Isocyanate (environment-friendly) binder for particleboards and preparation method of binder

A technology of isocyanate and diisocyanate, which is applied in the field of preparation of paper-making additives and isocyanate adhesives for particleboard, can solve the problems of poor water resistance, low bonding strength, and high price, and achieve simplified process, enhanced physical strength, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

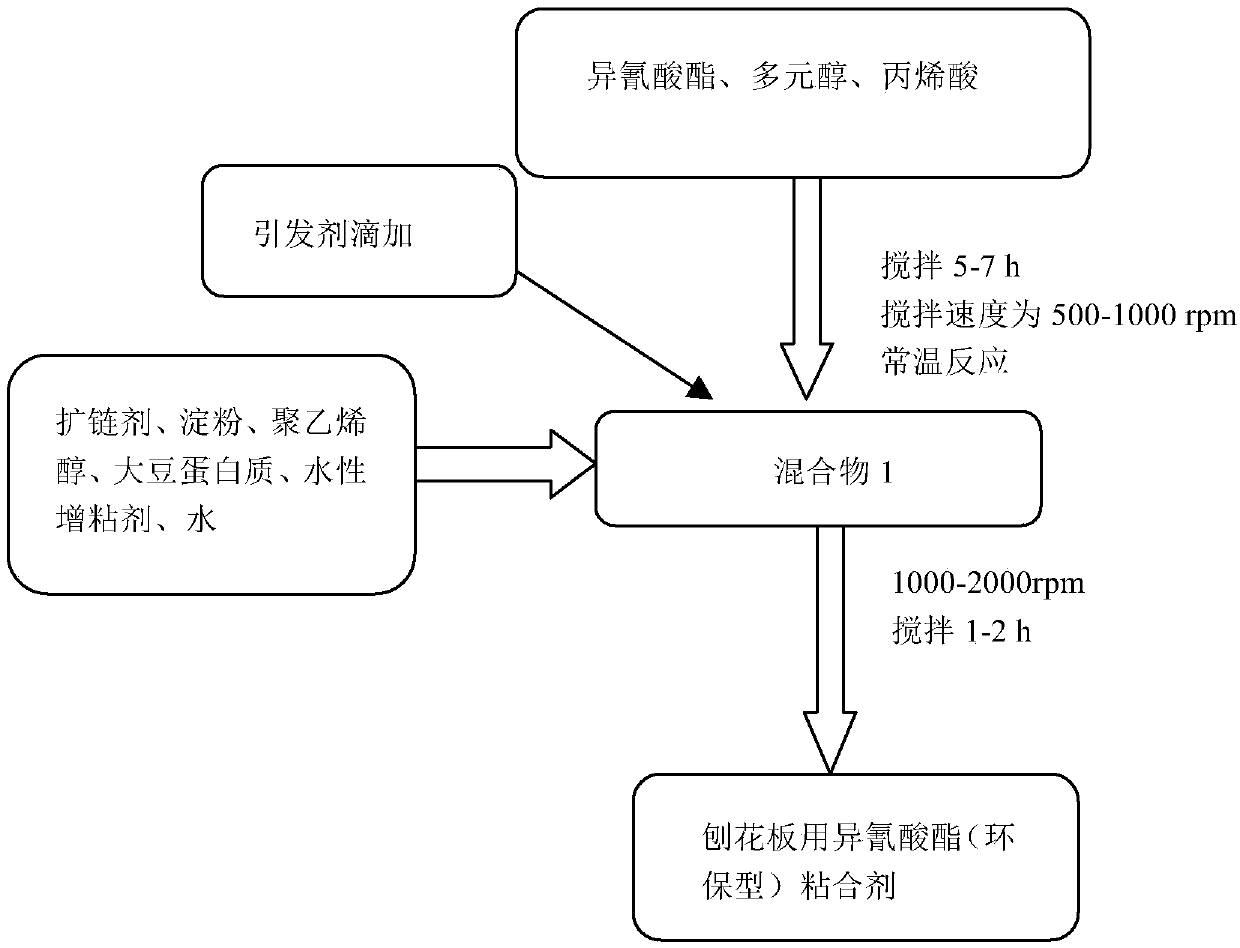

Method used

Image

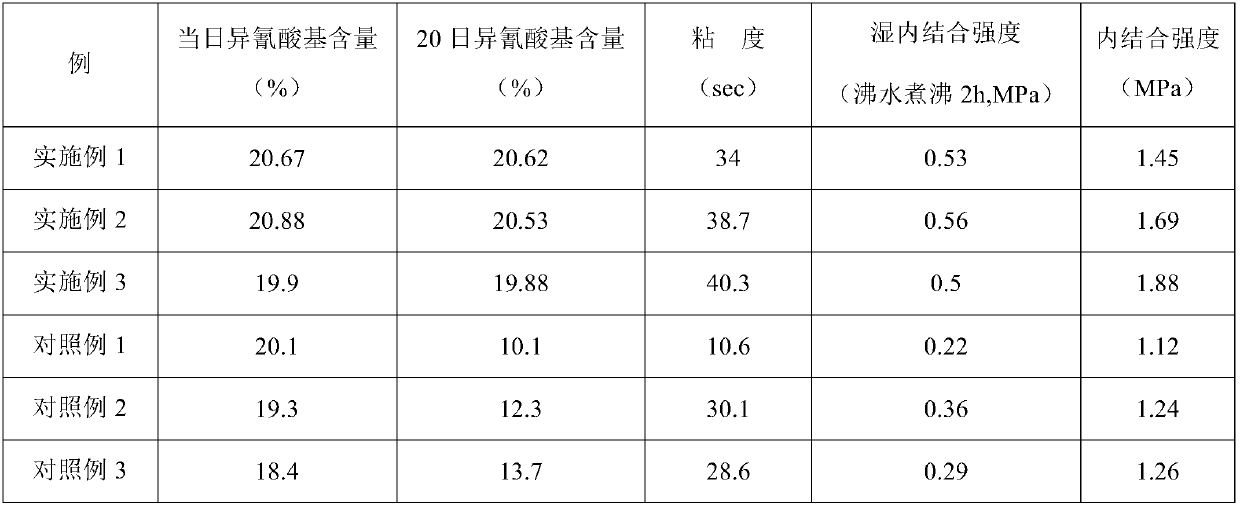

Examples

Embodiment 1

[0033] The invention provides a kind of preparation method of isocyanate (environmental protection type) adhesive for particleboard, and concrete steps comprise:

[0034] (1) In a nitrogen protective atmosphere, add 30 parts of toluene diisocyanate (TDI), 50 parts of sorbitol, and 5 parts of acrylic acid in the reactor, and slowly add 1 part of potassium persulfate dropwise at a rate of 1 mL / min. Fully stir for 5 hours, the stirring speed is 500rpm, and react at room temperature;

[0035] (2) Add 1 part of glycerin, 3 parts of corn starch, 3 parts of polyvinyl alcohol, 5 parts of soybean protein, 1 part of water-based thickener, 100 parts of water, 1000 rpm, and stir for 1 hour;

[0036] (3) After the reaction is finished, the isocyanate (environment-friendly) adhesive for particleboard can be obtained.

Embodiment 2

[0038] The invention provides a kind of preparation method of isocyanate (environmental protection type) adhesive for particleboard, and concrete steps comprise:

