Method for preparing up-converting phosphor developing coating on surface of magnesium alloy

A magnesium alloy and fluorescence technology, applied in surface reaction electrolytic coatings, coatings, electrolytic coatings, etc., can solve the problems of restricting the biological activity of magnesium alloys and magnesium alloys and poor X-ray development, so as to solve corrosion problems and avoid radiation. Damage, eliminate residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

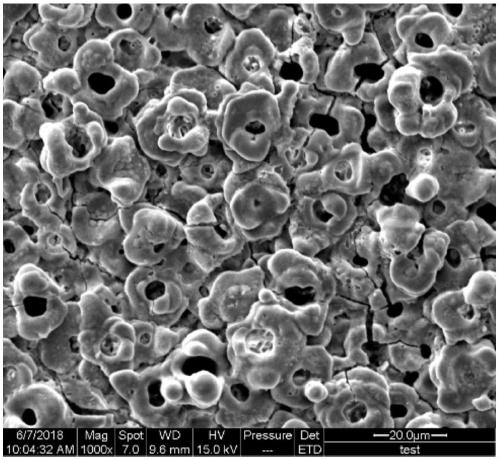

[0032] Specific Embodiment 1: This embodiment is a method for preparing an up-conversion fluorescent developing coating on the surface of a magnesium alloy, which is completed in the following steps:

[0033] 1. Magnesium alloy pretreatment: Use 180#SiC sandpaper, 1000#SiC sandpaper and 2000#SiC sandpaper to polish the magnesium alloy in sequence to obtain a bright magnesium alloy;

[0034] 2. Ultrasonic degreasing: immerse the bright magnesium alloy in acetone, and then ultrasonically treat it for 5min-10min at an ultrasonic power of 800W-1000W to obtain the magnesium alloy after ultrasonic treatment; rinse the magnesium alloy after ultrasonic treatment with distilled water 3 to 5 times, and then use a hair dryer to dry to obtain a degreased magnesium alloy;

