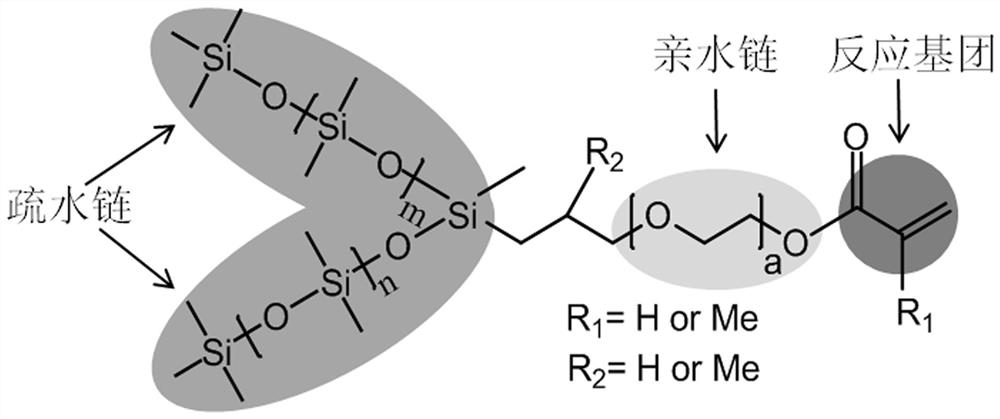

A kind of v-shaped polydimethylsiloxane polyoxyethylene ether monoacrylate and preparation method thereof

A technology of dimethylsiloxane polyoxyethylene ether and dimethylsiloxane, which is applied in the field of polymer synthesis, can solve the problems of high price, unfavorable research and promotion of high-performance associative thickeners, etc. The raw materials are easily available, which is beneficial to industrial production and commercial promotion and application, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

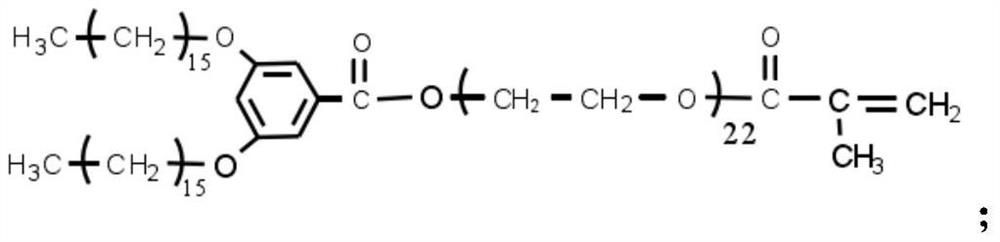

[0041] Add 0.75 parts of 1,1,1,3,5,5,5-heptamethyltrisiloxane, 10.0 parts of octamethylcyclotetrasiloxane, 0.1 part of solid superacid SO 4 -2 / TiO 2 , raise the temperature to 70°C for 4 hours, continue to heat up to 160°C after filtration, and keep it under the condition of vacuum degree -0.09Mpa for 2h to remove the low boilers, that is, to obtain the side hydrogen-containing polysiloxane oligomer intermediate, which contains The value of m in the hydrogen polysiloxane oligomer intermediate is 20, and the value of n is 20. The raw material composition and reaction conditions for the preparation of the hydrogen polysiloxane oligomer intermediate are detailed in Table 1.

[0042] Add 3.2 parts of the obtained pendant hydrogen-containing polysiloxane oligomer intermediate, 2.4 parts of allyl alcohol polyoxyethylene ether APEG2000, and 100 mg / Kg of chloroplatinic acid catalyst (relative reactant), react at 120 ° C for 4 h to obtain V Shaped polydimethylsiloxane-polyethylene g...

Embodiment 2

[0047] Add 0.75 parts of 1,1,1,3,5,5,5-heptamethyltrisiloxane, 1.0 parts of octamethylcyclotetrasiloxane, 0.03 parts of solid superacid SO 4 -2 / ZrO 2 , raise the temperature to 80°C for 2 hours, continue to heat up to 160°C after filtration, and keep it under the condition of vacuum degree -0.09Mpa for 2h to remove the low boilers, that is, to obtain the side hydrogen-containing polysiloxane oligomer intermediate, which contains The value of m in the hydrogen polysiloxane oligomer intermediate is 2, and the value of n is 2. See Table 1 for the raw material composition and reaction conditions for the preparation of the hydrogen polysiloxane oligomer intermediate.

[0048] Add 5.2 parts of the obtained pendant hydrogen-containing polysiloxane oligomer intermediate, 1.0 part of allyl alcohol polyoxyethylene ether APEG1000, 50 mg / Kg of chloroplatinic acid catalyst (relative reactant), and react at 80 ° C for 6 h to obtain V Shaped polydimethylsiloxane-polyethylene glycol capped...

Embodiment 3

[0052] Add 0.75 parts of 1,1,1,3,5,5,5-heptamethyltrisiloxane, 8.0 parts of octamethylcyclotetrasiloxane, 0.04 parts of solid superacid SO 4 -2 / Fe 2 o 3 , heated up to 60°C for 4h reaction, continued to heat up to 160°C after filtration, and kept for 2h under the condition of vacuum degree -0.09Mpa to remove low boilers, that is, to obtain the side hydrogen-containing polysiloxane oligomer intermediate, which side contains The value of m in the hydrogen polysiloxane oligomer intermediate is 16, and the value of n is 16. The raw material composition and reaction conditions for the preparation of the hydrogen polysiloxane oligomer intermediate are detailed in Table 1.

[0053] Add 2.6 parts of the obtained side hydrogen-containing polysiloxane oligomer intermediate, 2.4 parts of allyl alcohol polyoxyethylene ether HPEG2400, 40mg / Kg of vinylsiloxane-platinum complex (relative reactant), in React at 100°C for 4 hours to obtain a V-shaped polydimethylsiloxane-polyethylene glyco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com