Method for mitigating MBR membrane fouling by using lanthanide compound

A lanthanide compound and membrane fouling technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low selectivity of synthetic polymer additives, adverse effects of microbial activity, no Add lanthanide compounds and other problems to achieve the effect of improving the surface properties of sludge, increasing the maximum degradation rate, and slowing down membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

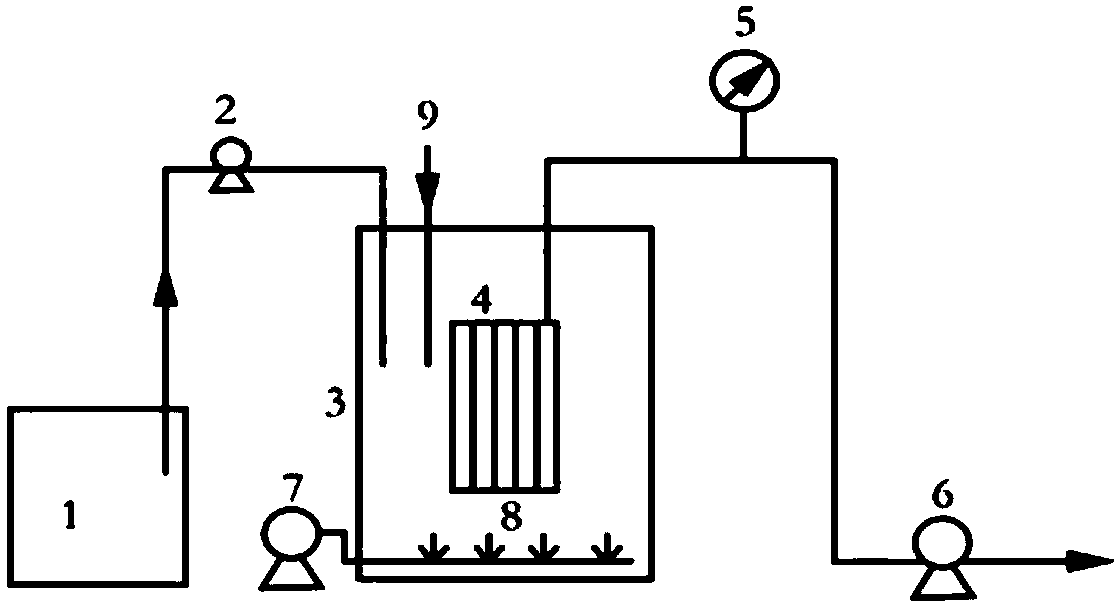

Image

Examples

Embodiment 1

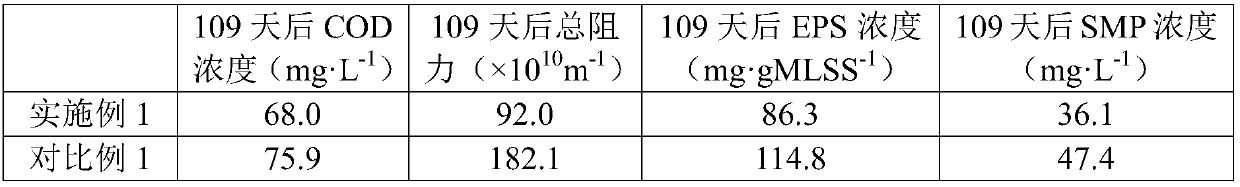

[0024] Carry out sludge cultivation in the membrane bioreactor 3, when the sludge concentration in the membrane bioreactor 3 reaches 6000mg / L, add lanthanum chloride to the membrane bioreactor 3, the dosing concentration of lanthanum chloride is 60mg / L . Stable operating parameters of membrane bioreactor: Influent COD of a printing and dyeing wastewater in Shanghai is 600-900mg·L -1 , the pH is about 6-8, the temperature is about 25°C, and the aeration rate is 0.2m 3 / h. When the bioreactor was discharging sludge during operation, the lanthanide compound was supplemented to keep the lanthanum ion concentration at 50-70 mg / L. After the membrane bioreactor system operated stably for 109 days, the implementation results are shown in Table 1.

Embodiment 2

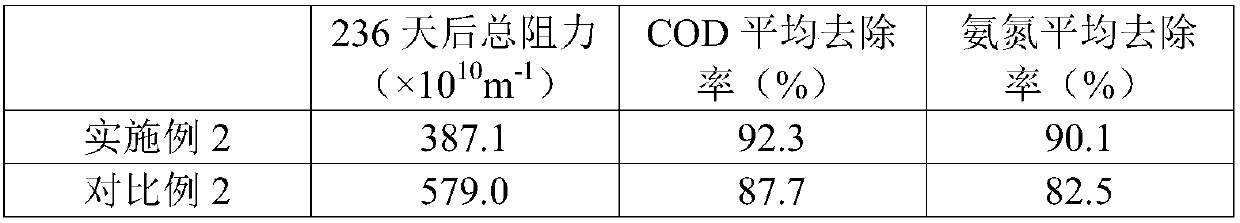

[0031] Carry out sludge cultivation in the membrane bioreactor 3, when the sludge concentration in the membrane bioreactor 3 reaches 6000mg / L, add lanthanum chloride to the membrane bioreactor 3, the dosing concentration of lanthanum chloride is 60mg / L . Stable operating parameters of membrane bioreactor: a salty wastewater in Shanghai, with a salinity of about 3% and a COD of 600-900 mg·L -1 , ammonia nitrogen is 14mg·L -1 The pH is about 6~8, the temperature is about 25°C, and the aeration rate is 0.2m 3 / h. When the bioreactor is discharging sludge during operation, the lanthanide compound is supplemented to keep the lanthanum ion concentration at 50-70mg / L. After 236 days of stable operation of the membrane bioreactor system, the implementation results are shown in Table 2.

Embodiment 3

[0038] Carry out sludge cultivation in the membrane bioreactor 3, when the sludge concentration in the membrane bioreactor 3 reaches 6000mg / L, add lanthanum chloride to the membrane bioreactor 3, the dosing concentration of lanthanum chloride is 60mg / L . Stable operating parameters of membrane bioreactor: Influent COD of a printing and dyeing wastewater in Shanghai is 600-900mg·L -1 , the pH is about 6-8, the temperature is about 25°C, and the aeration rate is 0.2m 3 / h. During the operation, when the bioreactor sludge was discharged, the lanthanide compound was supplemented to keep the lanthanum ion concentration at 50-70 mg / L. After the membrane bioreactor system operated stably for 176 days, the implementation results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com