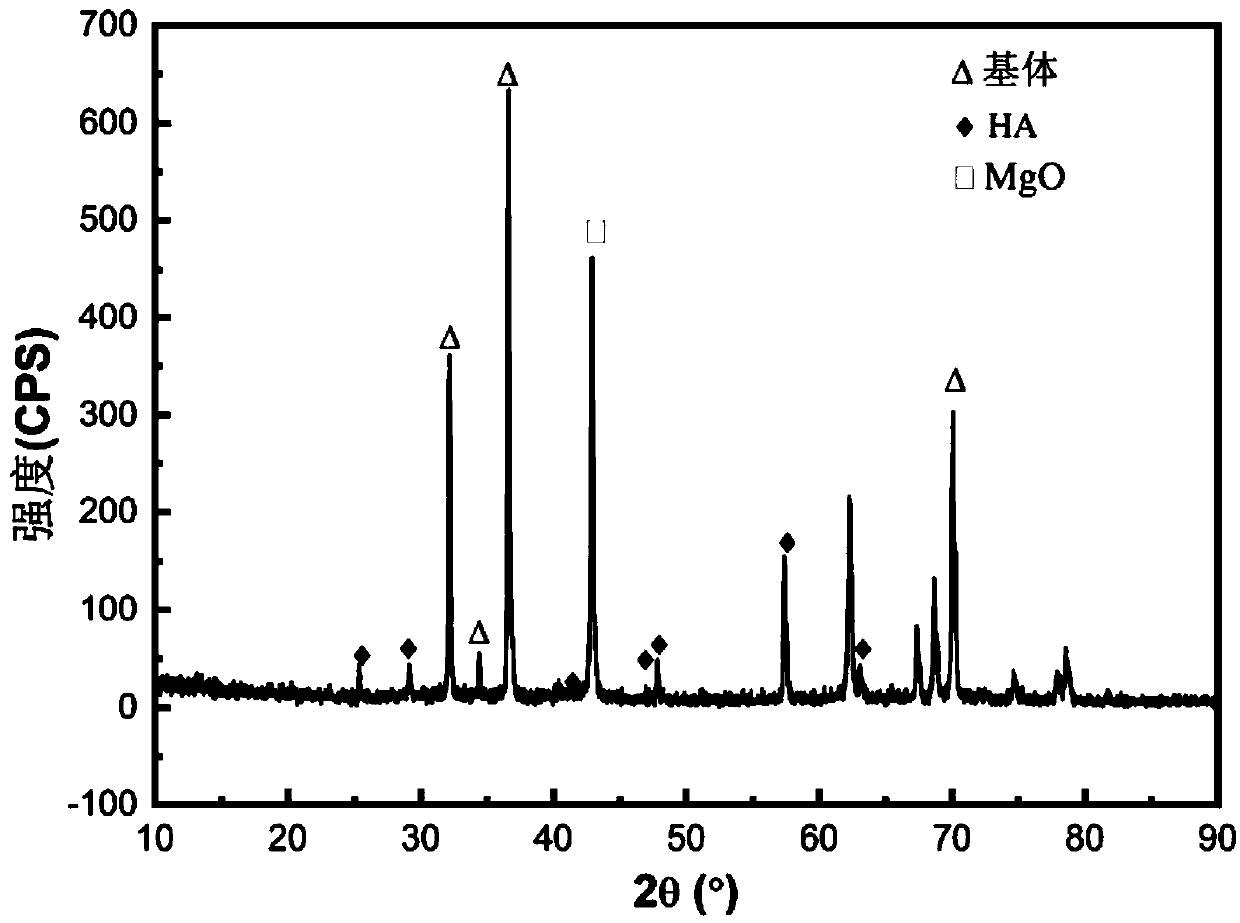

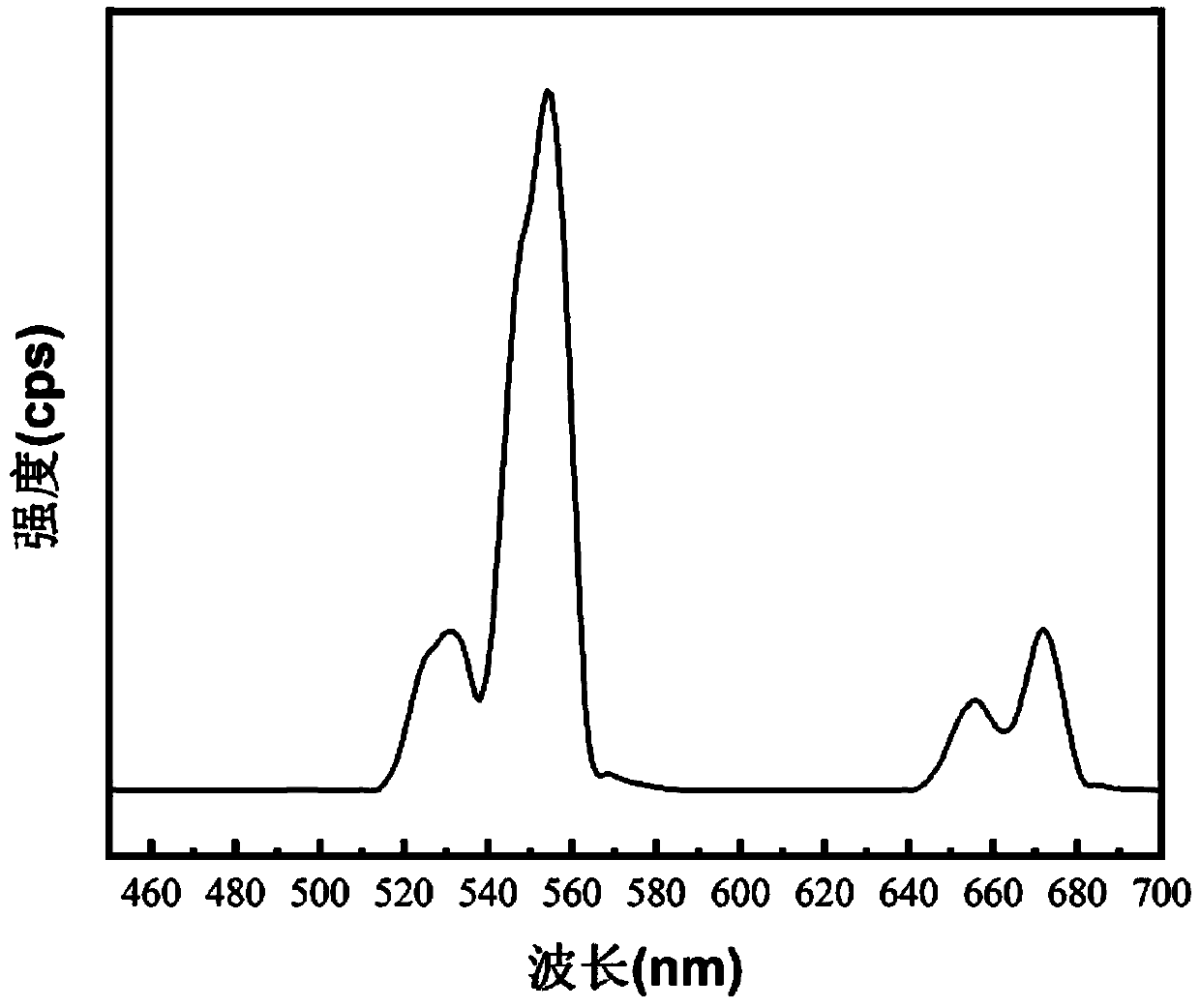

[0035]3. Preparation of rare earth hydroxyapatite precursor: mix hydroxyapatite, erbium oxide and ytterbium oxide, and then grind for 2h to 4h to obtain a mixed powder; calcinate the mixed powder at a temperature of 750...

specific Embodiment approach 2

[0056] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the particle size of the hydroxyapatite in step 3 is 40nm-900nm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0057] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the power of the ultrasonic dispersion described in Step 3 is 800W-1000W. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com