Non-catalytic efficient preparation method of two-dimensional fluorine-containing covalent organic framework compound

A covalent organic framework and compound technology, which is applied in the field of non-catalytic and efficient preparation of two-dimensional fluorine-containing covalent organic framework compounds, can solve the problems of long reaction time, difficulty in synthesizing crystalline products, and the need for catalysts, etc., and achieve a simple reaction process , high yield, enhanced electrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

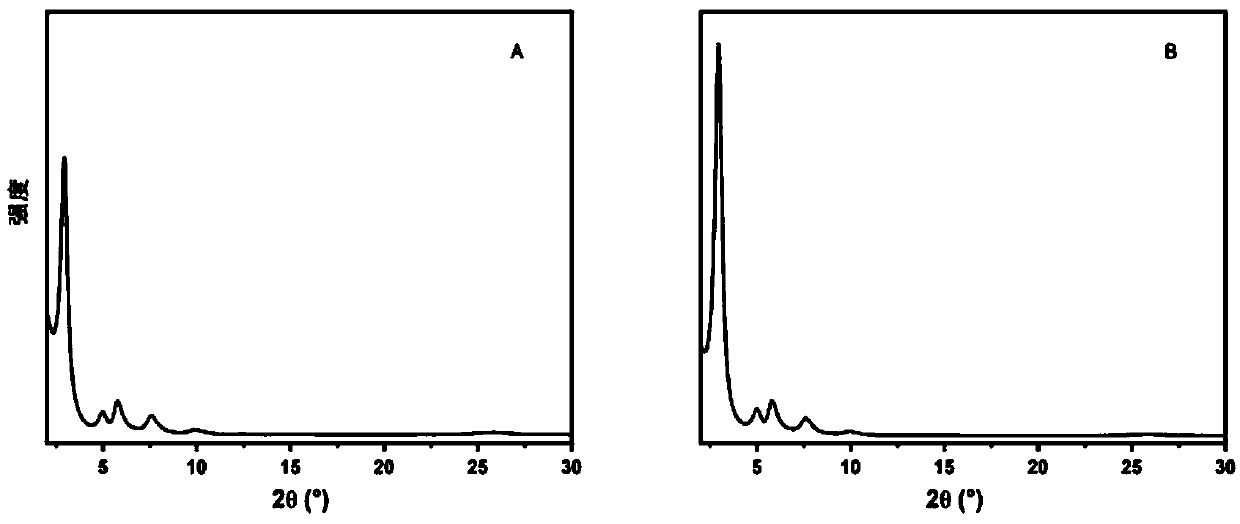

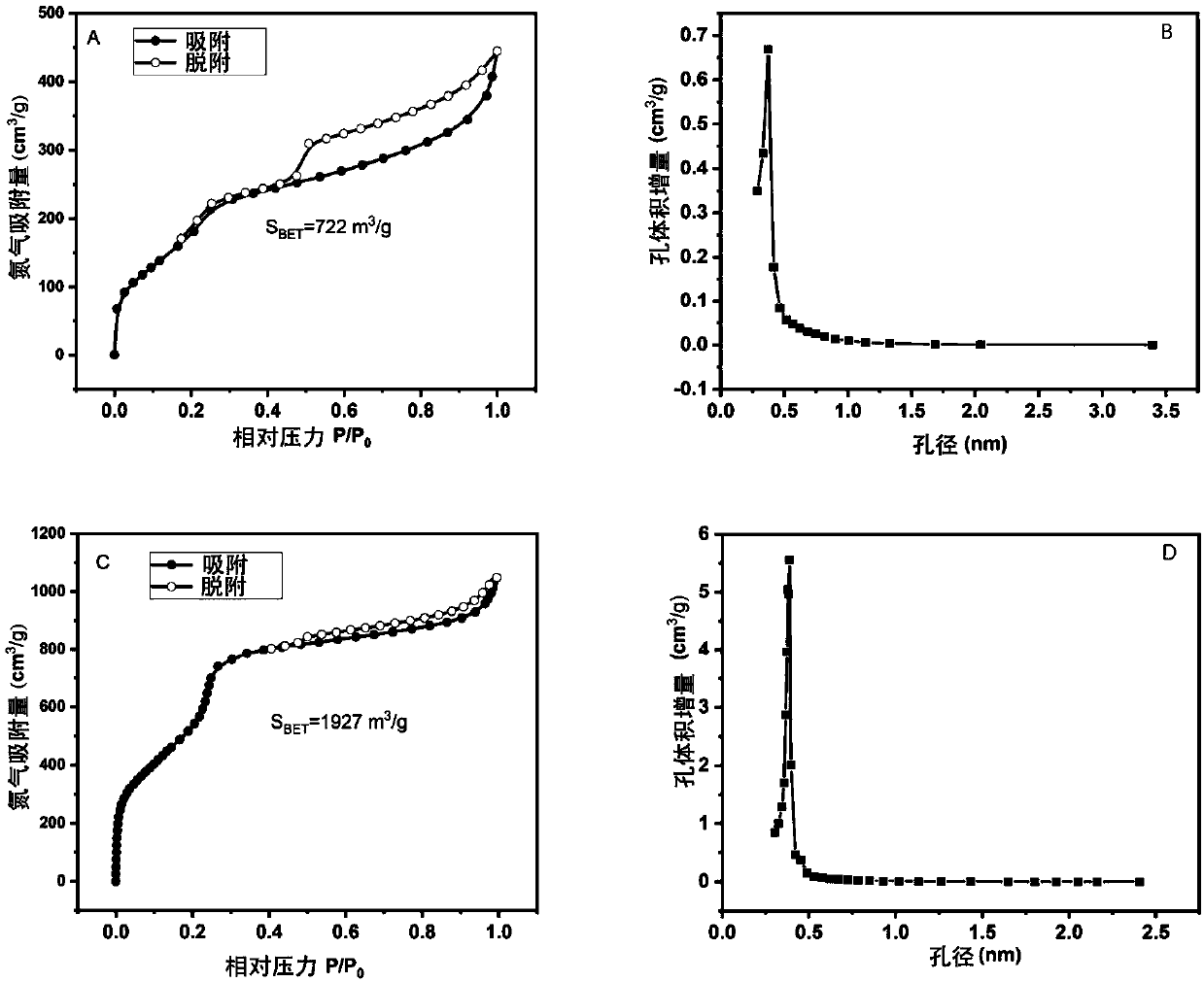

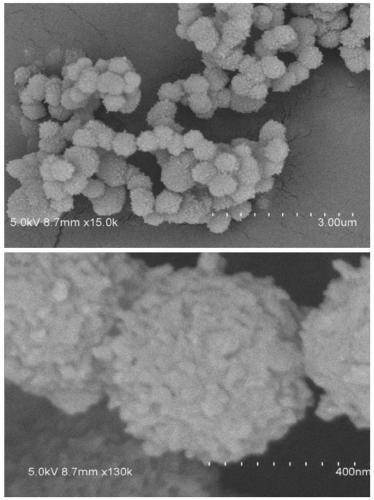

Embodiment 1

[0034] A non-catalytic and efficient preparation method of a two-dimensional fluorine-containing covalent organic framework compound, comprising the following steps:

[0035] 1) Weigh 2,3,5,6-tetrafluoroterephthalaldehyde (82.4mg) and 2,4,6-tris(4-aminophenyl)-1,3,5 with a molar ratio of 1:1.5 - Triazine (94.4mg) in a 2mL heat-resistant glass tube, add 1mL dioxane / mesitylene (v / v=1:1) solvent;

[0036] 2) Freeze the glass tube with liquid nitrogen, evacuate to 0 mbar for three minutes, degas, repeat three times, and seal the vacuum glass tube; ultrasonicate the glass tube for 20 minutes, put it in a 120°C oven for 5 minutes, and obtain the crude product;

[0037] 3) The crude product was taken out and filtered, washed with tetrahydrofuran solution, drained, wrapped with clean filter paper, put into a Soxhlet extractor, and washed with tetrahydrofuran solution at 100°C for 12 hours under reflux;

[0038] 4) Take out the product after reflux washing, and put it into the separat...

Embodiment 2

[0040] A non-catalytic and efficient preparation method of a two-dimensional fluorine-containing covalent organic framework compound, comprising the following steps:

