Lanthanum-doped copper-manganese composite oxide catalyst and preparation method thereof

A technology of composite oxides and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor thermal stability and low-temperature catalytic activity, etc. To achieve the effect of easy process control and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the lanthanum-doped copper-manganese composite oxide catalyst of embodiment 1-4 of the present invention comprises the following steps:

[0047] 1) Dissolve manganese salt, copper salt and lanthanum salt in water and bathe in water for 0.5h, the temperature of water bath is 60°C;

[0048] 2) Add ammonium salt solution until the pH value is 8, and continue to stir for 2h;

[0049] 3) The precipitate is obtained, then dried and sintered, the sintering temperature is 550° C., and the sintering time is 2 hours, that is, a lanthanum-doped copper-manganese composite oxide catalyst is obtained.

[0050] Wherein, the manganese salt is 0.8mol of Mn(CH 3 COO) 2 4H 2 O;

[0051] Described copper salt is the Cu(NO of 0.2mol 3 ) 2 ·3H 2 O;

[0052] The lanthanum salt is La(NO 3 ) 3 ·6H 2 O;

[0053] The ammonium salt solution is 1.5mol / L (NH 4 ) 2 CO 3 ;

[0054] The drying temperature is 105°C, and the drying time is 12 hours.

[0055] La(...

