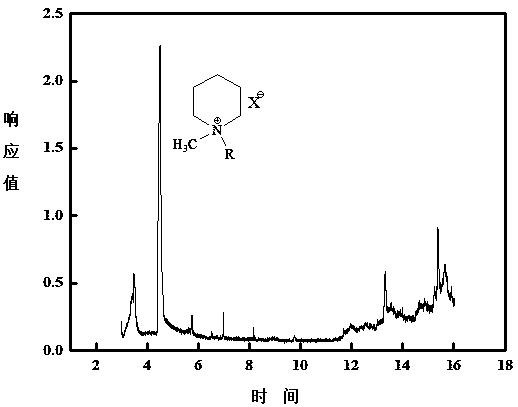

A kind of piperidine type ionic liquid and its preparation method and application

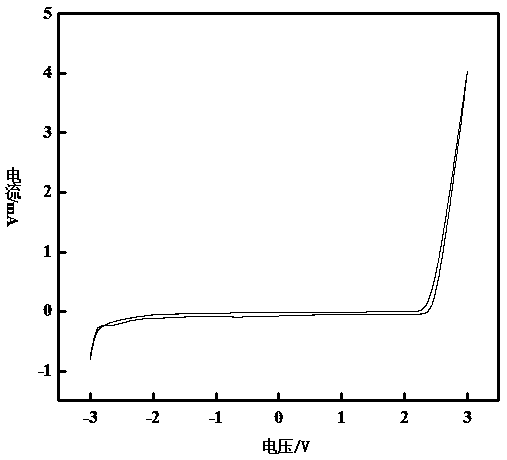

An ionic liquid and piperidine-type technology, which is applied in the field of piperidine-type ionic liquid and its preparation, can solve the problems of restricting industrial production, large impedance, harsh test conditions, etc., and achieve good and stable electrochemical performance, battery impedance reduction, impedance reduce the apparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

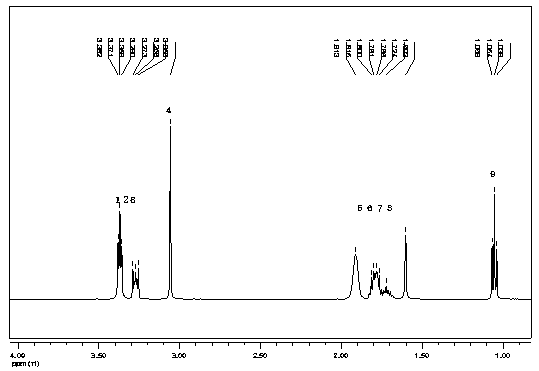

[0045] Step 1: Add 1.1 mol of bromopropane to 200 mL of ethyl acetate, stir at 20°C, slowly add 1 mol of N-methylpiperidine dropwise at a rate of 5.5 g / min, stir for 12 hours, filter with suction, and separate the obtained solid phase for use Rinse with acetone, and after rinsing, vacuumize and rotate at 80°C for 6.5h to obtain the intermediate product; the conditions for acetone rinsing are: rinse 3 times, and the amount of acetone each time is 0.8mL / g based on the mass of the solid phase. The wash time is 0.55s / mL based on the amount of acetone used.

[0046] Step 2: Weigh 100 g of the intermediate product and add it to 200 mL of water to dissolve, then add 130 g of lithium trifluoromethanesulfonyl imide, stir for 1 hour, extract with 400 mL of organic solvent, and wash the organic phase with water for 5 times after liquid separation until it is free of halogen ions , after cleaning, the final organic phase obtained was vacuumized at 80°C for 6h and dried to obtain the produ...

Embodiment 2

[0053] Step 1: Add 1.1 mol of bromopropane to 200 mL of ethyl acetate, stir at 20°C, slowly add 1 mol of N-methylpiperidine dropwise at a rate of 5.5 g / min, stir for 8 hours, and use ultrasonic waves with a frequency of 45KHZ during the reaction , suction filtration, the separated solid phase was rinsed with acetone, and after the rinse, vacuumized and rotated at 80°C for 6.5h to obtain the intermediate product; the conditions for the acetone rinse were: rinse 3 times, and the amount of acetone each time was based on the amount of the solid phase The mass of the solution is 0.8mL / g, and the washing time is 0.55s / mL based on the amount of acetone used.

[0054] Step 2: Weigh 100 g of the intermediate product and add it to 200 mL of water to dissolve, then add 130 g of lithium trifluoromethanesulfonimide, stir for 1 h, use microwave intensification during the stirring reaction, extract with 400 mL of organic solvent, and separate the organic phase Wash with water for 5 times unt...

Embodiment 3

[0060] Step 1: Add 0.22mol bromopropane to 200mL ethyl acetate, stir at 20°C, slowly add 0.218mol N-methylpiperidine dropwise at a rate of 1.1g / min, stir for 8 hours, and use ultrasonic waves with a frequency of 30KHz during the reaction , suction filtration, the separated solid phase was rinsed with acetone, and after the rinse, vacuumized and rotated at 80°C for 5 hours to obtain the intermediate product; the conditions for the acetone rinse were: rinse once, and the amount of acetone each time was based on the solid phase The mass is 0.3mL / g, and each washing time is 0.1s / mL based on the amount of acetone.

[0061] Step 2: Weigh 20 g of the intermediate product and add it to 200 mL of water to dissolve, then add 22 g of lithium trifluoromethanesulfonyl imide, stir for 1 h, use microwave intensification during the stirring reaction, extract with 400 mL of organic solvent, and separate the organic phase Wash with water for 5 times until there is no halogen ion. After washing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com