Method for preparing monatomic catalyst capable of degrading formaldehyde under oxygen condition and at normal temperature

A catalyst and conditional technology, which is applied in the field of single-atom catalyst preparation for catalytic oxidation of formaldehyde at room temperature, can solve the problems of poor stability, affecting catalytic activity, and easy deactivation, and achieve stable performance, strong anti-poisoning ability, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

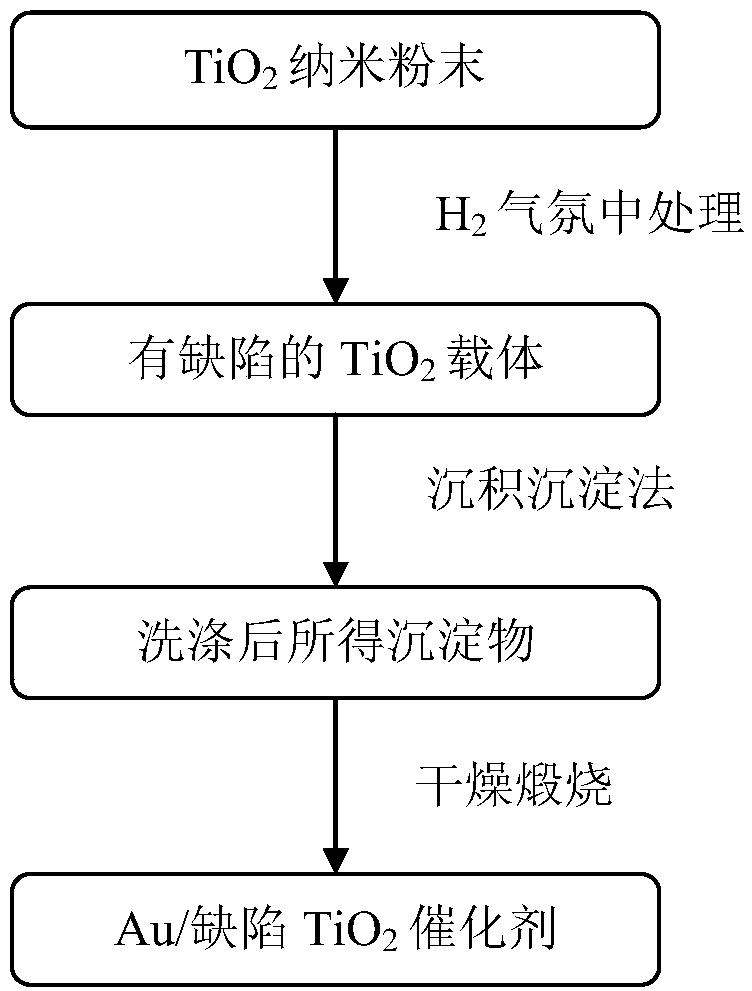

[0017] Based on the above mechanism, a method for preparing a single-atom catalyst for degrading formaldehyde at room temperature under an oxygen condition of the present invention comprises the following steps:

[0018] Step 1. TiO with a diameter of 40-60nm 2 The nano powder is placed in a tube furnace, and the gas flow rate is 50-100mL / min into the tube furnace. 2 and N 2 gas mixture, the H 2 and N 2 The volume ratio is 1:(18-20), and the temperature of the tube furnace is adjusted to 200-400°C for heat treatment of TiO 2 Nanopowder 1.5-2.5h to obtain defective TiO with surface oxygen vacancies 2 carrier;

[0019] Step 2, at first, will be 1: (45-55) described defective TiO with deionized water mass ratio 2 Suspend the carrier in deionized water, stir with a glass rod for 12-16min, add 0.8-1.2mol / L ammonium carbonate solution into the suspension to obtain solution A;

[0020] Then, the HAuCl with deionized water mass ratio of 1: (9.2-11.7) 4 4H 2 O was dissolved in...

Embodiment 1

[0024] Step 1, TiO with a diameter of 40nm 2 The nano-powder was placed in a tube furnace, and H 2 and N 2 gas mixture, the H 2 and N 2 The volume ratio is 1:18, and the temperature of the tube furnace is adjusted to 200°C for heat treatment of TiO 2 Nanopowders for 1.5h to obtain defective TiO with surface oxygen vacancies 2 carrier;

[0025] Step 2, first, the described defective TiO that is 1:45 with deionized water mass ratio 2 The carrier was suspended in deionized water, stirred with a glass rod for 12 minutes, and 0.8 mol / L ammonium carbonate solution was added to the suspension to obtain solution A;

[0026] Then, HAuCl with a mass ratio of 1:9.2 to deionized water 4 4H2 O was dissolved in deionized water, and then added dropwise to solution A to obtain solution B. In said solution B, ammonium carbonate and HAuCl 4 4H 2 The ratio of the amount of O species is 2:1, the defective TiO 2 Carrier and HAuCl 4 4H 2 The mass ratio of O is 10:1;

[0027] Finally, t...

Embodiment 2

[0031] Step 1, TiO with a diameter of 50nm 2 The nano-powder is placed in a tube furnace, and the gas flow rate is 75mL / min into the tube furnace. 2 and N 2 gas mixture, the H 2 and N 2 The volume ratio is 1:19, and the temperature of the tube furnace is adjusted to 300°C for heat treatment of TiO 2 Nanopowder 2h to obtain defective TiO with surface oxygen vacancies 2 carrier;

[0032] Step 2, first, the described defective TiO that will be 1:50 with deionized water mass ratio 2 The carrier was suspended in deionized water, stirred with a glass rod for 15 minutes, and 1mol / L ammonium carbonate solution was added to the suspension to obtain solution A;

[0033] Then, HAuCl with a mass ratio of 1:10.5 to deionized water 4 4H 2 O was dissolved in deionized water, and then added dropwise to solution A to obtain solution B. In said solution B, ammonium carbonate and HAuCl 4 4H 2 The ratio of the amount of O species is 2.5:1, the defective TiO 2 Carrier and HAuCl 4 4H 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com