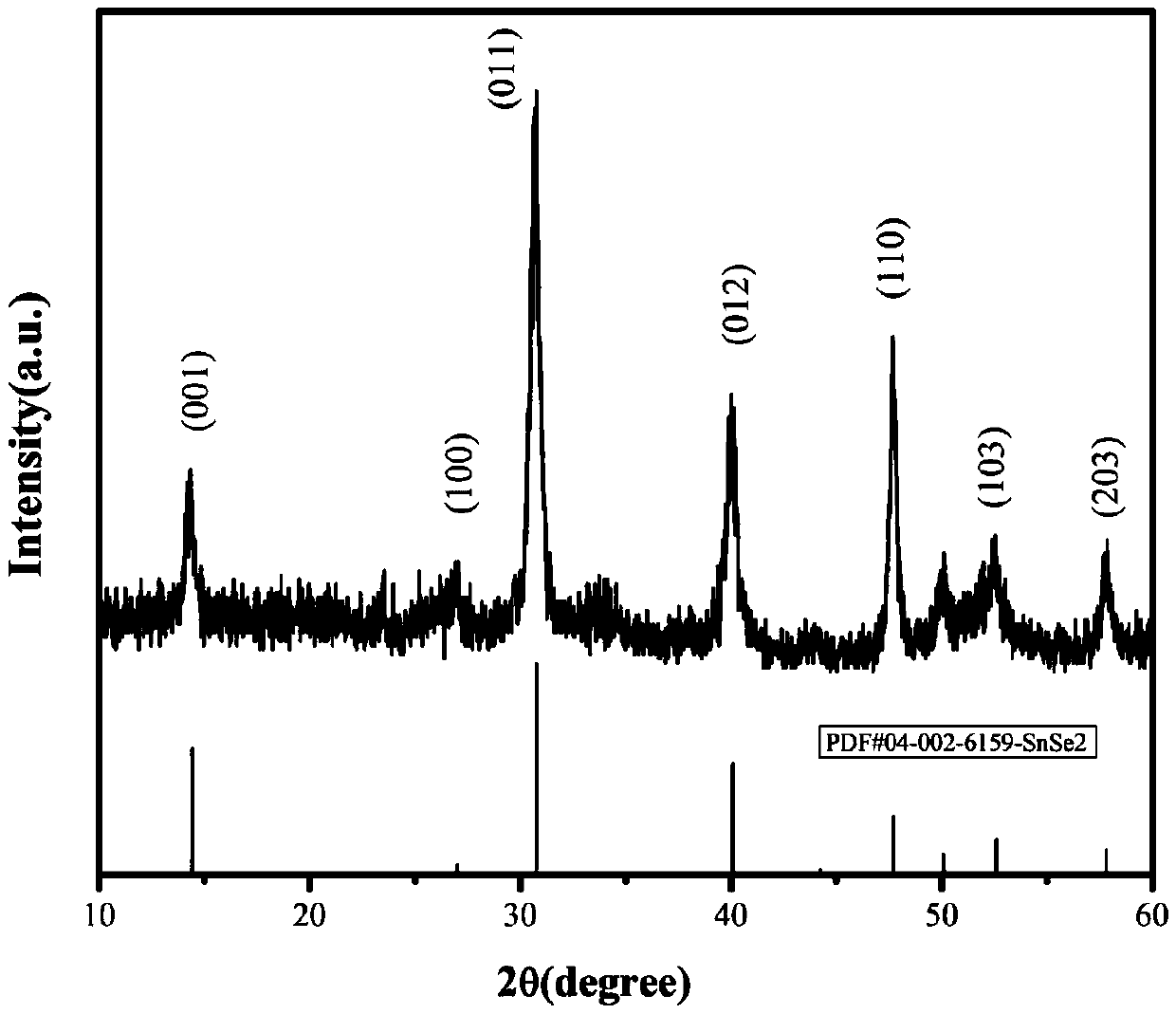

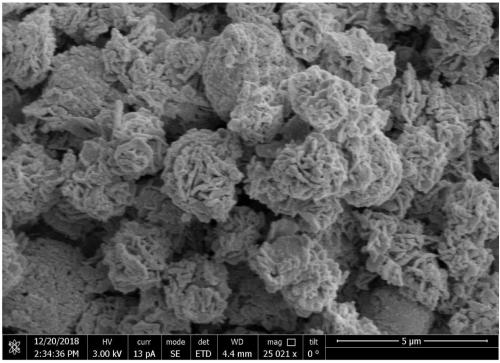

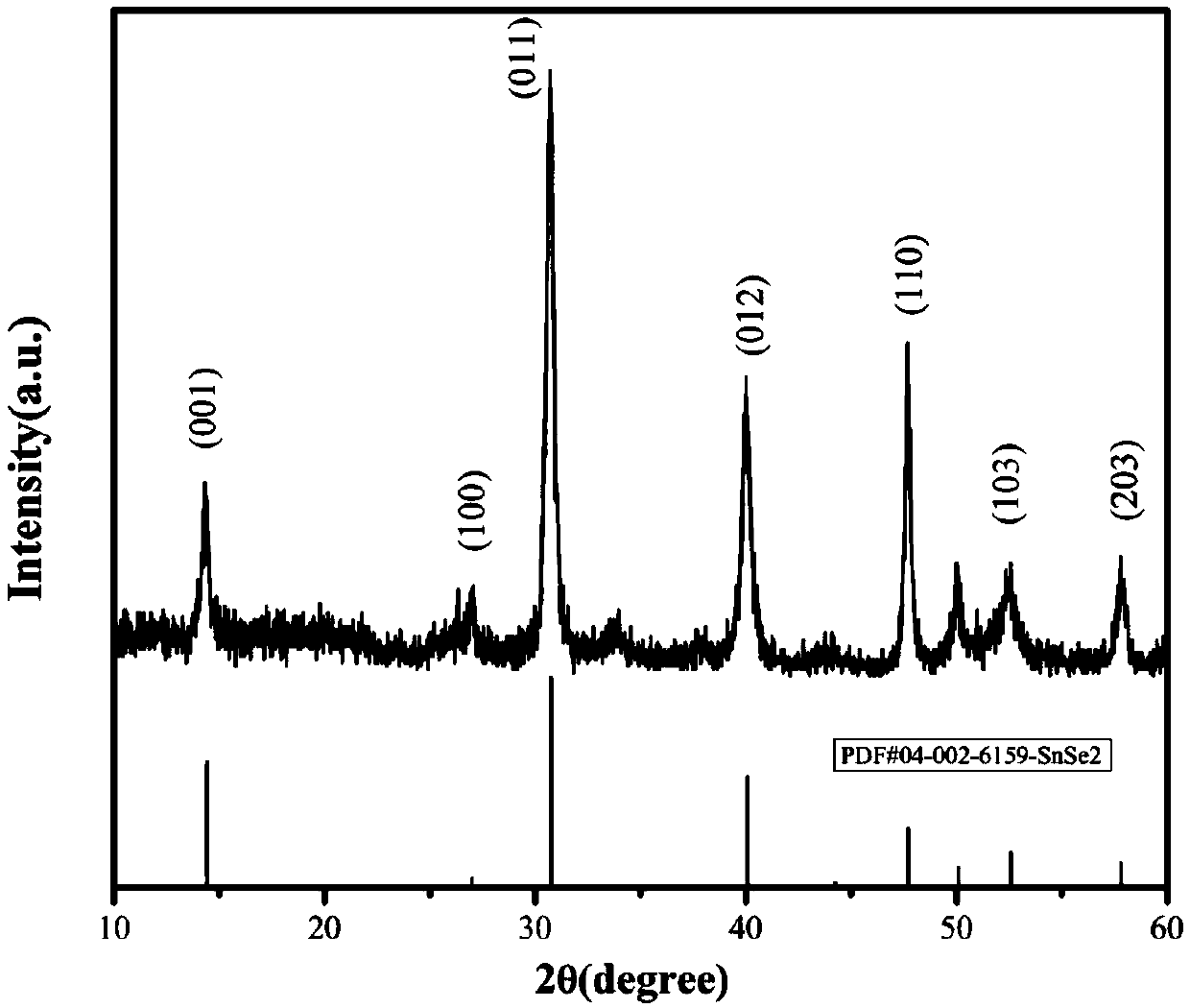

Method for preparing polycrystalline SnSe2 material by solution method

A solution method and solution technology are applied in the field of preparing polycrystalline SnSe2 materials by solution method, which can solve the problems of secondary pollution of the environment and human body, complicated use and complicated process, and achieve high operational accessibility, high repeatability, and preparation method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] First, inject 20 mL of oleic acid into a 50 mL two-necked bottle, and disperse the selenium powder in the solvent to obtain the precursor solution A of the selenium source. Then put the two-neck bottle into the magnetic stirrer and add a thermometer, let the thermometer just touch the liquid surface, turn on the rotary button, observe whether the rotor will touch the thermometer, coat the thermometer and condenser tube with vaseline, and assemble the instrument. After the assembly of the instrument is completed, stir the mixed solution A, set the rotation speed at 550r / min, and the temperature at 120°C, turn on