Method for preparing photoelectrolytic nonwoven cloth through electrostatic spinning

A technology of electrospinning and non-woven fabrics, applied in the field of fiber materials, can solve the problems of adsorption of pollutants, easy breeding of bacteria, restrictions, etc., and achieve the effect of reducing the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing photocatalytic non-woven fabrics by electrostatic spinning includes the following preparation steps:

[0020] S1, 2 parts of aniline, 1 part of nano titanium dioxide and 50 parts of acrylic fiber are dissolved in dimethylacetamide at 20°C to obtain a mixed solution;

[0021] S2. Use the electrostatic spinning method to spin the mixed solution to prepare a non-woven fabric. The non-woven fabric is soaked in a hydrochloric acid solution with a concentration of 1 mole per liter at 0~5°C for 24 hours, washed with water, and dried to obtain photocatalysis Non-woven fabric.

Embodiment 2

[0023] A method for preparing photocatalytic non-woven fabrics by electrostatic spinning includes the following preparation steps:

[0024] S1, 6 parts of aniline, 3 parts of nano titanium dioxide and 98 parts of polyester are dissolved in dimethylformamide at 100°C to obtain a mixed solution;

[0025] S2. Use the electrostatic spinning method to spin the mixed solution to prepare a non-woven fabric. The non-woven fabric is soaked in a hydrochloric acid solution with a concentration of 1 mole per liter at 0~5°C for 24 hours, washed with water, and dried to obtain photocatalysis Non-woven fabric.

Embodiment 3

[0027] A method for preparing photocatalytic non-woven fabrics by electrostatic spinning includes the following preparation steps:

[0028] S1, 4 parts of aniline, 2 parts of nano titanium dioxide and 70 parts of polypropylene are dissolved in medium dimethyl sulfoxide at 50°C to obtain a mixed solution;

[0029] S2. Use the electrostatic spinning method to spin the mixed solution to prepare a non-woven fabric. The non-woven fabric is soaked in a hydrochloric acid solution with a concentration of 1 mole per liter at 0~5°C for 24 hours, washed with water, and dried to obtain photocatalysis Non-woven fabric.

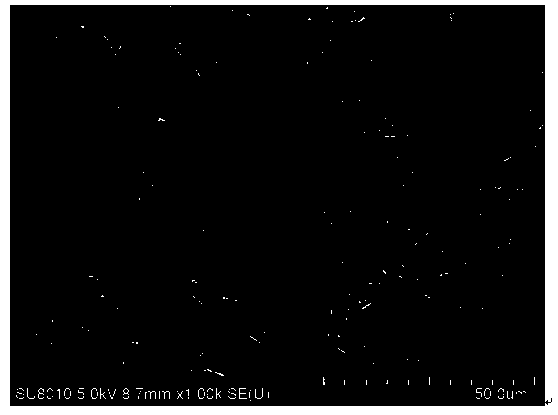

[0030] The scanning electron microscope image of the photocatalytic non-woven fabric prepared by electrospinning in Example 1 is as follows figure 1 As shown, it can be seen that a non-woven fabric with densely interlaced fibers is prepared by the electrostatic spinning method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com