[0041] 1) Weigh 2,3,5,6-tetrafluoroterephthalaldehyde (82.4mg) and 2,4,6-tris(4-aminophenyl)-1,3,5 with a molar ratio of 1:1.5 - Triazine (94.4mg) in a 2mL heat-resistant glass tube, add 1mL dioxane / mesitylene (v / v=1:1) solvent;

[0042] 2) Freeze the glass tube with liquid nitrogen, evacuate to 0 mbar for three minutes, degas, repeat three times, and seal the vacuum glass tube. Sonicate the glass tube for 20 minutes, and put it in a 120°C oven for 24 hours to obtain the crude product;

[0043] 3) The crude product was taken out and filtered, washed with tetrahydrofuran solution, drained, wrapped with clean filter paper, put into a Soxhlet extractor, and washed with tetrahydrofuran solution at 100°C for 12 hours under reflux;

[0044] 4) Take out the product after reflux washing, and put it into the separation...

Embodiment 3

[0053] A non-catalytic and efficient preparation method of a two-dimensional fluorine-containing covalent organic framework compound, comprising the following steps:

[0054] 1) Weigh 2,3,5,6-tetrafluoroterephthalaldehyde (82.4mg) and 2,4,6-tris(4-aminophenyl)-benzene (93.6mg) with a molar ratio of 1:1.5 In a 2mL heat-resistant glass tube, add 1mL of dioxane / mesitylene (v / v=1:1) solvent;

[0055] 2) Freeze the glass tube with liquid nitrogen, evacuate to 0 mbar for three minutes, degas, repeat three times, and seal the vacuum glass tube. The glass tube was sonicated for 20 minutes, and placed in an oven at 180° C. for 1 minute to obtain a crude product.

[0056] 3) The crude product was taken out and filtered, washed with tetrahydrofuran solution, drained, wrapped with clean filter paper, put into a Soxhlet extractor, and washed with tetrahydrofuran solution at 100°C for 12 hours under reflux;

[0057] 4) Take out the product after reflux washing, and dry it (put it in an ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com