Metal complex, organic electroluminescent material, organic electroluminescent device

A metal complex, metal technology, applied in the direction of luminescent materials, electric solid devices, electrical components, etc., can solve the problems of reducing the quantum yield of the red light system, aggravating the quenching of phosphors, and low external quantum efficiency, etc., and achieves easy sublimation. Purification, improved luminous efficiency, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

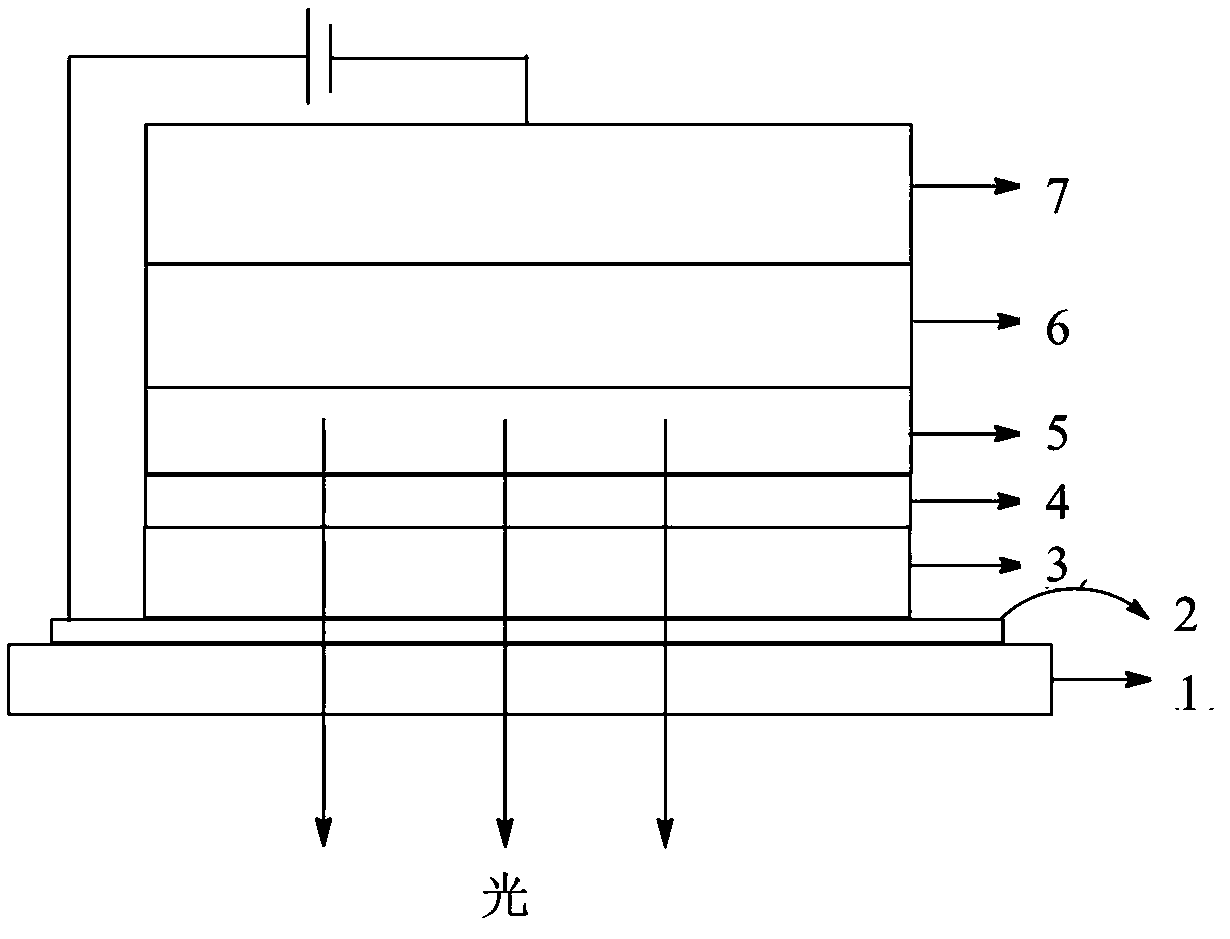

[0192] As the preparation method of the organic electroluminescent device of the present invention, the following preparation methods can be listed, but not limited thereto, and those skilled in the art can make various changes according to the technical common knowledge in the field. The aforementioned preparation method comprises the following steps:

[0193] Cleaning process: use cleaning agent, deionized water, organic solvent, etc. to clean the glass substrate with ITO;

[0194] The step of forming a hole injection layer: a hole injection layer forming material containing the metal complex of the present invention is vapor-deposited on the aforementioned anode layer by vacuum evaporation, thereby forming holes containing the metal complex of the present invention on the aforementioned substrate. hole injection layer;

[0195] The process of forming a hole transport layer: forming a hole transport layer on the aforementioned hole injection layer by vacuum evaporation;

...

