Preparation method of optical fiber puncture needle, slit and homogenizer for homogenizing light

A puncture needle and light homogenizer technology, applied in the field of medical devices, can solve problems such as the inability to control the direction of lateral light output, insufficient optical power density, and damage to the light homogenizer, so as to achieve high light output efficiency and therapeutic effect, and improve irradiation efficiency and treatment effect, the effect of enhancing the effect of irradiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

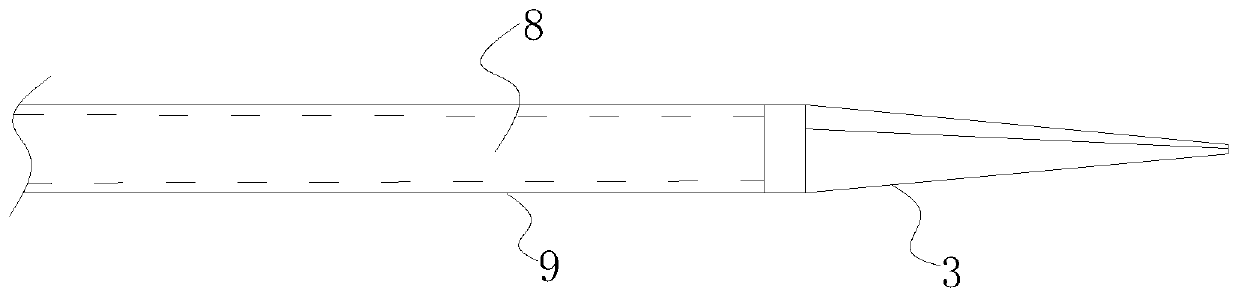

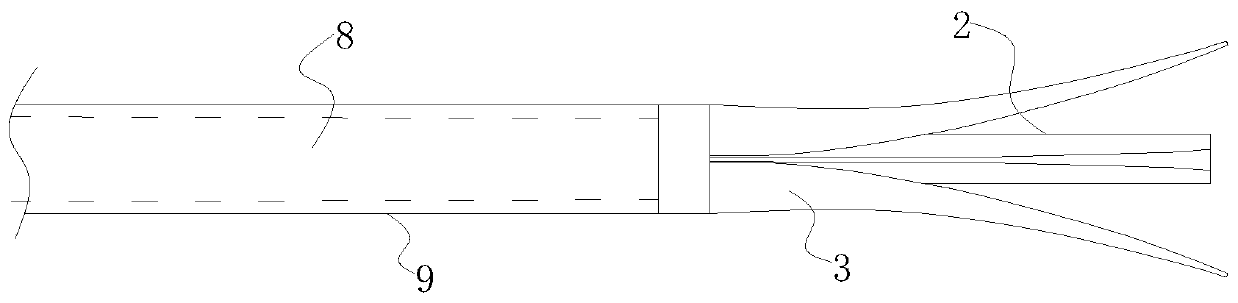

[0055] An optical fiber puncture needle for homogenizing light, which includes an optical fiber, the optical fiber includes a main body 8, and the main body 8 is connected with a homogenizer 2 capable of emitting light. like Figure 1-2 As shown in , since the optical fiber cannot be seen from the outside, the optical fiber is indicated by a dotted line.

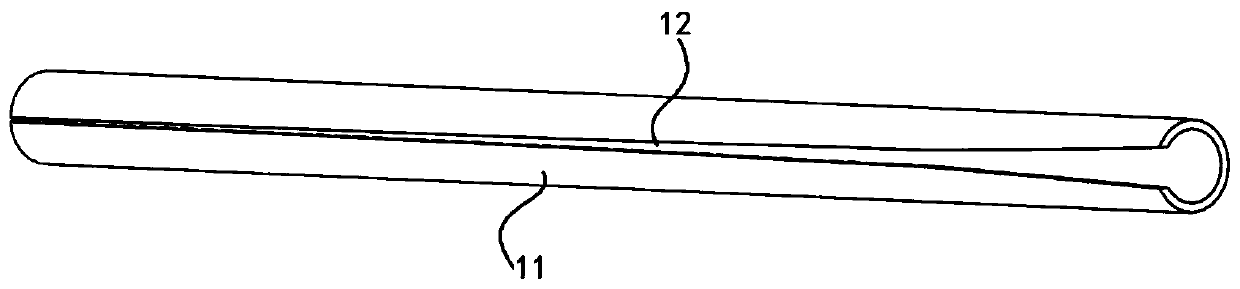

[0056] like image 3 As shown, the homogenizer 2 is a light guide device composed of a tubular structure or a rod-shaped structure. The light guide device includes a tube sleeve 11 whose inner wall has a reflection effect. If there are slits 12 on both sides that can emit light evenly, the light in the sleeve 11 can be evenly emitted from the slit 12. The slit can run through the entire length direction of the sleeve, or can be a part of the length direction of the sleeve. Set it up as needed.

[0057] The periphery of the main body 8 is wrapped with a main tube 9, and the periphery of the homogenizer 2 is provided with a...

Embodiment 2

[0070] On the basis of Example 1, the slit 12 capable of uniform light emission needs to meet the following conditions, that is, the change of the slit width with the length satisfies the formula ① Among them, d(z) is the width of the slit at z; L is the length of the sleeve; z is the length of the slit at the measurement point z along the transmission direction of the light; r is the inner diameter of the light guide device (that is, the length of the sleeve) Inner diameter); controlling the width of the slit through this formula ① can make the emitted light evenly distributed.

[0071] The transmittance of light in the slit 12 satisfies the formula ② Among them, T(z) is the transmittance of the light exiting from the slit 12 at z, L is the length of the sleeve; z is the length of the slit at the measuring point z along the transmission direction of the light; r is the light guide inside diameter of the device.

[0072] When the transmittance T(z)<1, the width of the slit...

Embodiment 3

[0077] On the basis of Embodiment 1 or 2, during the transmission of light in the sleeve, part of the light is output through the slit on the side. By controlling the width of the slit, the outgoing light can be evenly distributed, and the expression of the slit width d(z) is deduced below.

[0078] First, assume that the light transmission direction in the sleeve is the z direction, the inner diameter of the sleeve is r, the optical power at z in the sleeve is P(z), and the relationship between the optical power density I(z) and P(z) is:

[0079]

[0080] or

[0081] P(z)=πr 2 I(z) (2)

[0082] Assuming that the width of the slit at z is d(z), then the transmittance T(z) of the light exiting the sleeve at z is:

[0083]

[0084] Therefore, the optical power transmitted through the slit at z can be obtained as:

[0085] dP(z)=-I(z)T(z)2πrdz (4)

[0086] Now it is necessary to keep the transmitted light power uniform, that is, dP(z) is required to be a constant value, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com