Technology for oxidizing organic wastewater by mixing pyrite and biocha

A technology of organic wastewater and oxidation treatment, applied in the direction of oxidized water/sewage treatment, special compound water treatment, water/sewage treatment, etc., can solve the problems of mine acid wastewater pollution, easy to be oxidized, unstable, etc., and achieve excellent treatment effect Good, promote oxidation removal, strengthen the effect of promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

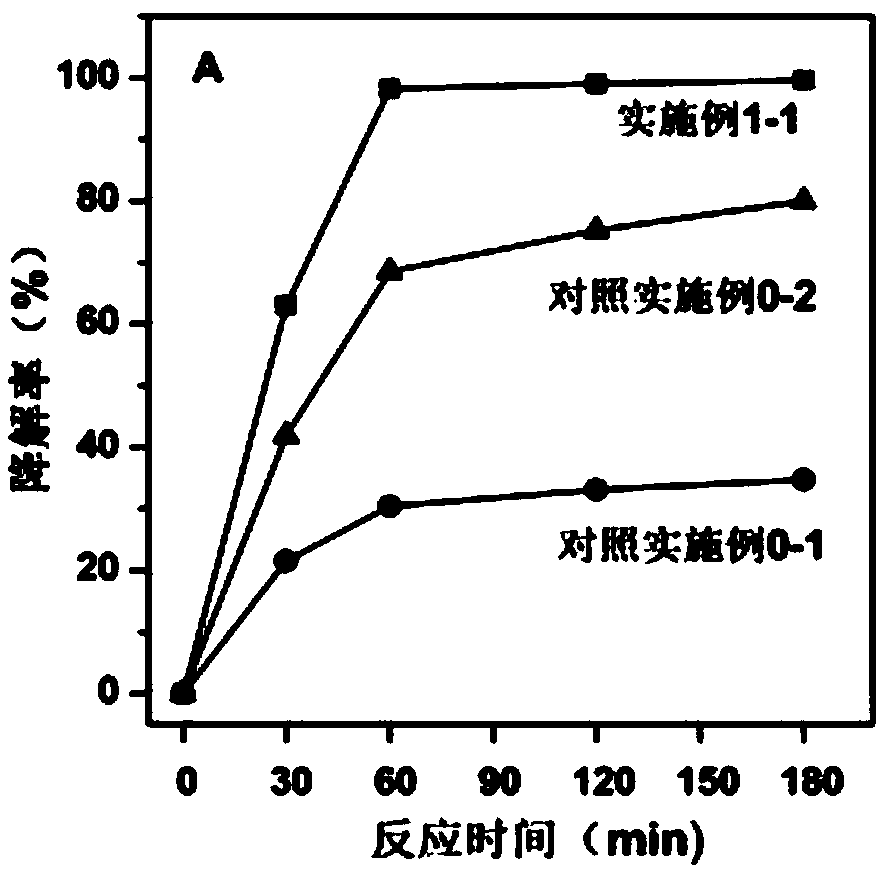

[0028] Embodiment 1-1: Treatment of simulated dye wastewater

[0029] Step 1: Biochar Heat Treatment

[0030] Weigh 500g of biochar, put it into 2L of ferrous sulfate (0.4mol / L) solution with a mass concentration of 11%, and immerse it for 60min, then centrifuge to separate the solid matter, and put it into a tube furnace for vacuum heat treatment at 400°C for 2h , cooled, and crushed through a 100-mesh sieve to obtain heat-treated biochar.

[0031] Step 2: Fenton Oxidation Process

[0032] Prepare 500mL of rhodamine B solution with a concentration of 200mg / L, and use it as simulated dye wastewater. Add 15g of heat-treated biochar and 7.5g of pyrite in the dye wastewater in turn (converted additions are 30 and 15g / L respectively), stir and mix evenly, then add 5mL of hydrogen peroxide with a concentration of 1mol / L Solution (converted hydrogen peroxide addition amount is 10mmol / L), stirring continuous reaction. Take liquid samples when reacting for 30, 60, 120, and 180 min...

