A kind of cross-linking polymerization preparation method of polyionic liquid solid state electrolyte

A solid electrolyte, polyionic liquid technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve problems such as complex preparation process, and achieve the effects of simple and mild synthesis conditions, stable electrochemical properties, and good cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment includes the following steps:

[0024] (1), Weigh 5g of polyethylene oxide PEO and add it to a round bottom flask, then add 110mL of acetonitrile and 5g of 1-vinyl-3-methylimidazole bistrifluoromethanesulfonimide [VMIM]TFSI monomer, after stirring Add 1.1 g lithium bistrifluoromethanesulfonimide LiTFSI, stir for 5 hours to obtain a mixed solution;

[0025] (2), add the polyethylene glycol diacrylate PEGDA of 3.7g in the mixed liquor that step (1) prepares as crosslinking agent and initiator azobisisobutyronitrile AIBN0.1g, stir; It is heated, The cross-linking polymerization reaction temperature is 70°C, and the reaction time is 24 hours;

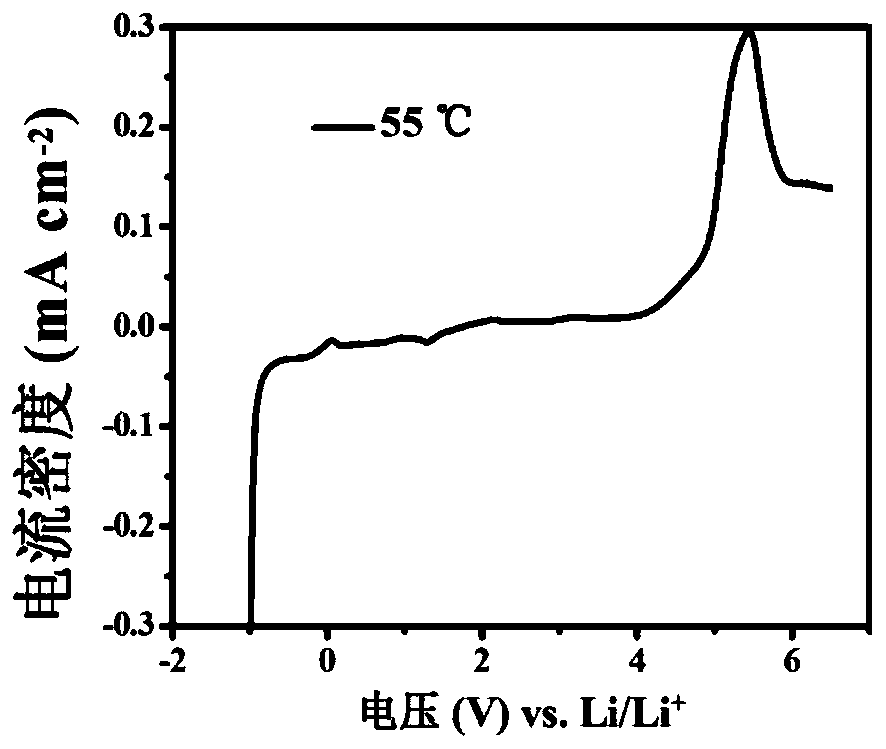

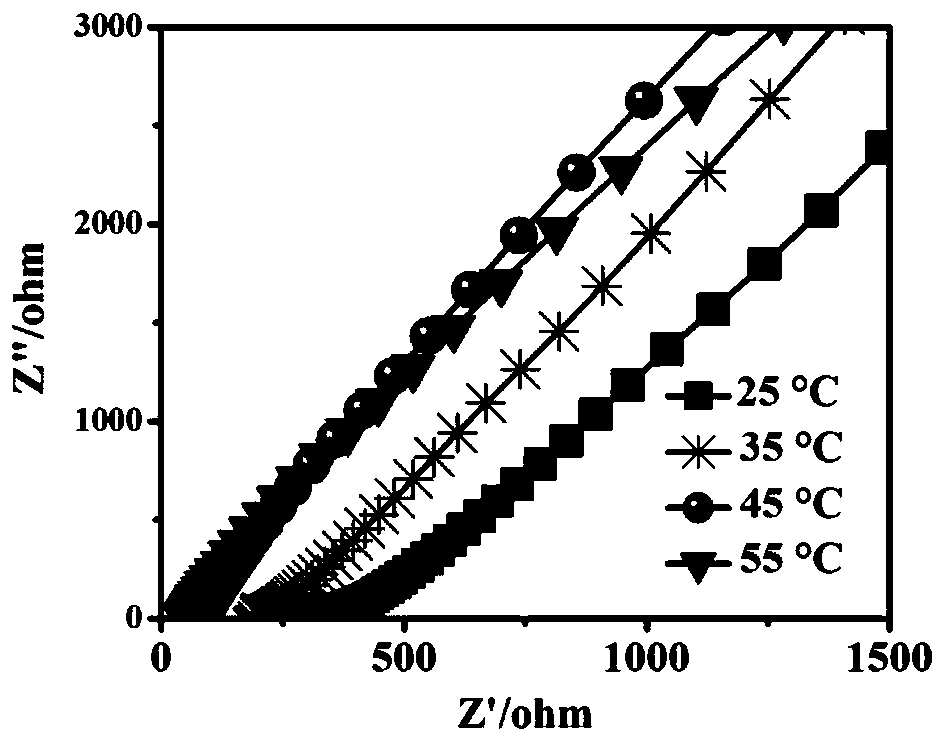

[0026] (3) After the reaction system in step (2) was cooled to room temperature, the obtained polyionic liquid solid electrolyte was vacuum-dried at 80° C. for 48 hours, and punched into discs with a diameter of 1.9 cm by a tablet machine for later use. Optical photos of the appearance of the electrolyte and flexibl...

Embodiment 2

[0032] This embodiment includes the following steps:

[0033] (1) Weigh 6.7g of PEO into a round bottom flask, add 125mL of acetonitrile and 3.3g of 1-vinyl-3-methylimidazole bistrifluoromethanesulfonimide [VMIM]TFSI monomer, stir with magnetic force After stirring, add 1.1 g of lithium bistrifluoromethanesulfonimide LiTFSI, and stir for 5 hours to obtain a mixed solution;

