Method for preparing anti-freeze environment-friendly brick

An environmentally friendly brick and a technology for preparation steps, which are applied in ceramic products, applications, household appliances, etc., can solve problems such as affecting the service life of environmentally friendly bricks, not being able to use them in alpine regions, and destroying the structure of environmentally friendly bricks, so as to promote stability and increase mechanical strength , Improve the effect of frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

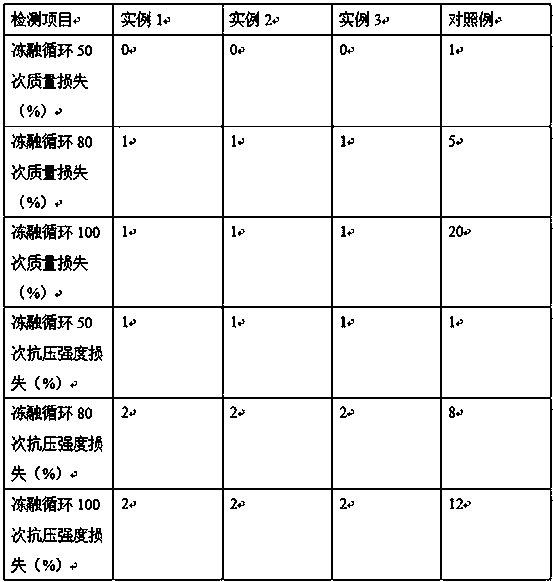

Examples

example 1

[0023] According to the mass ratio of 1:20, the waste goose feather and the hydrochloric acid with a mass fraction of 30% were mixed, soaked at 60°C for 3 hours, and the filter residue was obtained by filtering and separating. The filter residue and the sodium bisulfite solution with a mass fraction of 30% were After mixing at 1:20, continue soaking at 60°C for 3 hours, filter and separate to obtain a filter cake; mix the filter cake with 15% sodium hydroxide solution at a mass ratio of 1:10, and put it into a microwave oscillator. At 70°C, react with microwave oscillation at 200W power for 1 hour. After the reaction, filter and remove the reaction residue to obtain the reaction filtrate; put the reaction filtrate into a beaker, and adjust the pH of the above reaction filtrate to neutral with hydrochloric acid with a concentration of 1mol / L. Obtain the pretreatment filtrate, continue to add the concentration of pretreatment filtrate mass 10% in the beaker and be 1mol / L potassiu...

example 2

[0025]According to the mass ratio of 1:20, the waste goose feather and the hydrochloric acid with a mass fraction of 30% were mixed, soaked at 65°C for 3 hours, and the filter residue was obtained by filtering and separating. The filter residue and the sodium bisulfite solution with a mass fraction of 30% were After mixing at 1:20, continue soaking at 65°C for 3 hours, filter and separate to obtain a filter cake; mix the filter cake with 15% sodium hydroxide solution at a mass ratio of 1:10, and put it into a microwave oscillator. At 75°C, react with microwave oscillation at a power of 250W for 2 hours. After the reaction, filter and remove the reaction residue to obtain the reaction filtrate; put the reaction filtrate into a beaker, and adjust the pH of the above reaction filtrate to neutral with hydrochloric acid with a concentration of 1mol / L. Obtain the pretreatment filtrate, continue to add the concentration of pretreatment filtrate mass 10% in the beaker and be 1mol / L pot...

example 3

[0027] According to the mass ratio of 1:20, mix waste goose feathers with hydrochloric acid with a mass fraction of 30%, soak at 70°C for 4 hours, and filter and separate to obtain a filter residue. After mixing at 1:20, continue soaking at 70°C for 4 hours, filter and separate to obtain the filter cake; mix the filter cake and sodium hydroxide solution with a mass fraction of 15% at a mass ratio of 1:10 and put it into a microwave oscillator. At 80°C, react with microwave oscillation at a power of 300W for 2 hours. After the reaction, filter and separate and remove the reaction filter residue to obtain the reaction filtrate; put the reaction filtrate into a beaker, and adjust the pH of the above reaction filtrate to neutral with hydrochloric acid with a concentration of 1mol / L. Obtain pretreatment filtrate, continue to add the concentration of pretreatment filtrate mass 10% in the beaker and be 1mol / L potassium chloride solution, stir and react at 70 ℃ for 30min, obtain reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com