Novel dielectric barrier discharge plasma exciter

A technology for blocking discharge and plasma, applied in the direction of plasma, electrical components, etc., can solve the problems of damage to the plasma DBD actuator, affecting the surface shape of the model, and prone to tip discharge, etc., to achieve a simple and reliable layout with little impact and interference , the effect of not easy to penetrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

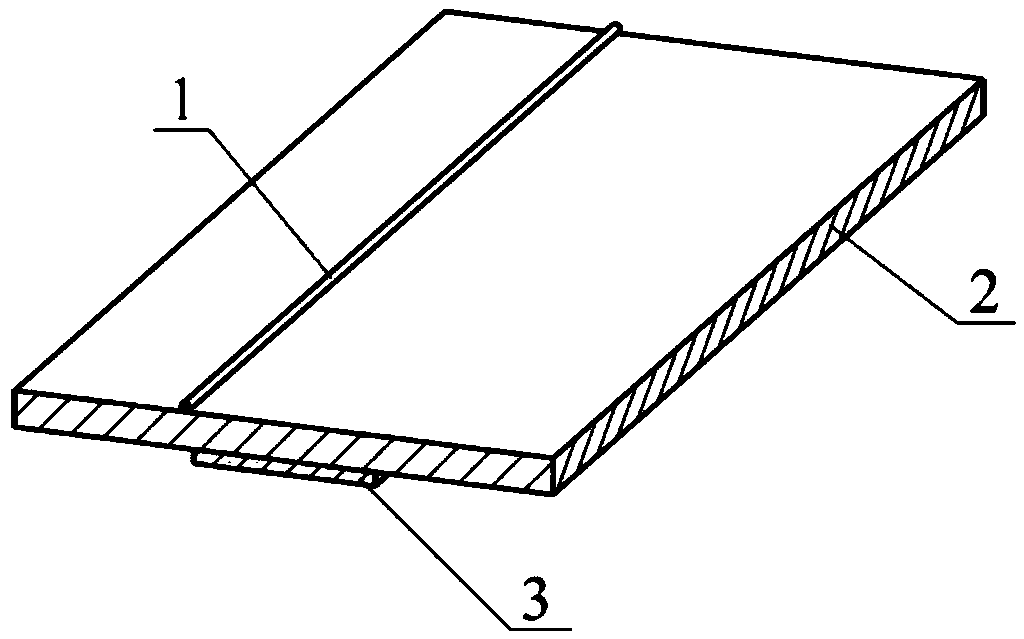

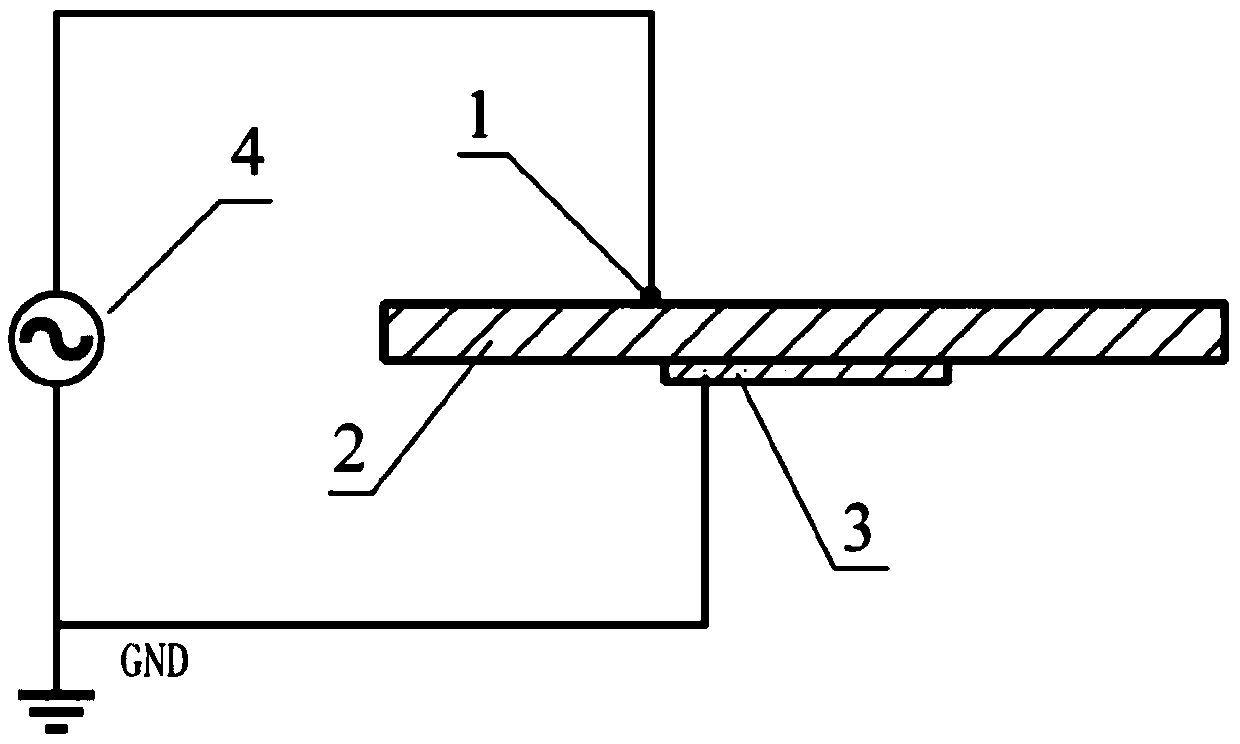

[0023] This embodiment is to make a new type of plasma actuator on a flat plate, wherein, the wire upper electrode 1 adopts a nickel complex alloy wire with a diameter of 0.08mm; the insulating dielectric layer 2 selects a three-layer polyimide film, and its thickness is 0.3 mm. mm; the lower electrode 3 of the metal film is made of copper foil with good electrical conductivity, with a thickness of 0.06 mm and a width of 4 mm. Connect the wire upper electrode 1 and the metal film lower electrode 3 to the high-voltage end and the low-voltage end of the high-frequency high-voltage power supply 4 respectively, and the voltage and frequency of the high-frequency high-voltage power supply 4 are adjustable. The surface of the upper electrode 1 on the metal wire is