[0034] (2), add 2.5g of polyethylene glycol diacrylate PEGDA to the mixed solution prepared in step (1) as crosslinking agent and initiator azobisisobutyronitrile AIBN 0.07g, stir, it is heated, The cross-linking polymerization reaction temperature is 73°C, and the reaction time is 24 hours;

[0035](3) After the reaction system in step (2) was cooled to room temperature, the obtained polyionic liquid solid electrolyte was vacuum-dried at 80° C. for 48 hours, and punched into discs with a diameter of 1.9 cm by a tablet machine for later use. Optical photos of the appearance of the electrolyte and flexibl...

Embodiment 3

[0037] This embodiment includes the following steps:

[0038] (1), weigh 7.8g polyethylene oxide PEO and join in the round bottom flask, add acetonitrile 150mL and 2.2g 1-vinyl-3-methylimidazole bistrifluoromethanesulfonimide [VMIM]TFSI monomer, use Stir with a magnetic stirrer, add 1.1 g of lithium bistrifluoromethanesulfonimide LiTFSI, and stir for 5 hours to obtain a mixed solution;

[0039] (2), add 1.6g of polyethylene glycol diacrylate PEGDA to the mixed solution prepared in step (1) as crosslinking agent and initiator azobisisobutyronitrile AIBN 0.05g, stir, it is heated, The cross-linking polymerization reaction temperature is 75°C, and the reaction time is 24 hours;

[0040] (3) After the reaction system in step (2) was cooled to room temperature, the obtained polyionic liquid solid electrolyte was vacuum-dried at 80° C. for 48 hours, and punched into discs with a diameter of 1.9 cm by a tablet machine for later use. Optical photos of the appearance of the electroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com