PUM

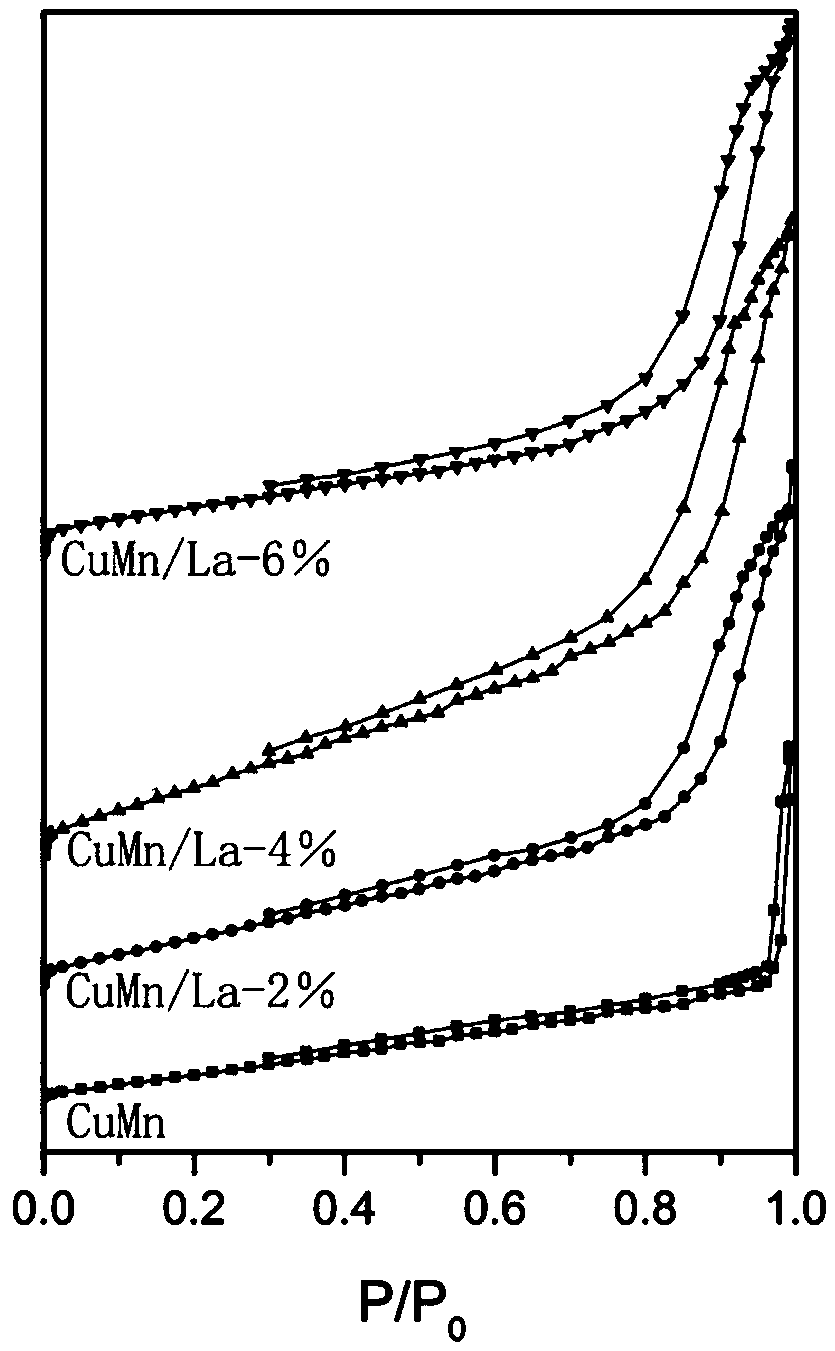

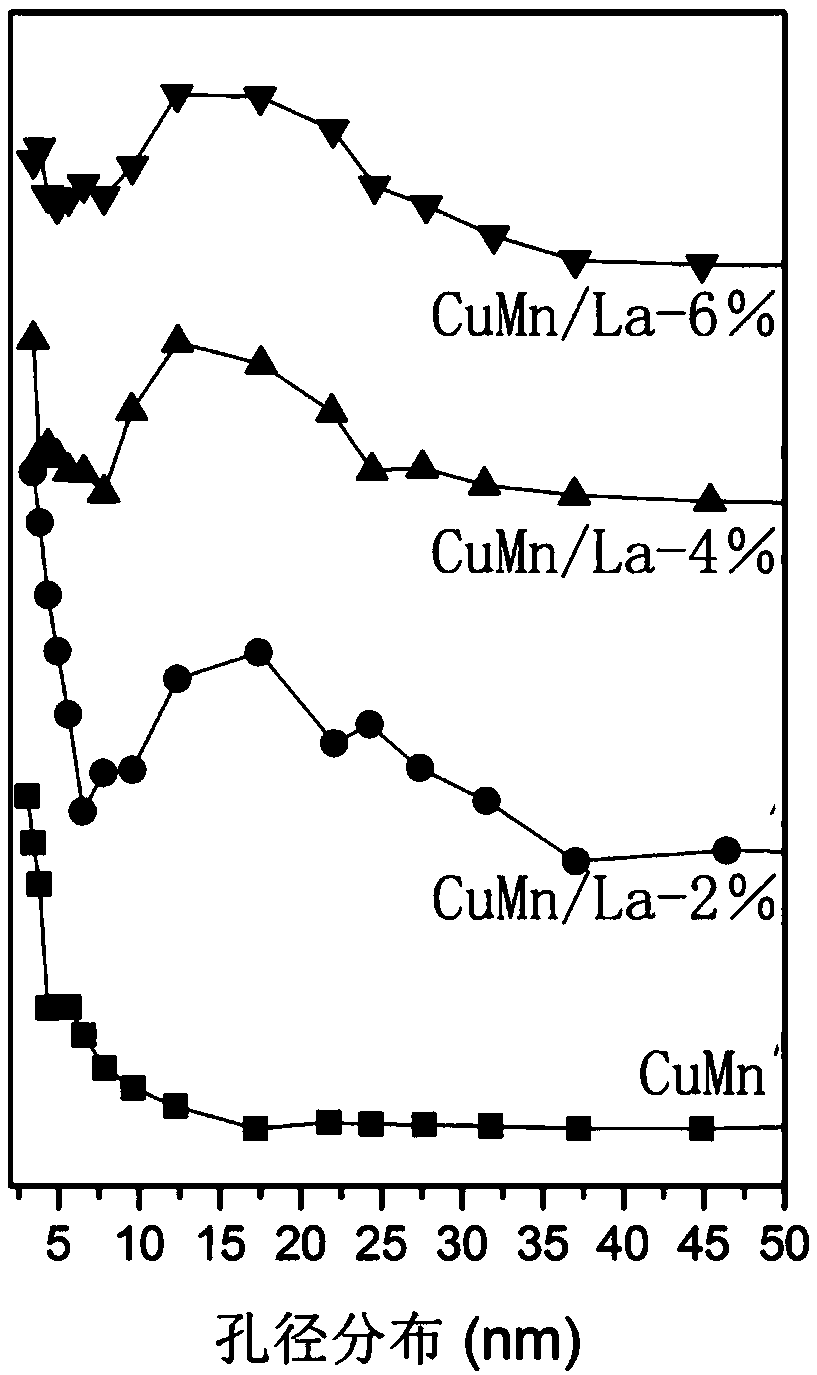

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com