the vacuum pump to start vacuuming, and keep warm for 30min. Then, high-purity nitrogen gas was introduced to raise the temperature to 260°C and keep the temperature for 2h. Weigh 1mmolSnCl during 2 , Measure 30ml of absolute ethanol in a test tube, add SnCl 2Dissolve in absolute ethanol to obtain mixed solution B. Cool the reaction down to 70°C, extract 6ml o...

Embodiment 2

[0048] First, inject 20 mL of oleic acid into a 50 mL two-necked bottle, and disperse the selenium powder in the solvent to obtain the precursor solution A of the selenium source. Then put the two-neck bottle into the magnetic stirrer and add a thermometer, let the thermometer just touch the liquid surface, turn on the rotary button, observe whether the rotor will touch the thermometer, coat the thermometer and condenser tube with vaseline, and assemble the instrument. After the assembly of the instrument is completed, stir the mixed solution A, set the rotation speed to 500r / min, and the temperature to 130°C, turn on the vacuum pump to start vacuuming, and keep warm for 25min. Then pass high-purity argon to raise the temperature to 250°C and keep it warm for 1.5h. Weigh 1mmolSnCl during 2 , Measure 30ml of absolute ethanol in a test tube, add SnCl 2 Dissolve in absolute ethanol to obtain mixed solution B. Cool the reaction down to 80°C, extract 7ml of precursor solution A ...

Embodiment 3

[0050] First, inject 20 mL of oleic acid into a 50 mL two-necked bottle, and disperse the selenium powder in the solvent to obtain the precursor solution A of the selenium source. Then put the two-neck bottle into the magnetic stirrer and add a thermometer, let the thermometer just touch the liquid surface, turn on the rotary button, observe whether the rotor will touch the thermometer, coat the thermometer and condenser tube with vaseline, and assemble the instrument. After the assembly of the instrument is completed, stir the mixed solution A, set the rotation speed at 600r / min, the temperature at 140°C, turn on the vacuum pump to start vacuuming, and keep warm for 25min. Then, high-purity nitrogen gas was introduced to raise the temperature to 270°C and keep the temperature for 2.5h. Weigh 1mmolSnCl during 2 , Measure 30ml of absolute ethanol in a test tube, add SnCl 2 Dissolve in absolute ethanol to obtain mixed solution B. Cool the reaction down to 90°C, extract 5ml of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com