[0039] (1) In a nitrogen protective atmosphere, add 35 parts of isophorone diisocyanate (IPDI), 55 parts of pentaerythritol, and 8 parts of acrylic acid in the reactor, and slowly add 2 parts of tert-butyl hydroperoxide dropwise at the same time. 1.5mL / min, fully stirred for 6h, the stirring speed was 800rpm, and reacted at room temperature;

[0040] (2) Add 2 parts of 1,4-butanediol, 4 parts of corn starch, 4 parts of polyvinyl alcohol, 6 parts of soybean protein, 2 parts of water-based thickener, 150 parts of water, 2000 rpm, and stir for 2 hours;

[0041] (3) After the reaction is finished, the isocyanate (environment-friendly) adhesive for particleboard can be obtained.

Embodiment 3

[0043] The invention provides a kind of preparation method of isocyanate (environmental protection type) adhesive for particleboard, and concrete steps comprise:

[0044] (1) In a nitrogen protective atmosphere, add 40 parts of diphenylmethane diisocyanate (MDI), 60 parts of ethylene glycol, and 10 parts of acrylic acid in the reactor, and slowly add 3 parts of ammonium persulfate dropwise at a rate of 2mL / min, fully stirred for 7h, with a stirring speed of 1000rpm, and reacted at room temperature;

[0045] (2) Add 3 parts of trimethylolpropane, 5 parts of potato starch, 5 parts of polyvinyl alcohol, 7 parts of soybean protein, 3 parts of water-based thickener, 200 parts of water, 2000 rpm, and stir for 2 hours;

[0046] (3) After the reaction is finished, the isocyanate (environment-friendly) adhesive for particleboard can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com