Method of controlling orientation of nano structure

A nanostructure and orientation technology, applied in the field of materials, can solve the problems of high industrial manufacturing costs, high integration and miniaturization of hardware, and achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

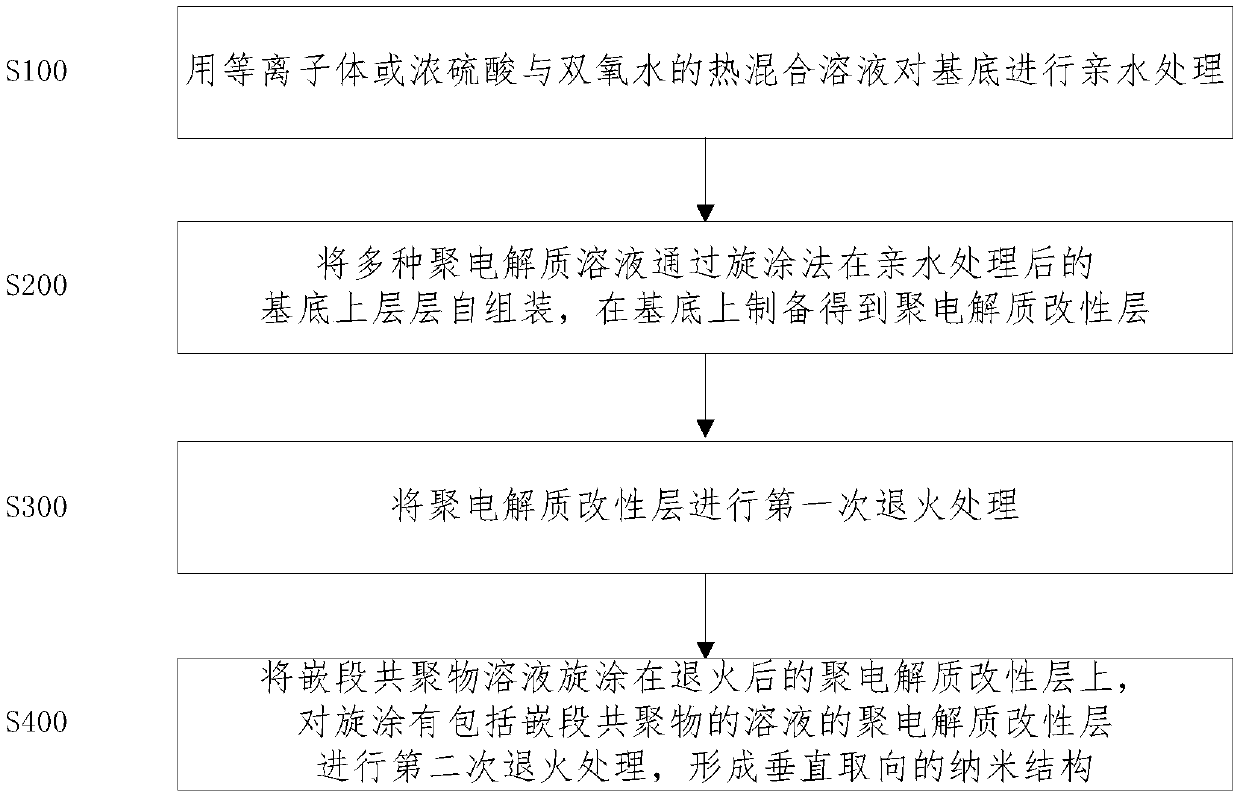

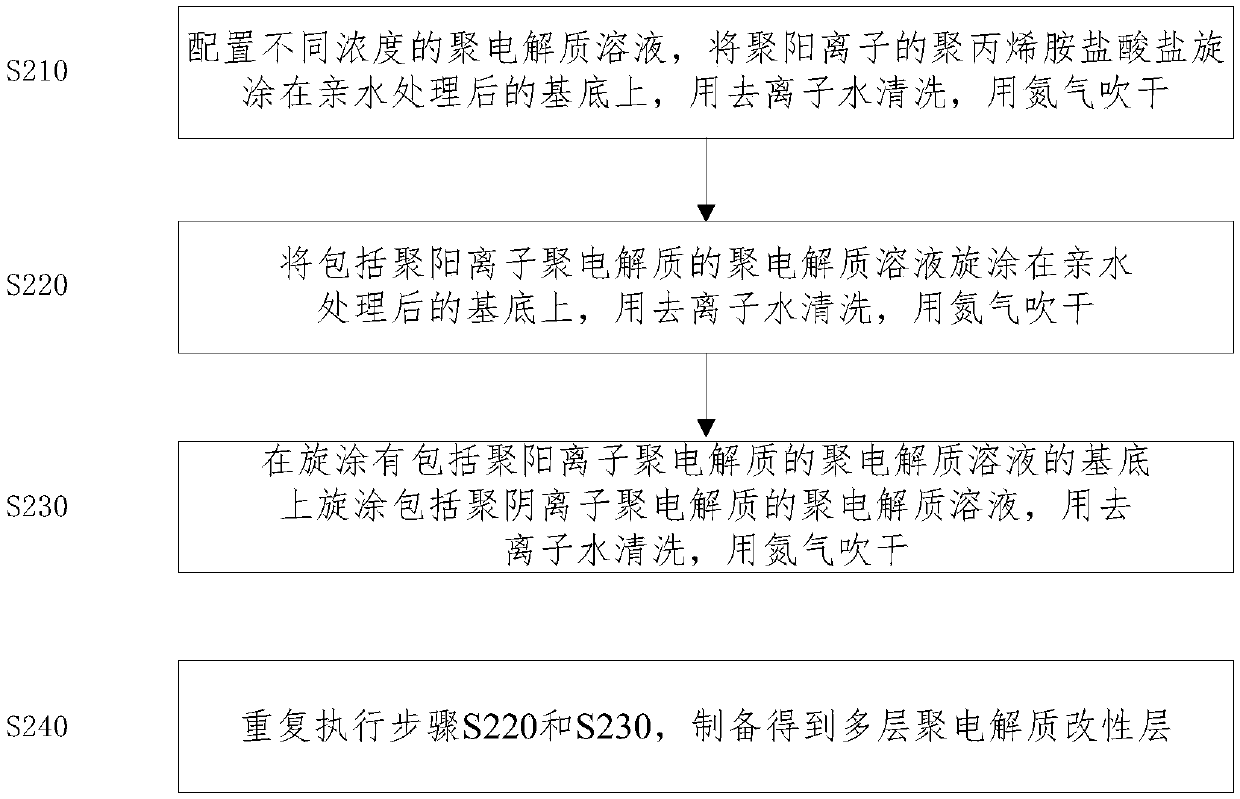

[0041] Please refer to figure 2 , the preparation method of polyelectrolyte modified layer comprises:

[0042] S210, respectively configuring a polyelectrolyte solution including a polycation polyelectrolyte and a polyelectrolyte solution including a polyanion polyelectrolyte.

[0043] S220, spin-coat the polyelectrolyte solution including polycation polyelectrolyte on the substrate after hydrophilic treatment, wash with deionized water, and dry with nitrogen gas.

[0044] S230, spin-coat the polyelectrolyte solution including polyanion polyelectrolyte on the substrate on which the polyelectrolyte solution including polycation polyelectrolyte is spin-coated, wash with deionized water, and blow dry with nitrogen.

[0045] S240, repeat steps S220 and S230 to prepare multiple polyelectrolyte modified layers.

