A kind of preparation method of nano silicon nitride fiber/epoxy resin composite material

A nano-silicon nitride and epoxy resin technology is applied in the field of polymer composite materials, which can solve the problems of lack of nano-epoxy composite materials and difficulty in forming a thermally conductive network.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

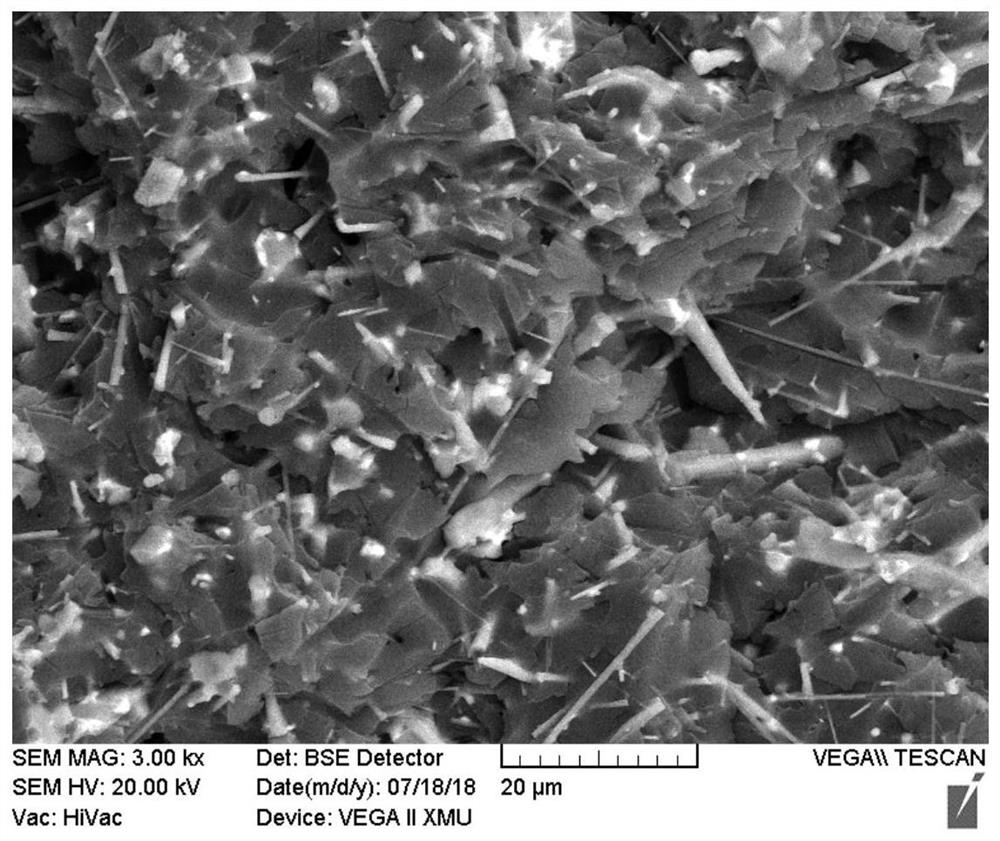

[0024] 1) Preparation of porous nano-silicon nitride fiber frame: 20wt% carbon nanotubes, 70wt% 0.2 μm α-Si 3 N 4 , and 10wt% Y 2 o 3 The mixed powder is molded to form a green body, and the molding pressure is 20 MPa; the SiO powder is placed at the bottom of the crucible, wherein the mass ratio of SiO and carbon nanotubes is 10:1, and the green body is placed on the porous BN support in the middle of the crucible, and then Put the crucible in a multifunctional sintering furnace, feed nitrogen, and keep it at 1500°C for 6 hours. The temperature rise rate from room temperature to 1100°C is 500°C / h, and the temperature rise rate from 1100°C to 1500°C is 100°C / h. h, carry out carbothermal reduction and nitriding reaction to form a porous silicon nitride green body, in which the mass ratio of SiO and carbon nanotubes is 10:1; continue to heat up to 1750 ° C for liquid phase sintering, keep warm for 0.5 hours, and the heating rate is 100 ° C / h, a phase transition occurs during...

Embodiment 2

[0027] 1) Preparation of porous nano-silicon nitride fiber framework: 50wt% carbon nanotubes, 30wt% 0.5 μm α-Si 3 N 4 , and 20wt% Yb 2 o 3 The mixed powder is molded to form a green body, and the molding pressure is 40MPa; the SiO powder is placed at the bottom of the crucible, wherein the mass ratio of SiO and carbon nanotubes is 8:1, and the green body is placed on the porous BN support in the middle of the crucible, and then Put the crucible in a multi-functional sintering furnace, feed nitrogen, and keep warm at 1600°C for 3 hours. The temperature rise rate from room temperature to 1100°C is 700°C / h, and the temperature rise rate from 1100°C to 1600°C is 300°C / h. h, carry out carbothermal reduction and nitriding reaction to form a porous silicon nitride green body, in which the mass ratio of SiO and carbon nanotubes is 10:1; continue to heat up to 1850 ° C for liquid phase sintering, the heating rate is 100 ° C / h, keep warm After 2 hours, a phase transition occurred d...

Embodiment 3

[0030]1) Preparation of porous nano-silicon nitride fiber framework: 90wt% carbon nanotubes, 10wt% La 2 o 3 After the mixed powder is molded to form a green body, the molding pressure is 80 MPa; the SiO powder is placed at the bottom of the crucible, wherein the mass ratio of SiO and carbon nanotubes is 12:1, and the green body is placed on the porous BN support in the middle of the crucible, and then Put the crucible in a multi-functional sintering furnace, blow in nitrogen, and keep warm at 1700°C for 1 hour. The temperature rise rate from room temperature to 1100°C is 600°C / h, and the temperature rise rate from 1100°C to 1700°C is 200°C / h. h, carry out carbothermal reduction and nitriding reaction to form a porous silicon nitride body, in which the mass ratio of SiO and carbon nanotubes is 10:1; continue to heat up to 1800 ° C for liquid phase sintering, the heating rate is 200 ° C / h, heat preservation In 2 hours, a phase transition occurred during this process, that is,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com