, and then add it to the twin-screw extrusion through the main feeding port In the machine; triethyl-4-phosphide is injected into the extruder through a liquid pump; the remaining dicumyl peroxide and maleic anhydride are fully mixed and fed into the extruder by side feeding. The temperature of each zone of the extruder is set to 100°C, 120°C, 150°C, 170°C, 175°C, 180°C, 180°C, 180°C, 180°C, 175°C, 175°C, 170°C, and the length-to-diameter ratio of the extruder is 48. The rotating speed of the main machine is 260rpm. The mixed material is melted and plasticized, kneaded and mixed, extruded by the head, water...

Embodiment 2

[0042]Take the following components by weight: 94.4 parts of PE, 2 parts of maleic anhydride, 3 parts of triethyl-4-phosphide, 0.3 part of dicumyl peroxide, antioxidant 1076 and antioxidant 168 0.2 parts, lubricant 0.1 parts. Add polyethylene, 0.2 parts of dicumyl peroxide, antioxidant and lubricant into the low-speed mixing mixer, blend for 10 minutes, make it fully mixed, and then add it to the twin-screw extrusion through the main feeding port In the machine; triethyl-4-phosphide is injected into the extruder through a liquid pump; the remaining dicumyl peroxide and maleic anhydride are fully mixed and fed into the extruder by side feeding. The temperature of each zone of the extruder is set to 100°C, 120°C, 150°C, 170°C, 180°C, 185°C, 185°C, 185°C, 185°C, 180°C, 180°C, 170°C, and the length-to-diameter ratio of the extruder is 48. The speed of the host machine is 260rpm. The mixed material is melted and plasticized, kneaded and mixed, extruded by the head, water-cooled, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com