A kind of graphitic phase carbon nitride-(110) bismuth vanadate z-type heterojunction photocatalyst and its preparation method and application

A graphite-phase carbon nitride and photocatalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve poor carrier separation efficiency, photogenerated electron-hole pair recombination rate advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

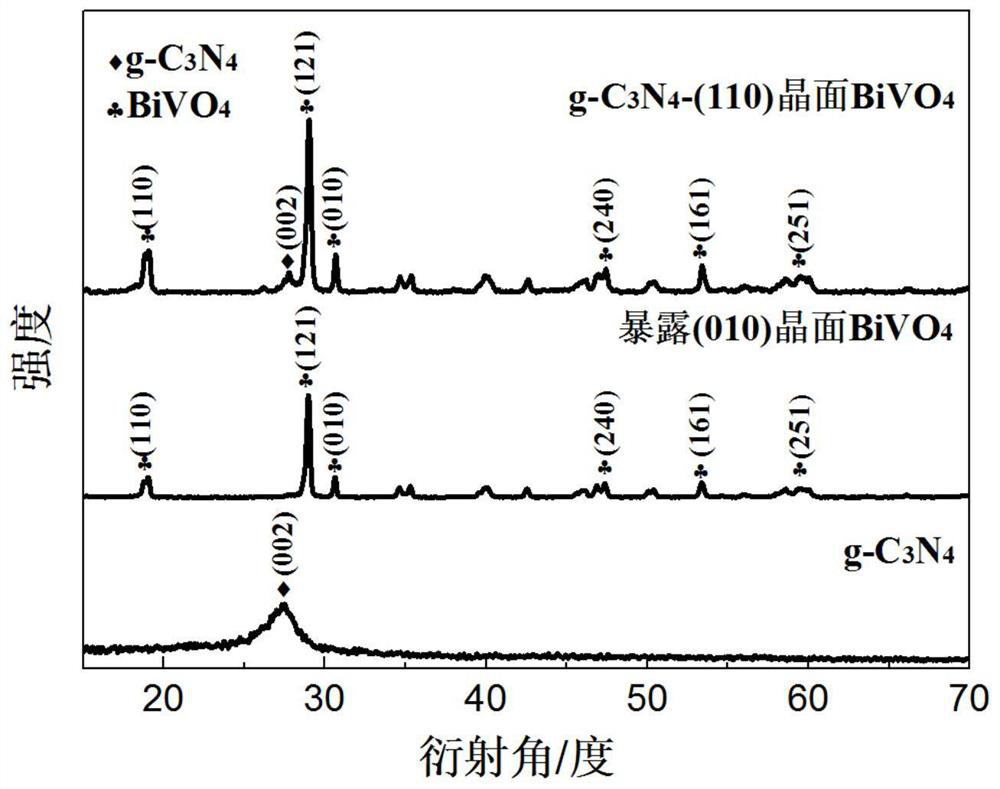

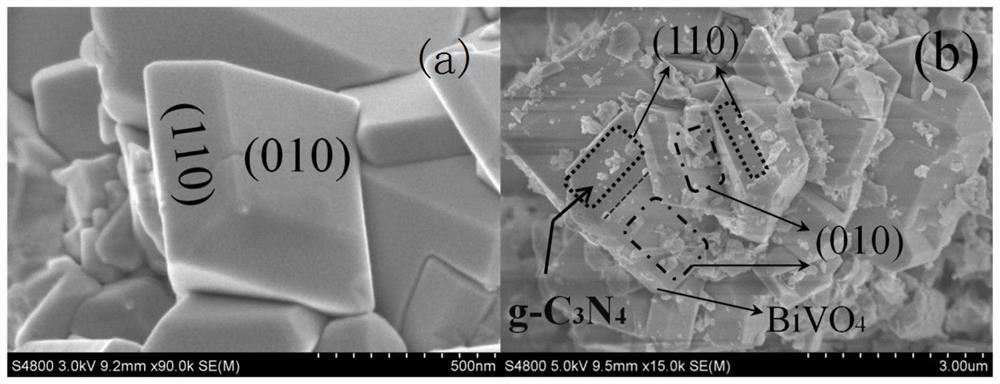

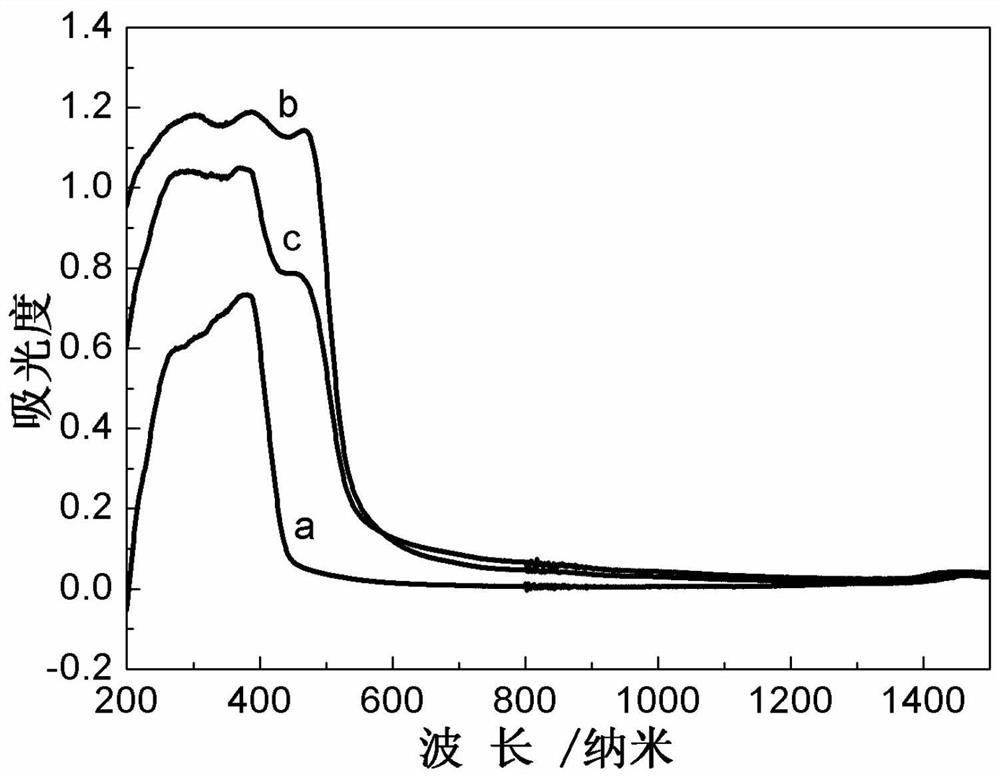

[0029] g-C of the present invention 3 N 4 -(110) crystal plane BiVO 4 The preparation method of Z-type heterojunction photocatalyst comprises the following steps:

[0030] Step 1, the Bi(NO 3 ) 3 ·5H 2 O dissolved in HNO 3 solution, after stirring for a certain period of time, NH 4 VO 3 , stirred for 120 minutes to form a precursor solution, and the precursor solution was hydrothermally reacted at 65-75°C for 14-16 hours to prepare BiVO 4 precipitation, the precipitation was washed with water and alcohol and then dried for later use; Bi(NO 3 ) 3 ·5H 2 O. NH 4 VO 3 The mass ratio is 3.54:1;

[0031] Step 2, CO(NH 2 ) 2 Raise the temperature to 540-560°C at a heating rate of 4.5-5.5°C / min, keep the heat for calcination for 2.8-3.2 hours, then lower the temperature to 350°C to obtain pure phase g-C 3 N 4 Powder, the pure phase g-C 3 N 4 Dissolve the powder in deionized water, add 10mL of a certain concentration of H 2 SO 4 The solution was stirred ultrasonica...

Embodiment 1

[0042] Step 1, 6mmol Bi(NO 3 ) 3 ·5H 2 O dissolved in 35 mL of HNO with a concentration of 1 mol / L 3 solution, after stirring for 30min, add 6mmol NH 4 VO 3 , stirred for 120min to form a precursor solution, and the precursor solution was hydrothermally reacted at 65°C for 14h to prepare BiVO 4 Precipitation, washing the precipitate with alcohol and water for later use;

