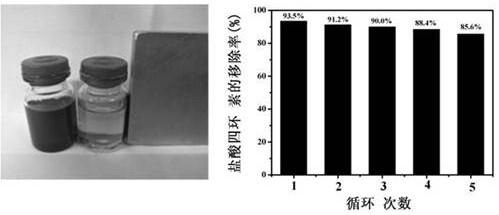

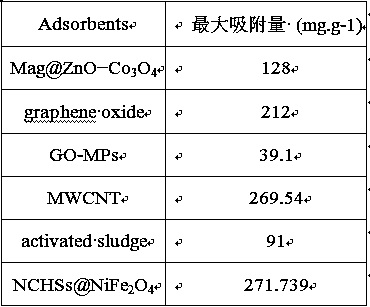

Preparation method of nanometer magnetic material NiFe2O4@ N-C for adsorbing tetracycline hydrochloride

A tetracycline hydrochloride and magnetic nanotechnology, applied in the field of adsorption, can solve the problem that environmental pollutants polluted by antibiotics have not been effectively removed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

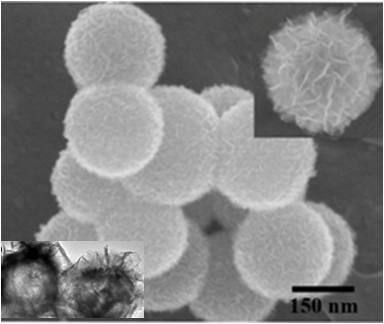

[0017] Example 1: Synthesis of NCHSs: Dissolve 12 mL of ethanol in water with a graduated cylinder, mix well, and drop 1 mL of NH 3 .H 2 0 (25%), after magnetic stirring at room temperature, slowly drop into 0.5 mL TEOS (tetraethyl silicate), continue to stir, then drop into 8 mL dopamine (50 mg / mL), stir for 32 h, centrifuge, wash, dry. The obtained black powder was transferred to a porcelain boat, and in a tube furnace with nitrogen as a protective gas, the temperature was programmed to rise to 800°C at 5 °C / min and kept for calcination for 3 h to obtain a black solid powder, namely NHCS balls, for future use.

[0018] NiFe 2 o 4 @ Synthesis of N–C: Weigh a small amount of NHCS spheres and dissolve them in 60ml of water, ultrasonically disperse, and then add 0.2 mmol Ni(NO 3 ) 2 .6H 2 O, 0.4 mmol Fe(NO 3 ) 3 .9H 2 O, 0.38 mmol sodium citrate, 1 mmol NH 4 F, 5 mmol urea, add while stirring, mix well and put into the kettle at 150°C for 36 h. After cooling, wash wit...

Embodiment 2

[0019] Example 2: Preparation of NHCS spheres in Example 1. The volume of ammonia water is 1-3 mL, the volume of ethanol is 10-15 mL, and then TEOS (tetraethyl silicate) is added in a volume of 0.5-1 mL, dopamine ( 50 mg / mL) in a volume of 7-9 mL.

Embodiment 3

[0020] Embodiment 3: For the NHCS ball described in Embodiment 1, the calcination temperature is 600-800°C, and the heating rate is 5-10°C / min.

[0021] Embodiment 3: the preparation hollow NiFe in embodiment 1 2 o 4 The Ni(NO 3 ) 2 .6H 2 O concentration is 0.2-0.6 mmol, Fe(NO 3 ) 3 .9H 2 The concentration of O is 0.4-1.2 mmol, and Ni(NO 3 ) 2 .6H 2 O: Fe(NO 3 ) 3 .9H 2 The molar ratio of O is 1:2; sodium citrate (0.35-0.4 mmol), NH 4 F (1-3 mmol), urea (5-10 mmol).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com