Low-calorie and high-dietary-fiber brown rice nougat and preparation method thereof

A high dietary fiber, low calorie technology, applied in the direction of confectionery, confectionery industry, food science, etc., can solve problems such as single type, and achieve the effect of improving hyperglycemia, reducing blood lipids and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

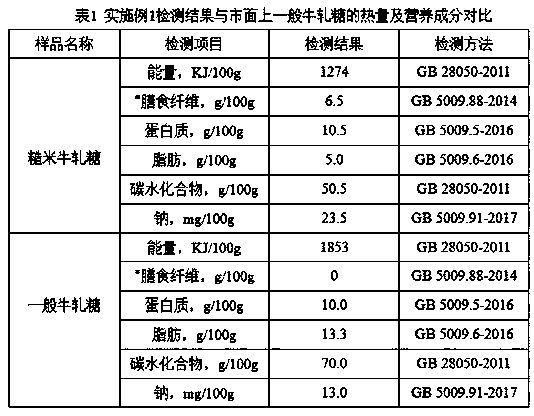

Embodiment 1

[0027] The low-calorie and high-dietary-fiber brown rice nougat of this embodiment consists of the following raw materials in parts by weight: 150 parts of brown rice flakes, 50 parts of yogurt powder, 30 parts of rice bran oil, 10 parts of coconut flour, and maltose prepared from brown rice flakes 5 parts of syrup, 10 parts of erythritol.

[0028] Brown rice crackers are made by steaming and drying brown rice, and puffing at 120°C for 2 minutes.

[0029] Coconut powder is 100% sugar-free coconut powder. Its preparation method is as follows: breaking the coconut shell and peeling to obtain coconut meat, then shredding, drying and pulverizing the coconut meat.

[0030] The maltose syrup prepared from brown rice flakes is crushed from 100 grams of brown rice flakes, and liquefied by adding 0.5 grams of high-temperature-resistant α-amylase (200,000 U / g) and 40 microliters (100,000 U / mL) of glucoamylase for 12 minutes. and 2.5h saccharification, dextrin and oligosaccharides are d...

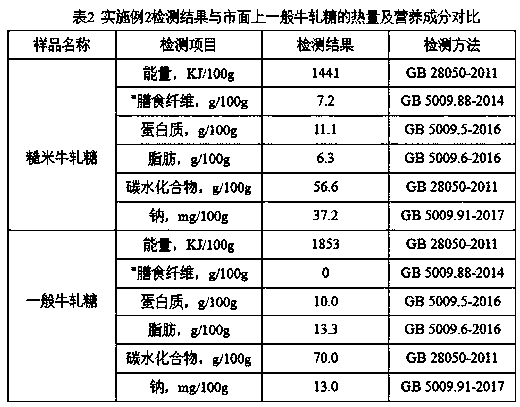

Embodiment 2

[0041] The brown rice nougat with low calorie and high dietary fiber in this embodiment is composed of the following raw materials in parts by weight: 225 parts of brown rice flower, 80 parts of yogurt powder, 40 parts of rice bran oil, 20 parts of coconut powder, and maltose prepared from brown rice flower 8 parts of syrup, 15 parts of erythritol.

[0042] Brown rice crackers are made by steaming and drying brown rice, and puffing at 100°C for 5 minutes.

[0043] Coconut powder is 100% sugar-free coconut powder. Its preparation method is as follows: breaking the coconut shell and peeling to obtain coconut meat, then shredding, drying and pulverizing the coconut meat.

[0044] The maltose syrup prepared from brown rice flakes is crushed from 100 grams of brown rice flakes, and liquefied by adding 0.2 grams of high-temperature resistant α-amylase (200,000 U / g) and 50 microliters (100,000 U / mL) of glucoamylase for 12 minutes and 2.5h saccharification, dextrin and oligosaccharides...

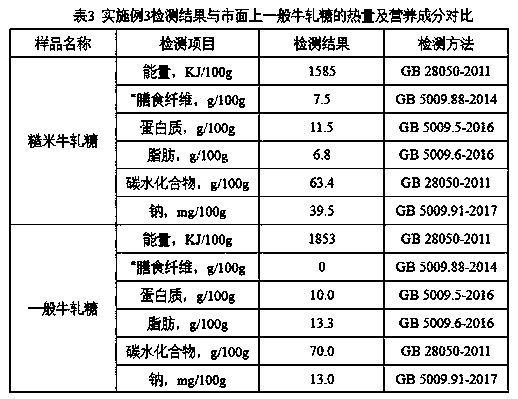

Embodiment 3

[0055] The low-calorie and high-dietary-fiber brown rice nougat of this embodiment consists of the following raw materials in parts by weight: 300 parts of brown rice flakes, 100 parts of yogurt powder, 50 parts of rice bran oil, 40 parts of coconut flour, and maltose prepared from brown rice flakes 10 parts of pulp, 20 parts of erythritol.

[0056] Brown rice crackers are made by steaming and drying brown rice and puffing at 110°C for 3 minutes.

[0057] Coconut powder is 100% sugar-free coconut powder. Its preparation method is as follows: breaking the coconut shell and peeling to obtain coconut meat, then shredding, drying and pulverizing the coconut meat.

[0058] The maltose syrup prepared from brown rice flakes is crushed from 100 grams of brown rice flakes, and liquefied by adding 0.3 grams of high-temperature-resistant α-amylase (200,000 U / g) and 45 microliters (100,000 U / mL) of glucoamylase for 12 minutes. and 2.5h saccharification, dextrin and oligosaccharides were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enzyme activity | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com