Heat-resistant steel for diesel engine variable cross-section supercharger nozzle assembly and its smelting method

A smelting method and supercharger technology are applied in the field of heat-resistant steel for variable-section supercharger nozzle components of diesel engines and the field of smelting thereof, and can solve the problem of working temperature and harsh working conditions of the components for variable-section supercharger nozzles. problem, to achieve the effect of high temperature and high pressure resistance, dense organization, high heat resistance temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with embodiment.

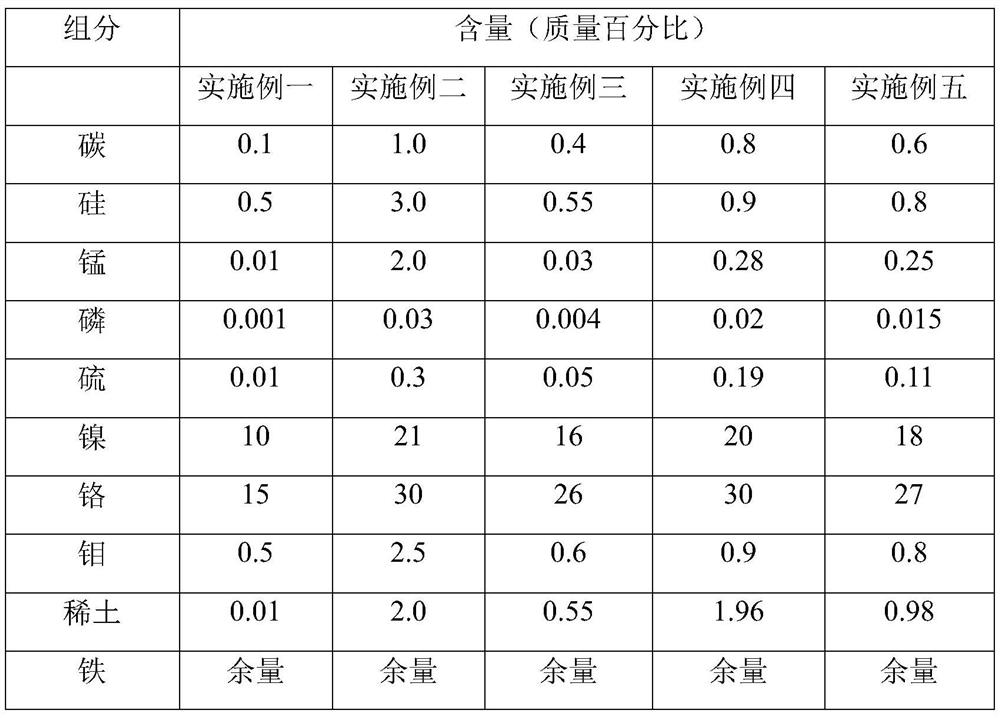

[0026] As shown in Table 1, the embodiment of the present invention provides a heat-resistant steel for a diesel engine variable cross-section supercharger nozzle assembly, comprising: 0.1-1% carbon, 0.5-3% silicon, 0.01-2% manganese %, phosphorus 0.001-0.03%, sulfur 0.01-0.3%, nickel 10-21%, chromium 15-30%, molybdenum 0.5-2.5%, rare earth 0.01-2%, and the balance is iron.

[0027] Further, the heat-resistant steel for diesel engine variable cross-section supercharger nozzle assembly includes, in mass percentage: 0.4-0.8% of carbon, 0.55-0.9% of silicon, 0.03-0.28% of manganese, 0.004-0.02% of phosphorus, and 0.05% of sulfur -0.19%, nickel is 16-20%, chromium is 26-30%, molybdenum is 0.6-0.9%, rare earth is 0.55-1.96%, and the balance is iron.

[0028] Further, the rare earths are lanthanide rare earths.

[0029] Further, the lanthanide rare earth is one or a combination of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com