Method for purifying and deodorizing tail gas generated in production process of fermented cordyceps powder

A technology for fermenting Cordyceps fungus powder and production process, applied in chemical instruments and methods, separation methods, gas treatment, etc. The effect of improving spray efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

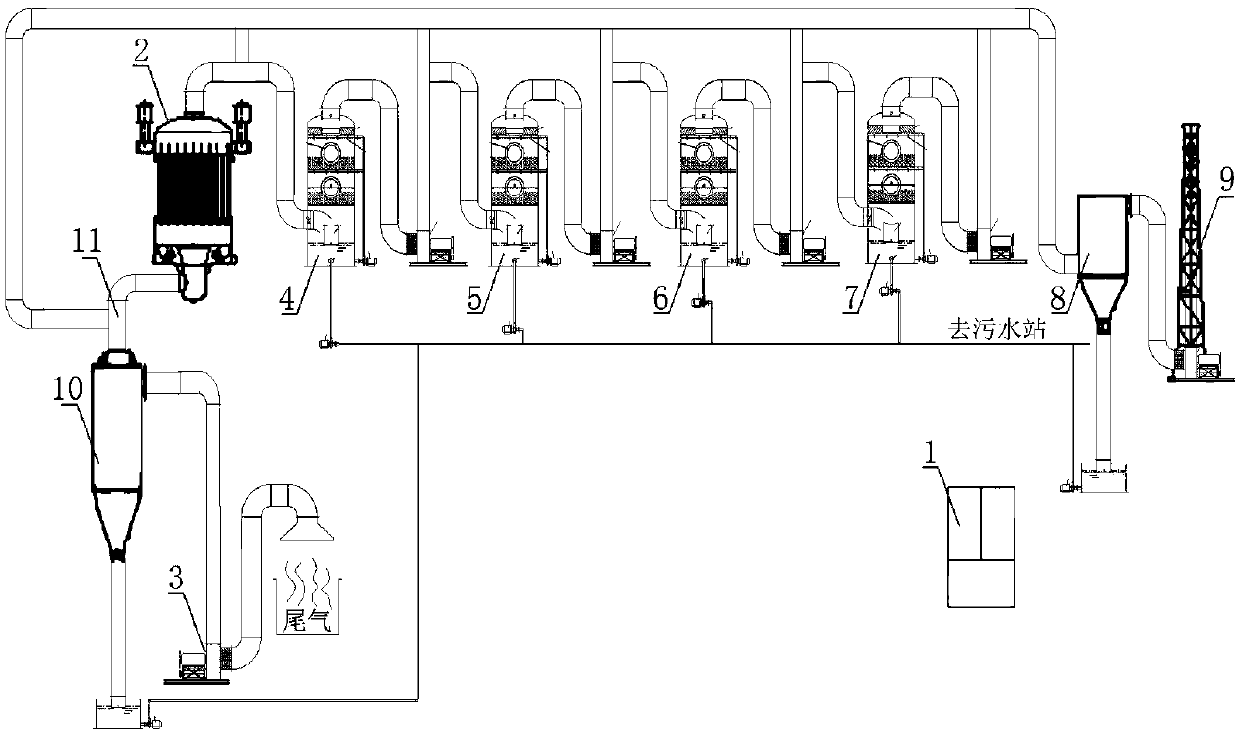

Image

Examples

Embodiment 1

[0030] 1) Set the start-up temperature of the heat exchange system at 40°C. The spray liquids of the spray towers at all levels are sodium hypochlorite, sodium hydroxide, water, and sodium hydroxide in sequence; the concentration ranges of the spray liquids are 4%, 2%, and 100% in sequence. %, 6%; the initial spray speed is set to 0.

[0031] 2) After the exhaust gas from the fermentation tank produced in the production process of the fermented Cordyceps powder is separated by the cyclone separator, the non-condensable gas enters the exhaust gas monitoring buffer room equipped with temperature and gas concentration monitoring sensors. According to the monitoring data of the monitoring sensors, the solenoid valve is automatically controlled And the blower selectively passes the non-condensable gas through the heat exchange system, the first-level spray tower system, the second-level spray tower system, the third-level spray tower system, and the fourth-level spray tower system. ...

Embodiment 2

[0034] 1) Set the start-up temperature of the heat exchange system at 40°C, and the spray liquids of the spray towers at all levels are sodium hypochlorite, sodium hydroxide, water, and sodium hydroxide in sequence; the concentration ranges of the spray liquids are 2%, 2%, and 100 %, 2%; the initial spray speed is set to 0.

[0035] 2) After the waste gas from the extraction post space generated during the production process of fermented Cordyceps powder is separated by the cyclone separator, the non-condensable gas enters the waste gas monitoring buffer room equipped with temperature and gas concentration monitoring sensors. According to the monitoring data of the monitoring sensors, the self-control solenoid valve and The blower selectively passes the non-condensable gas through the heat exchange system, the first-level spray tower system, the second-level spray tower system, the third-level spray tower system, and the fourth-level spray tower system. After the mist is remov...

Embodiment 3

[0038] 1) Set the start-up temperature of the heat exchange system at 40°C. The spray liquids of the spray towers at all levels are sodium hypochlorite, sodium hydroxide, water, and sodium hydroxide in sequence; the concentration ranges of the spray liquids are 7%, 2%, and 100% in sequence. %, 10%; the initial spray speed is set to 0.

[0039] 2) After the dry waste gas from the production process of fermented Cordyceps powder is separated by the cyclone separator, the non-condensable gas enters the waste gas monitoring buffer room equipped with temperature and gas concentration monitoring sensors. According to the monitoring data of the monitoring sensors, the self-control solenoid valve and blower will The non-condensable gas selectively passes through the heat exchange system, the first-level spray tower system, the second-level spray tower system, the third-level spray tower system, and the fourth-level spray tower system. Evacuate through the chimney after removing the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com