Method for preparing phenolic resin by adopting pyrrole acidic ionic liquid as catalyst

A technology of acidic ionic liquid and phenolic resin, which is applied in the field of ionic liquid catalysis, can solve the problems of low catalyst activity, long time consumption, and low yield, and achieve the effects of good selectivity, high yield, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add the N-methylpyrrolidone of 0.1mol in the 250ml four-neck flask with mechanical stirring device, slowly add the 98% sulfuric acid of the amount of equal substance with constant pressure funnel under ice bath, control rate at 10s / drop, in case The reaction was too violent; after the dropwise addition was completed, it was stirred in a water bath at 60°C for 24h. The obtained liquid was repeatedly washed three times with ethyl acetate, and after rotary evaporation and vacuum drying, a light yellow viscous ionic liquid (1) N-methylpyrrolidone bisulfate ([Hnmp]HSO 4 ).

[0022] Add phenol (P) and formaldehyde (F) with a molar ratio of 1:0.75 in a 1000ml three-neck flask equipped with a condensing reflux tube and a stirrer, use pyrrole acidic ionic liquid as a catalyst, and add 0.2wt% ionic liquid (1) Heat to reflux state while stirring, keep this state for 2 hours, then add 8wt% polyvinyl alcohol (PVA) aqueous solution, keep reflux state and continue to stir and disper...

Embodiment 2

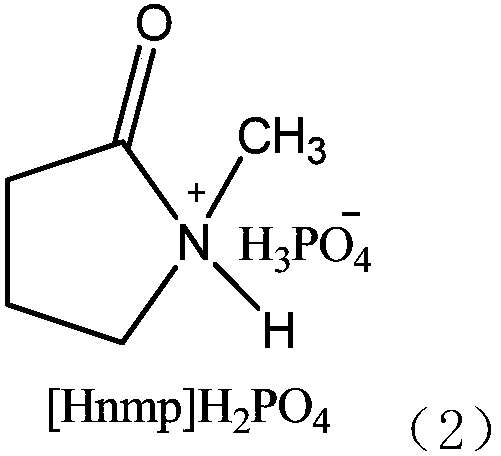

[0024] Add 0.1mol of N-methylpyrrolidone in a 250ml four-necked flask with a mechanical stirring device, and slowly add 80% phosphoric acid with a constant pressure funnel under an ice bath to control the rate at 10s / drop to prevent The reaction was too violent; after the dropwise addition was completed, it was stirred in a water bath at 60°C for 24h. The obtained liquid was repeatedly washed three times with ethyl acetate, and after rotary evaporation and vacuum drying, a light yellow viscous ionic liquid (2) N-methylpyrrolidone bisulfate ([Hnmp]HSO 4 ).

[0025] In the 1000ml there-necked flask that condensing reflux tube, stirrer are equipped with, add the resorcinol (P), formaldehyde (F) that mol ratio is 1:0.9, take pyrrole acidic ionic liquid as catalyst, add 0.3wt% ionic liquid ( 2) heating to reflux state while stirring, keep this state for 0.5h, then add 8wt% polyvinyl alcohol (PVA) aqueous solution, keep reflux state and continue to stir and disperse for 40min, fina...

Embodiment 3

[0028] Add 0.1mol of N-methylpyrrolidone in a 250ml four-necked flask with a mechanical stirring device, and slowly add the p-toluenesulfonic acid aqueous solution of the amount of the same substance with a constant pressure funnel under ice bath, and control the rate at 10s / drop, In case the reaction is too violent; after the dropwise addition, stir in a water bath at 60°C for 24h. The obtained liquid was repeatedly washed three times with ethyl acetate, and after rotary evaporation and vacuum drying, a light yellow viscous ionic liquid (3) N-methylpyrrolidone bisulfate ([Hnmp]HSO 4 ).

[0029] Add p-cresol (P) and formaldehyde (F) with a molar ratio of 1:0.8 in a 1000ml three-necked flask equipped with a condensing reflux tube and a stirrer, use pyrrole acidic ionic liquid as a catalyst, and add 0.5wt% ionic liquid (3) Heat to reflux state while stirring, keep this state for 1.0h, then add 8wt% polyvinyl alcohol (PVA) aqueous solution, keep reflux state and continue stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com