Method for preparing UiO-66 based on benzoic acid regulation and chloroform activation and adsorption application

A uio-66, benzoic acid technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of affecting the adsorption of macromolecular dyes, affecting hydrophobicity, low surface area, etc., and achieving low cost , convenient for mass production, high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

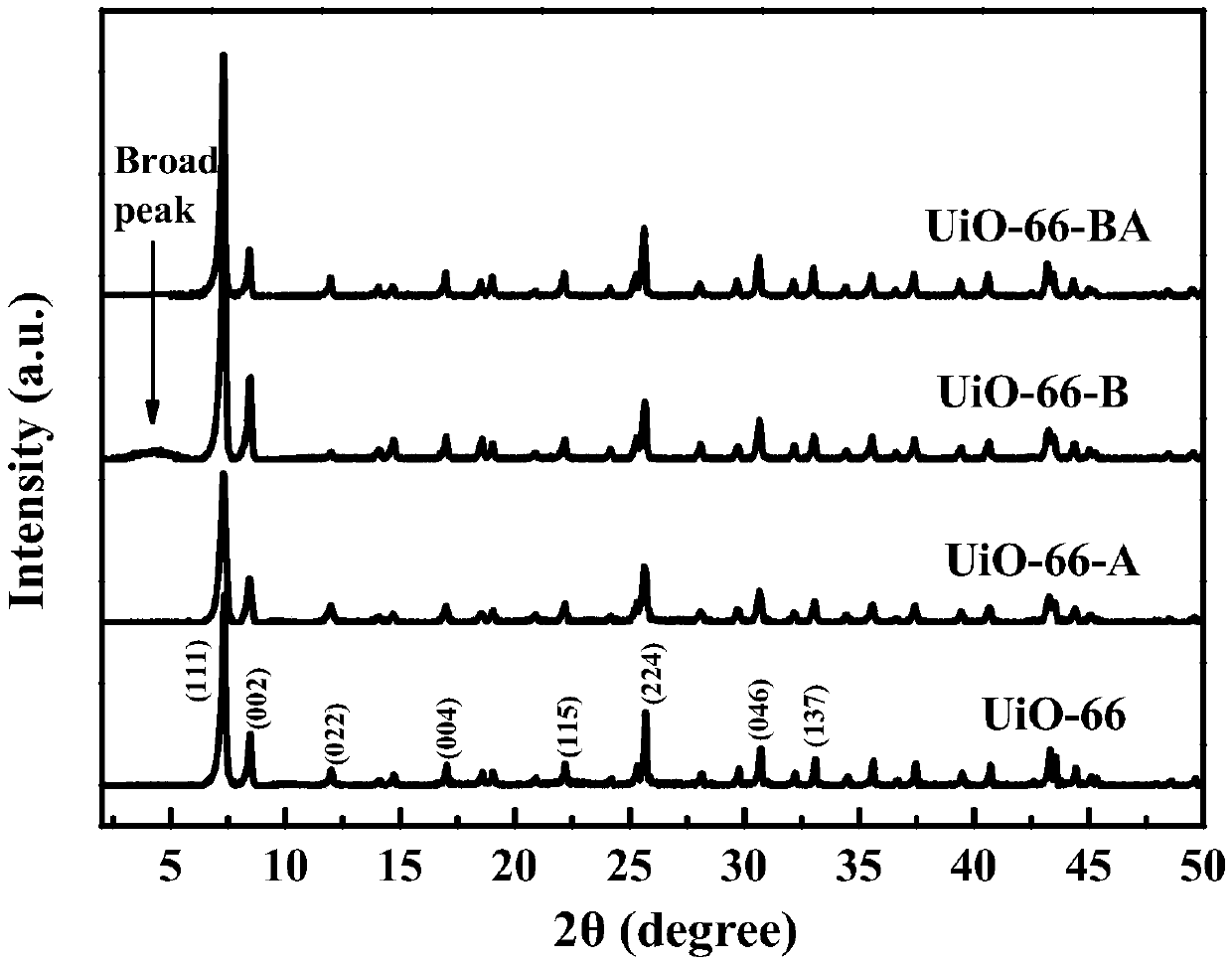

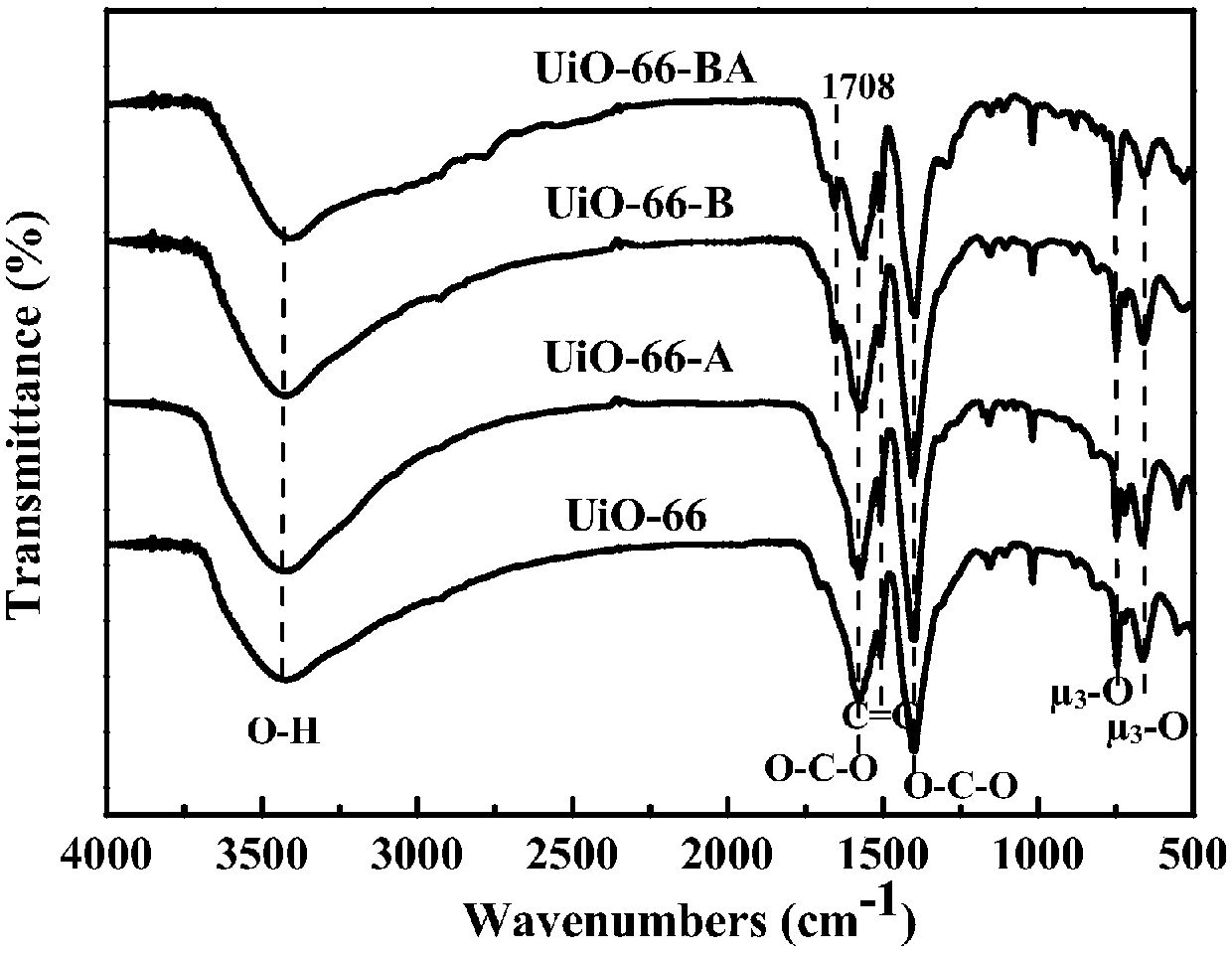

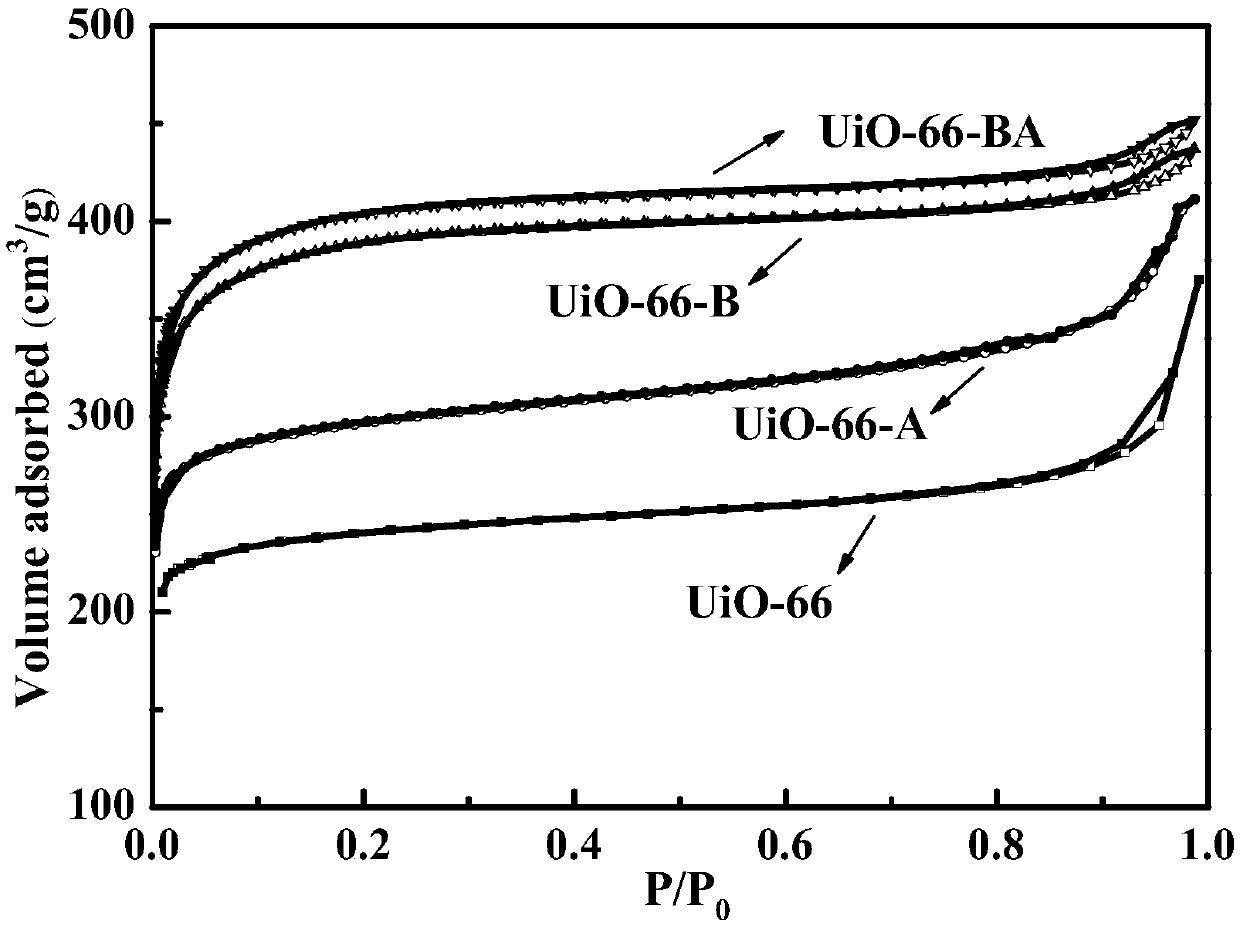

[0024] UiO-66-BA was synthesized by solvothermal method. Specifically, proceed as follows:

[0025] (1) 0.386g (1.67mmol) ZrCl 4 , 0.276g (1.67mmol) H 2 BDC and 6.118g (50.1mmol) of benzoic acid were dissolved in 50ml of DMF solution, stirred evenly and then poured into a stainless steel autoclave lined with polytetrafluoroethylene. where ZrCl 4 :H 2 The molar ratio of BDC:benzoic acid is 1:1:30.

[0026] (2) Then the reaction kettle was heated at 120° C. for 24 hours in a blast drying oven. After the reactor was cooled to room temperature, it was centrifuged to obtain white crystals.

[0027] (3) The obtained white crystals were washed three times with DMF and methanol, then immersed in 100 ml of methanol solution and treated in a reaction kettle at 100° C. for 12 hours, filtered after treatment, washed the filter cake, and dried to obtain a powder.

[0028] (4) The above powder was immersed in chloroform for 5 days, suction filtered, and the obtained sample was centri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com