Preparation method of sintered neodymium-iron-boron with high corrosion resistance and machinability

A high corrosion resistance, NdFeB technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of low ductility, drop corners, edge drop, spotting knife wire, high hardness of NdFeB, etc. Achieve the effects of enhanced ductility, improved corrosion resistance and machinability, and improved processing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) The NdFeB steel ingot is prepared by the ingot casting process, and its nominal composition atomic percentage is:

[0016] Pr is 2.27%, Nd is 11.03%, B is 6.02%, Dy is 0.59%, Co is 1.12%, V is 0.26%, Zn is 1.6%, Al is 1.22%, Cu is 0.16%, Fe is 75.73%,

[0017] (2) Use the hydrogen crushing-jet milling process to make powder, and the average particle size of NdFeB particles after powder making is 3.5um;

[0018] (3) Compressed in a 1.7T magnetic field;

[0019] (4) Perform isostatic pressing on the formed green body under a pressure of 130-200Mpa for 5-20 seconds;

[0020] (5) Carry out the corrosion resistance weight loss test of the magnetic performance test box and the slice yield statistics in actual production. The conditions of the weight loss test are pressure 2 atmospheres, temperature 120°C, humidity 100% RH, and time 72 hours.

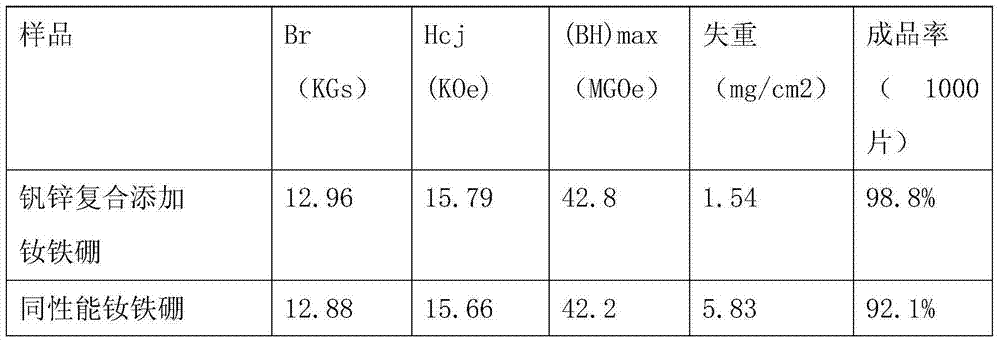

[0021] The performance of the samples prepared by the above process is compared with ordinary NdFeB as follows:

[0022]

Embodiment 2

[0024] (1) The NdFeB steel ingot is prepared by ingot casting, and its nominal composition atomic percentage is:

[0025] Pr is 3.25%, Nd is 10.15%, B is 5.9%, Dy is 0.39%, Co is 1.42%, V is 0.28%, Zn is 2.2%, Al is 0.53%, Cu is 0.22%, Fe is 75.66%, ;

[0026] (2) Use the hydrogen crushing-jet milling process to make powder, and the average particle size of NdFeB particles after powder making is 3.3um;

[0027] (3) Compressed in a 1.7T magnetic field;

[0028] (4) Carry out 130-200M of the formed green body p Carry out isostatic pressing under the pressure of a for 5-20 seconds;

[0029] (5) Carry out the corrosion resistance weight loss test of the magnetic performance test box and the slice yield statistics in actual production. The conditions of the weight loss test are pressure 2 atmospheres, temperature 120°C, humidity 100% RH, and time 72 hours.

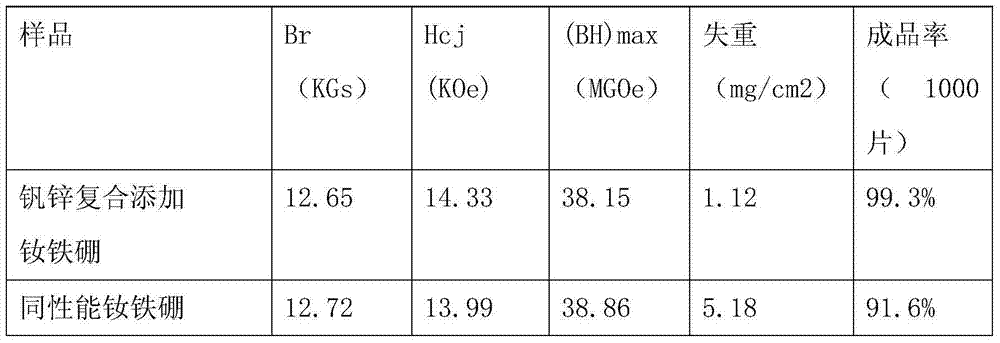

[0030] The performance of the samples prepared by the above process is compared with ordinary NdFeB as follows:

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com