Silane cross-linked flame-retardant polyvinyl chloride cable material and preparation method thereof

A flame-retardant polyvinyl chloride and silane cross-linking technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of poor color stability and easy discoloration of products, and achieve good mechanical strength and color stability. , the effect of high gelation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

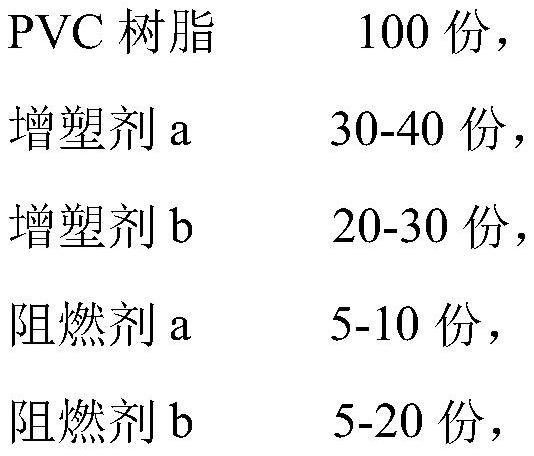

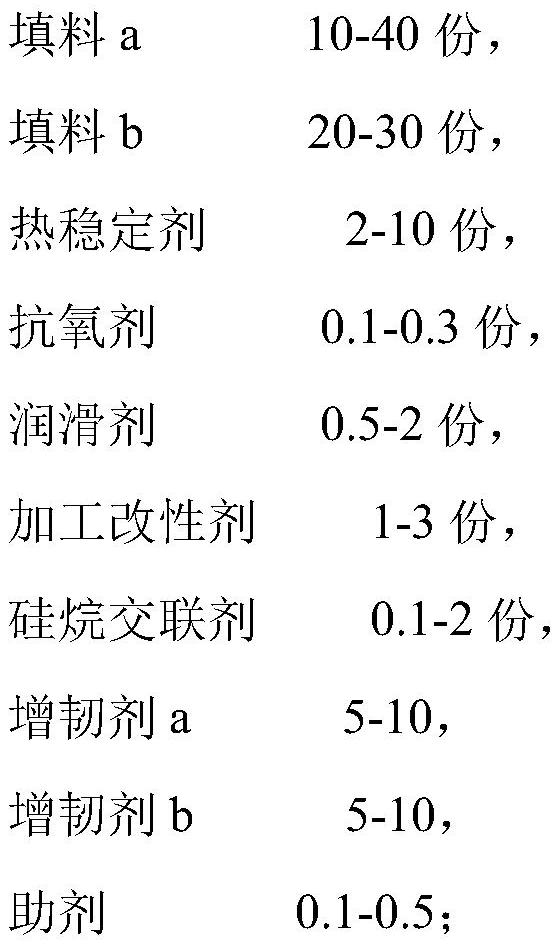

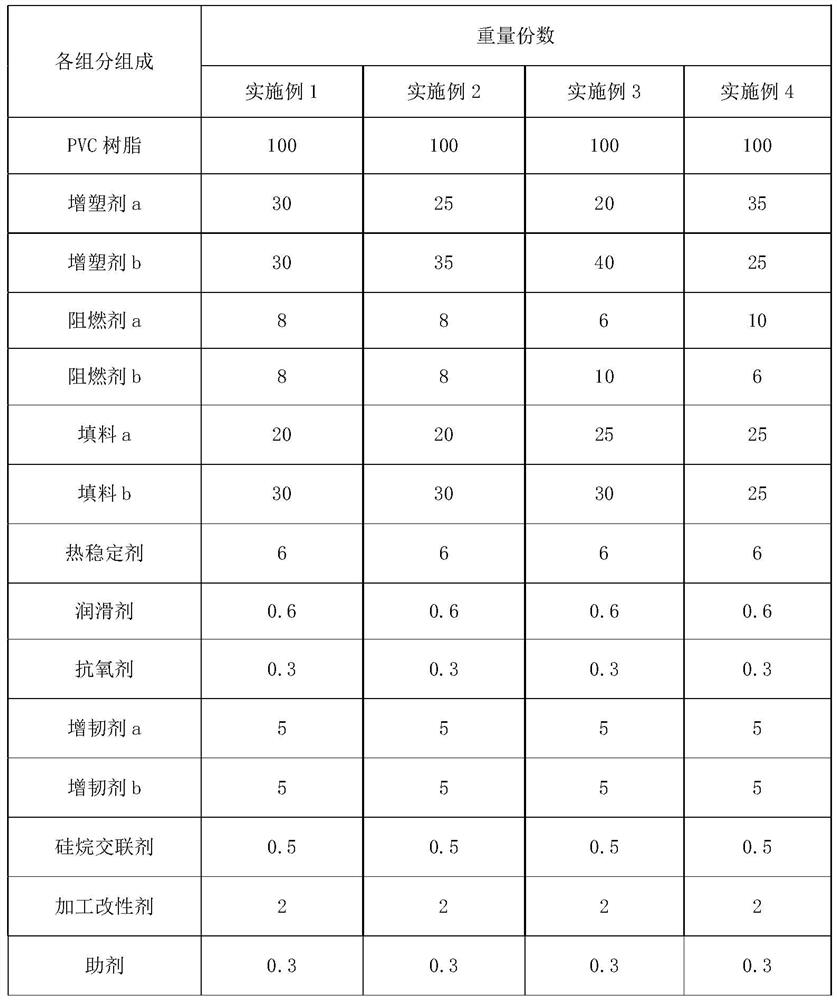

[0028] Examples 1-4: A silane crosslinked flame-retardant polyvinyl chloride cable material and its preparation method

[0029] Silane crosslinked flame-retardant polyvinyl chloride cable material, its raw material formula (unit: parts by weight) is shown in Table 1:

[0030] Table 1 Silane cross-linked flame-retardant PVC cable material

[0031]

[0032] The name of each component raw material used in the embodiment of table 2:

[0033]

[0034]

[0035] The production process is carried out in one step according to the following steps: preparation of raw and auxiliary materials-measurement and weighing according to the formula ratio-high-speed kneading-extrusion mixing and plasticization by twin-screw extruder unit-single-screw granulation-cooling and sieving-guarantee. The kneading process uses a high-speed kneader to raise the temperature of the raw and auxiliary materials to 130-140°C under high-speed friction, and obtain sufficient mixing and pre-plasticization; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com