Embodiment 1

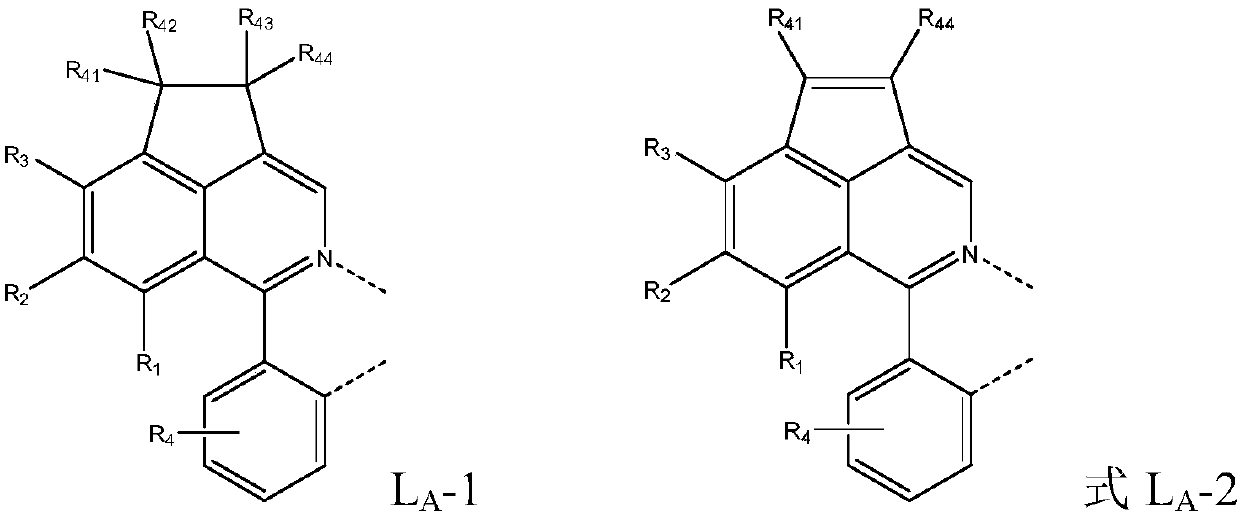

[0207] Preparation of LA314:

[0208] The preparation method of ligand LA314 comprises the following steps:

[0209] Step 1: Preparation of Compound Int.-1

[0210]

[0211] 37.5g (109.4mmol) of methoxymethyltriphenylphosphorous chloride was dispersed in 500mL of anhydrous THF, under the protection of nitrogen, the temperature was lowered to -78°C with liquid nitrogen, and 12.3g (109.4mmol) of Potassium tert-butoxide, raised to room temperature and stirred for 30 minutes, then cooled to -78°C again, added dropwise 19.5g (91.2mmol) of 7-bromo-1-indanone, after the addition, kept stirring for 1 hour, Rise to room temperature and stir the reaction overnight, add 150mL of saturated ammonium chloride aqueous solution, extract with ethyl acetate, dry the organic phase with anhydrous sodium sulfate, filter, concentrate under reduced pressure to dryness, separate and purify with a silica gel column, and obtain 16.2g of Compound Int.-1 as a colorless oil.

[0212] The second step...

Embodiment 2

[0222] The preparation of compounds LA1~LA313, LA315~LA563, LA787~LA1912, referring to the preparation method of Example 1, replaced the 7-bromo-1-indanone with different substituents in the first step of Example 1. Bromo-1-indanone, replace bromobenzene or bromobenzene with different substituents with 3,5-dimethylbromobenzene in the third step of Example 1 to prepare LA1~LA313 and LA315 in the ligand LA ~LA563 and LA787~LA1912.

PUM

| Property | Measurement | Unit |

|---|---|---|

| external quantum efficiency | aaaaa | aaaaa |

| external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com