Novel filter paper for conventional chemical detection of flue gas and preparation method of novel filter paper

A flue gas and filter paper technology, applied in chemical instruments and methods, filter paper, separation methods, etc., can solve problems such as polluting the working environment and damaging the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

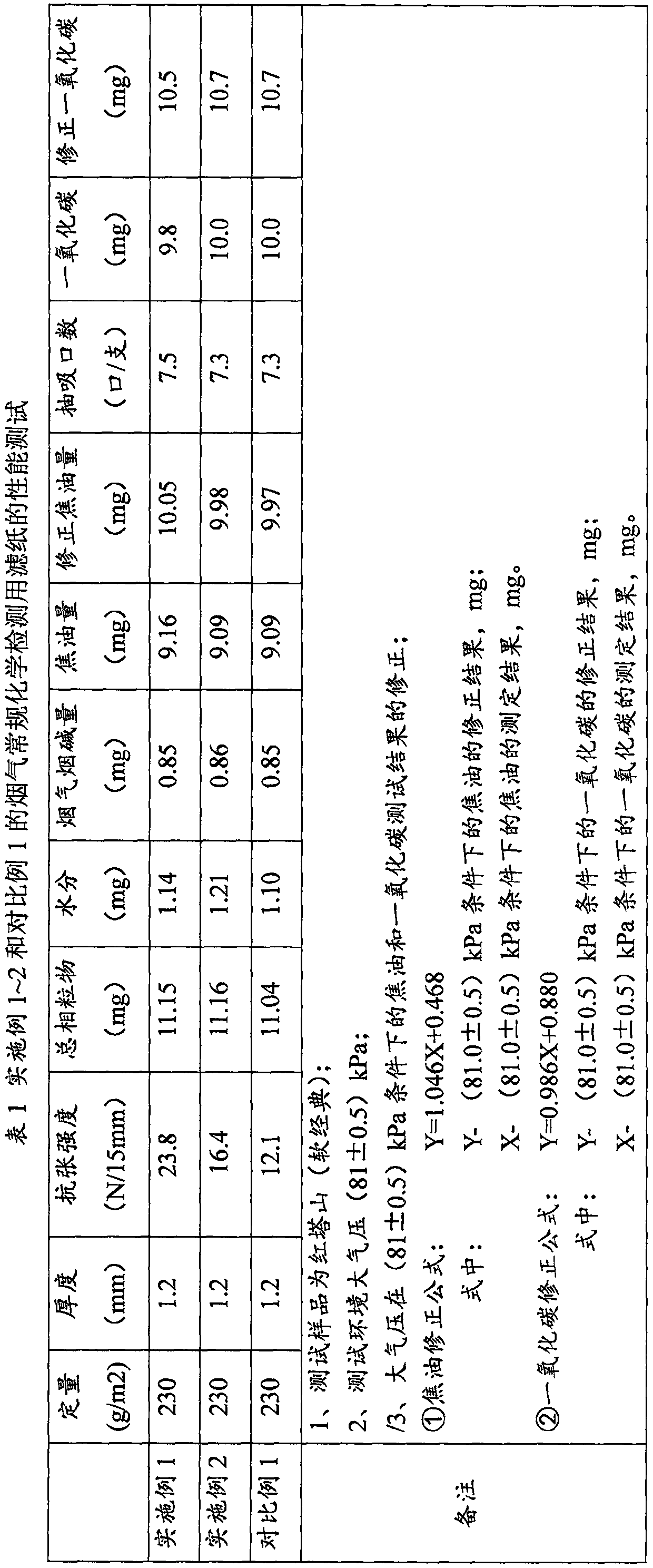

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing glass fiber filter paper for routine chemical detection of flue gas according to the above technical scheme, which includes the following steps:

[0034] Mixing synthetic chemical fiber with water for disintegration treatment to obtain synthetic chemical fiber slurry;

[0035] Mixing glass fiber with water for disintegration treatment to obtain glass fiber slurry;

[0036] Mixing the synthetic chemical fiber slurry, glass fiber slurry, adhesive fiber latex, wet strength agent and dispersant to obtain a mixed slurry;

[0037] The mixed slurry is subjected to wet molding to obtain filter paper for routine chemical detection of flue gas.

[0038] In the invention, the synthetic chemical fiber is mixed with water for disintegration treatment to obtain the synthetic chemical fiber slurry. In the present invention, the concentration of the synthetic chemical fiber slurry is preferably 2 to 3.5 wt%. The present invention has n...

Embodiment 1

[0046] The raw materials for preparing filter paper for routine chemical detection of flue gas include synthetic chemical fiber, glass fiber, latex for bonding fiber, wet strength agent, dispersant and water; among them, based on the weight fraction of dry fiber, synthetic chemical fiber (polyester fiber, Skin-core structure, diameter 2dex, length 6mm, skin softening temperature 110℃) the addition amount is 50 parts, the addition amount of glass fiber (1#, diameter 15.0μm, length is 3mm) is 25 parts, glass fiber (2#, The addition amount of 1.5μm in diameter and 6mm in length) is 15 parts, the addition amount of glass fiber (3#, 0.8μm in diameter and 6mm in length) is 10 parts, and the latex for bonding fiber (vinyl acetate, Tg=5℃) ) The addition amount is 6.0% of the weight of the bone dry fiber, the wet strength agent (polyamide epichlorohydrin resin) is 0.1% of the weight of the bone dry fiber, and the addition amount of the dispersant (polyethylene oxide) is 0.7 of the weight...

Embodiment 2

[0052] The raw materials for preparing filter paper for routine chemical detection of flue gas include synthetic chemical fiber, glass fiber, latex for bonding fiber, wet strength agent, dispersant and water; among them, based on the weight fraction of dry fiber, synthetic chemical fiber (polypropylene fiber , Side-by-side structure, diameter 1.5dex, length 3mm) add 20 parts, glass fiber (1#, diameter 20.0μm, length 3mm) add 50 parts, glass fiber (2#, diameter 2μm, length is The addition amount of 10mm) is 30 parts, the addition amount of the adhesive fiber latex (acrylic resin, Tg=45℃) is 10.0% of the weight of the bone-dry fiber, and the wet strength agent (polyamide epichlorohydrin resin) is the bone-dry fiber 0.3% by weight, and the added amount of dispersant (polyethylene oxide) is 0.5% by weight of the bone dry fiber.

[0053] The method for preparing filter paper for routine chemical detection of flue gas includes the following steps:

[0054] Mix glass fiber with water for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap