UV&LED solidified aqueous co-polymerization fluorescent nail polish gel

A technology of UV&LED and nail polish, applied in cosmetics, manicure, cosmetic preparations, etc., can solve the problems of human injury, floating color, poor compatibility, etc., achieve short curing and film forming time, solve unsafe factors, durable Good abrasiveness and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

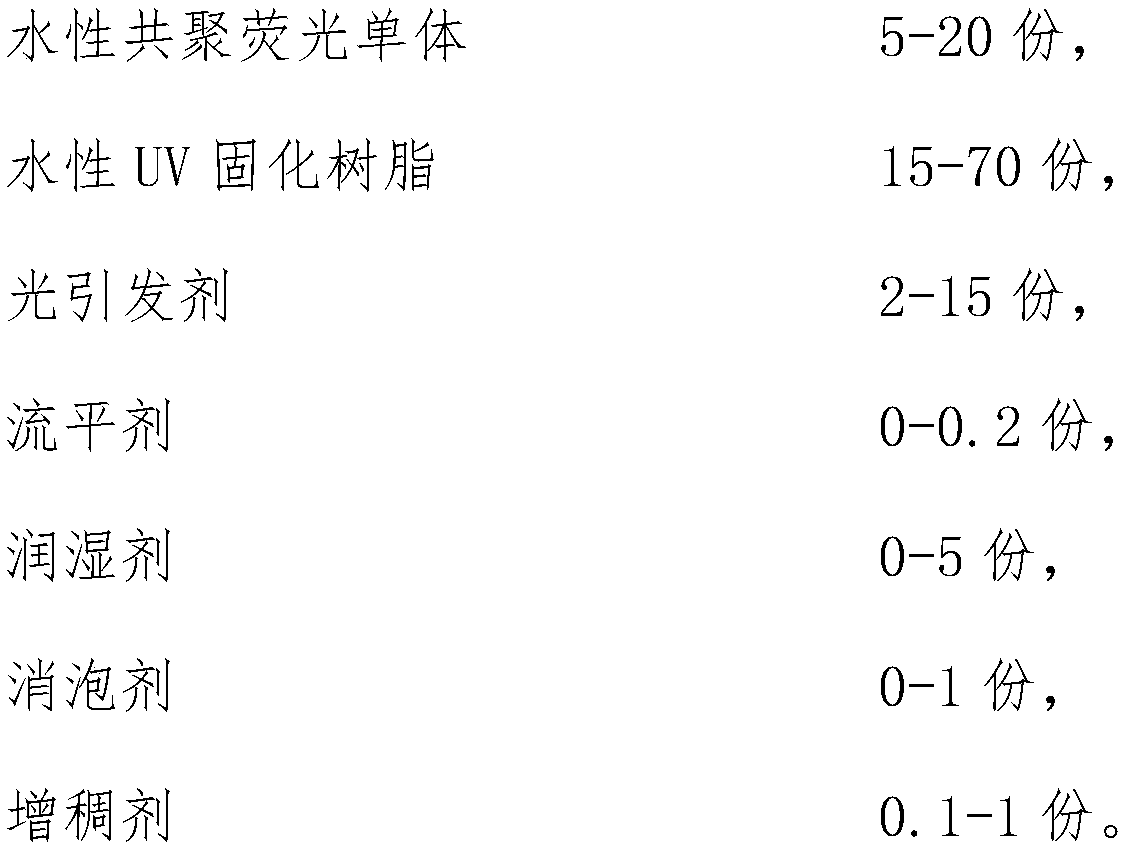

[0024] 12 parts of water-based copolymerized fluorescent monomer, 65 parts of water-based UV curable resin, 6 parts of photoinitiator, 0.5 part of leveling agent, 0.5 part of wetting agent, 0.1 part of defoamer, and 0.3 part of thickener.

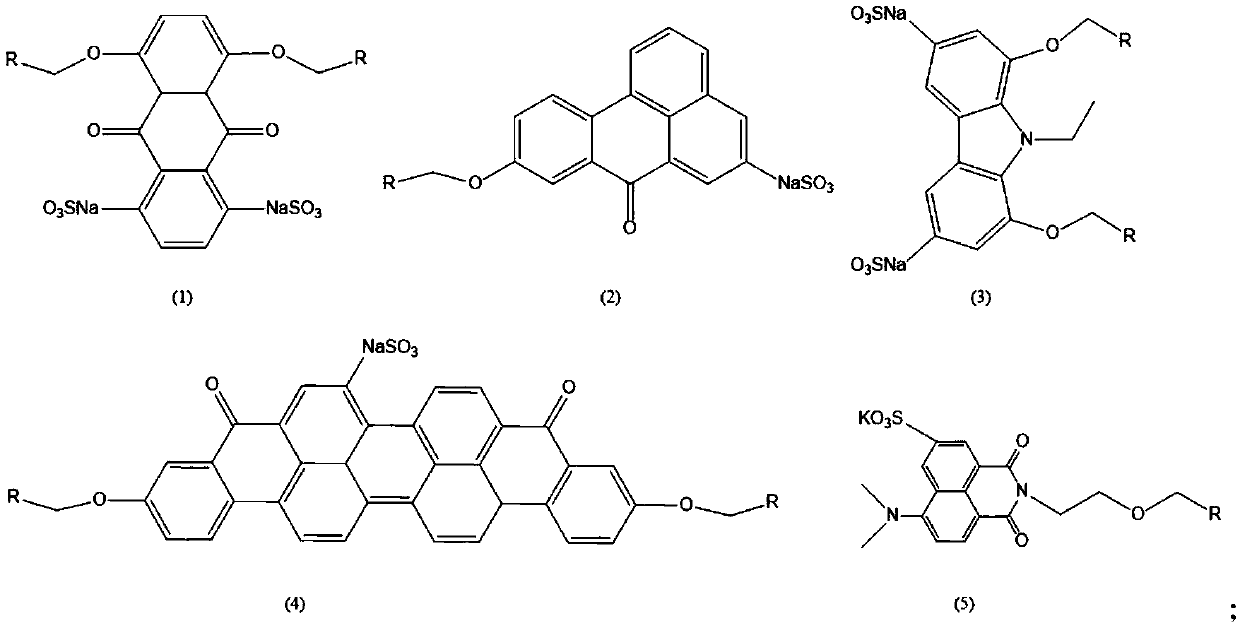

[0025] The structural formula of the aqueous copolymerized fluorescent monomer is;

[0026]

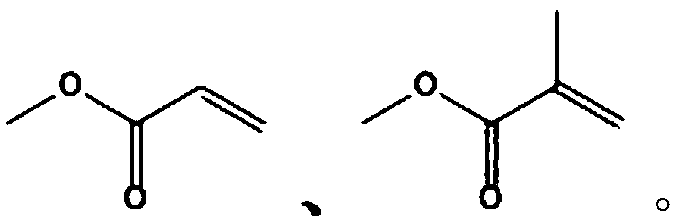

[0027] The structural formula of R in the formula is:

[0028] UV curable water-based urethane acrylate is a mixture of WUV-48 water-based UV urethane acrylate of Guangzhou Dijing Chemical Technology Co., Ltd. and YS-8806 modified urethane acrylate of Changzhou Yurong Chemical Co., Ltd. in a mass ratio of 2:1;

[0029] The photoinitiator is a mixture of Irgacure 2959 and Irgacure 1173 in a mass ratio of 2:1;

[0030] The leveling agent is BYK-348;

[0031] The wetting agent is Tego Glide 270;

[0032] The defoamer is Tego Glide 902 W;

[0033] The thickener is a mixture of PUR-80 and PUR-85 in a mass ratio of 2:1.

[0034] In this embodim...

Embodiment 2

[0041] 10 parts of water-based copolymerized fluorescent monomer, 60 parts of water-based UV curable resin, 6.7 parts of photoinitiator, 0.5 part of leveling agent, 0.7 part of wetting agent, 0.1 part of defoamer, and 0.4 part of thickener.

[0042] The structural formula of the aqueous copolymerized fluorescent monomer is;

[0043]

[0044] The structural formula of R in the formula is:

[0045] UV-curable water-based polyurethane acrylate is a mixture of WUV-48 water-based UV polyurethane acrylate of Guangzhou Dijing Chemical Technology Co., Ltd. and RA7016 of Mitsui Chemicals in a mass ratio of 2:3;

[0046] The photoinitiator is a mixture of Irgacure TPO and Irgacure 1173 in a mass ratio of 3:2;

[0047] The leveling agent is BYK-348;

[0048] The wetting agent is a mixture of NP-100 and Tego Glide 270 in a mass ratio of 2:3;

[0049] The defoamer is Tego Glide 902 W;

[0050] The thickener is a mixture of PUR-64 and PUR-80 in a mass ratio of 3:2.

[0051] In the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com