[0043] Step 2, CO(NH 2 ) 2 Raise the temperature to 540°C at a heating rate of 4.5°C / min, and then cool down to 350°C to obtain a pure phase g-C 3 N 4 Powder, the pure phase g-C 3 N 4 Dissolve the powder in deionized water, add 10 mL of H with a concentration of 0.5 mol / L 2 SO 4 The modified g-C was obtained by ultrasonic stirring for 3 h 3 N 4 Powder, washed with alcohol and water for later use;

[0044] Step 3, 0.05g modified g-C 3 N 4 Dissolve in 40mL deionized water, stir, and sonicate for 3.0 h until uniform, to obtain negatively charged g-C 3 N 4 solution and subjected to 25min ultrav...

Embodiment 2

[0048] Step 1, 6mmol Bi(NO 3 ) 3 ·5H 2 O dissolved in 35 mL of HNO with a concentration of 1 mol / L 3 solution, after stirring for 30min, add 6mmol NH 4 VO 3 , stirred for 120min to form a precursor solution, and the precursor solution was hydrothermally reacted at 70°C for 15h to prepare BiVO 4 Precipitation, washing the precipitate with alcohol and water for later use;

[0049] Step 2, CO(NH 2 ) 2 Raise the temperature to 550°C at a rate of 5°C / min, then cool down to 350°C to obtain a pure phase g-C 3 N 4 Powder, the pure phase g-C 3 N 4 Dissolve the powder in deionized water, add 10mL of 1mol / L H 2 SO 4 The modified g-C was obtained by ultrasonic stirring for 3.5h 3 N 4 Powder, washed with alcohol and water for later use;

[0050] Step 3, 0.1g modified g-C 3 N 4 Dissolve in 40mL deionized water, stir, and sonicate for 3.0h until uniform to obtain negatively charged g-C 3 N 4 solution and subjected to 35min ultraviolet light to obtain negatively charged g-C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com