Embodiment 1-2

[0033] Embodiment 1-2: Treatment of antibiotic wastewater

[0034] The initial COD value of antibiotic wastewater from a pharmaceutical factory producing cephalosporins was 600mg / L. Add 40g of heat-treated biochar and 20g of pyrite in 1L of the waste water in succession in Example 1-1, stir and mix evenly, then add 15mL of hydrogen peroxide solution with a concentration of 1mol / L, and stir for continuous reaction for 120 and 180min. The COD values in the waste water were sampled and measured to be 33 and 17 mg / L respectively. That is, after 180 minutes of treatment, the COD value in the wastewater meets the requirements of the Class A wastewater discharge standard (<20mg / L).

Embodiment 2-1、2-2、2-3

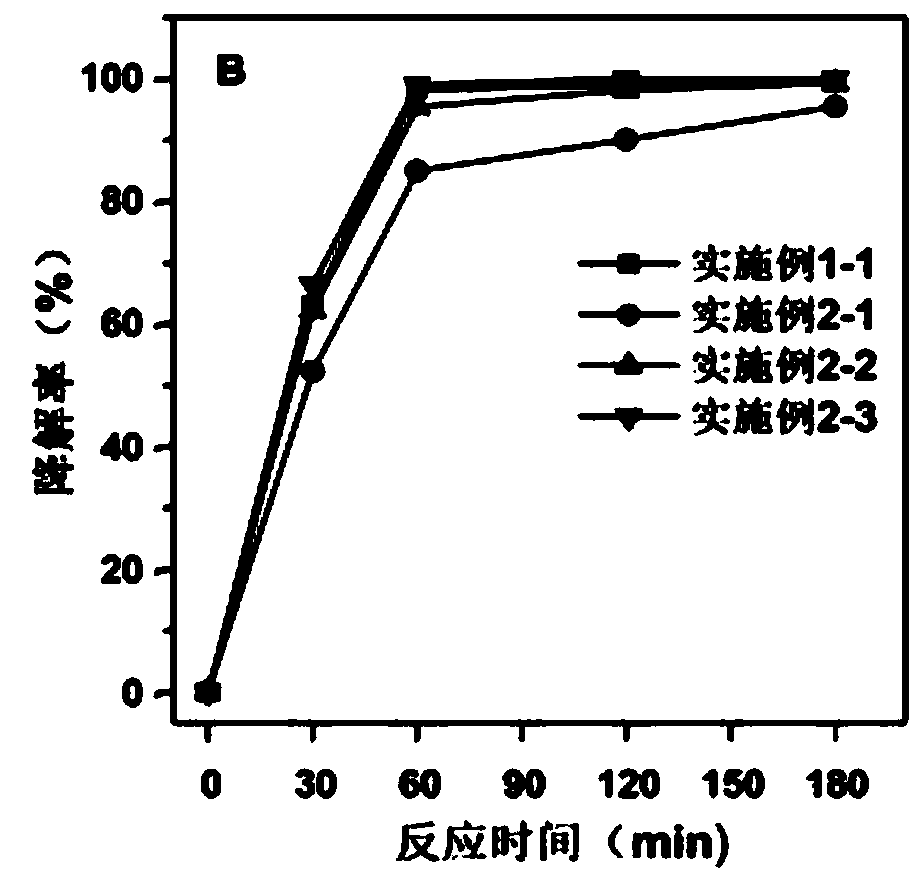

[0039] Embodiment 2-1, 2-2, 2-3: Based on embodiment 1-1, when using ferrous salt to impregnate biochar in the first step, change the concentration of ferrous salt to 0.1, 0.3, 0.5mol / L respectively , and other subsequent processing conditions are the same. The degradation rate results of Rhodamine B in dye wastewater are shown in Figure 1B .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com