smooth, without protrusions and burrs, and the discharge is uniform without sharp discharge, and the service life of the plasma exciter is long. There is no additional structure on the entire surface of the plate except th...

Embodiment 2

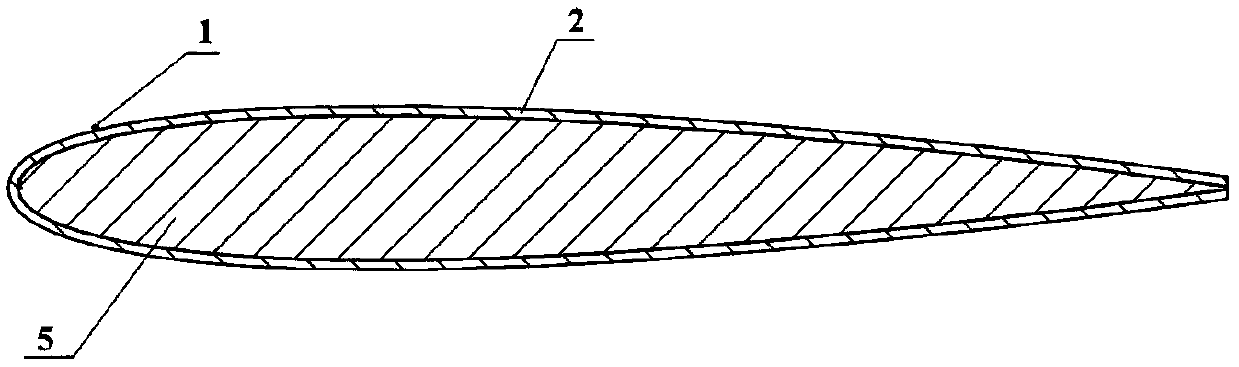

[0025] In this embodiment, the plasma exciter is installed on the metal airfoil, and the upper wire electrode 1 adopts a tungsten wire with a diameter of 0.08mm; the upper wire electrode 1 is kept in a tight state during installation, and is fixed on the The surface of the metal airfoil; the upper electrode of the metal wire and the lower electrode of the metal film are separated by an insulating dielectric layer, and the insulating dielectric layer 2 covers the mounting position on the metal airfoil 5 to form the shape of the metal airfoil. The insulating dielectric layer 2 adopts Three-layer polyimide film; only the wire upper electrode 1 exists on the surface. Since the diameter of the wire upper electrode 1 is very small, it hardly affects the shape of the airfoil, and the impact on the aerodynamic performance is negligible. The upper electrode on the metal wire is kept in a tensioned state during installation, and is fixed by insulating countersunk screws. The arrangement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com