[0046] Optionally, nitrogen is high-purity nitrogen. Nitrogen has stable chemical properties and low cost, which can effectively reduce costs.

[0047] Polyelectrolyte...

Embodiment

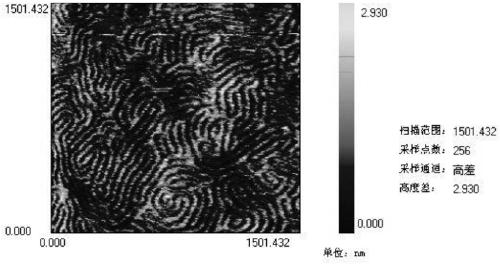

[0073] Example: polyelectrolyte layer self-assembly induces PS-b-PMMA to form a "layered" ordered nanostructure perpendicular to the direction of the substrate, required raw materials: polypropylene amine hydrochloride, polyacrylic acid, PS-b-PMMA embedded segment copolymer, toluene, deionized water. Specific steps are as follows:

[0074] 1. Preparation of polyelectrolyte layer-by-layer self-assembly modified layer

[0075] Hydrophilic treatment of the substrate with plasma or a hot mixed solution of concentrated sulfuric acid and hydrogen peroxide for 1 hour.

[0076] Prepare polyacrylic acid deionized water solution and polyacrylamine hydrochloride deionized water solution.

[0077] Spin-coat the polyallylamine hydrochloride solution on the hydrophilic silicon wafer at a speed of 3000r / min, then fully wash it with deionized water, and dry it with nitrogen gas. Then, the polyacrylic acid solution was spin-coated on the polyacrylamine hydrochloride film at the same rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com