Fabricated graphene heating wallboard

A graphene, assembled technology, applied to walls, electric heating devices, ohmic resistance heating, etc., can solve the problems of low hardness and easy damage, large space occupation, low energy efficiency, etc. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

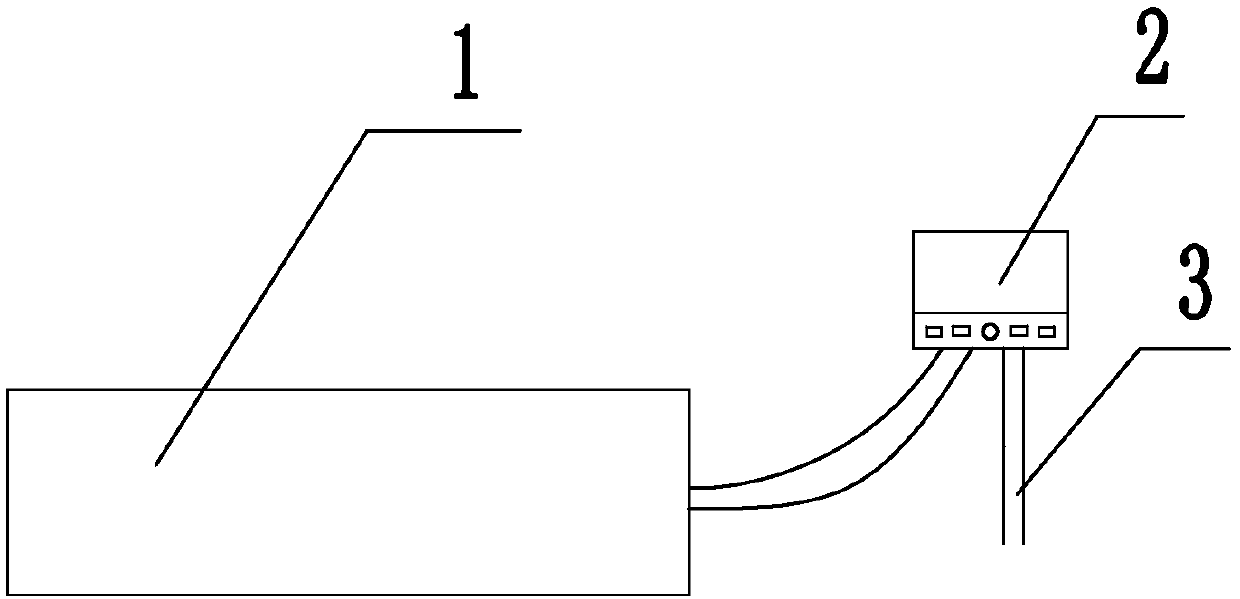

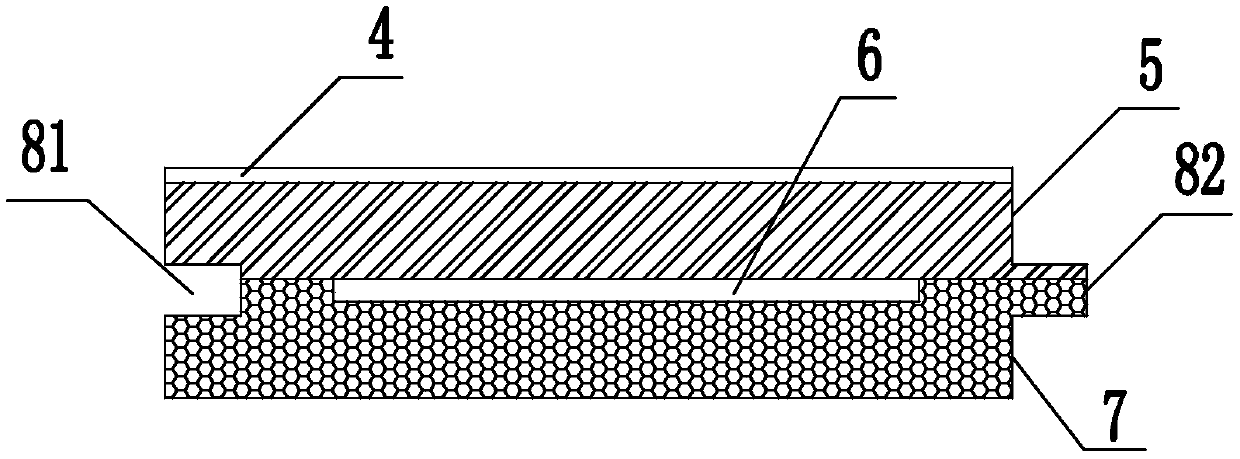

[0022] refer to Figure 1 to Figure 2 , an assembled graphene heating wallboard, comprising a heating wallboard 1, a temperature control unit 2, and a cable unit 3, wherein the heating wallboard 1 is sequentially arranged from top to bottom with a polytetrafluoroethylene film layer 4, bamboo wood The fiber layer 5, the graphene heating layer 6, and the nanofiber layer 7 are composed of a groove, the graphene heating layer 6 is placed in the groove, and the graphene heating layer 6 passes through the wire It is electrically connected to the temperature control unit 2, the temperature control unit 2 is connected to the power supply through the cable unit 3, and the opposite two edges of the four edges of the heating wallboard 1 are respectively a concave tenon 81 and a The tenon opening 82, the tenon opening 81 and the tenon opening 82 are inserted into the tenon opening and the tenon opening of another graphene heating wallboard respectively.

[0023] The preparation method of...

Embodiment 2

[0027] A kind of assembled type graphene heating wallboard, its structure is consistent with embodiment one, and the preparation method of described graphene heating layer is as follows:

[0028] (1) Add 2 parts by weight of graphene, 14 parts by weight of carbon black, 1.5 parts by weight of silicon dioxide, and 3 parts of silane coupling agent into 45 parts of isopropanol, carry out ultrasonic dispersion for 4.5 hours, and then add 35 parts by weight of organic Silicone resin, 0.4 parts by weight tris(2-chloroethyl) phosphate, 1.2 parts by weight asbestos powder, sheared at high speed with a high-speed shear for 2.5 hours; then added 0.8 parts by weight of polyurethane associative thickener, mixed and stirred for 25 minutes , to obtain graphene heating slurry crude liquid;

[0029] (2) add 8 weight parts two 2,4-dichlorobenzoyl peroxides, 0.5 weight part dibutyltin diacetate in the crude liquid of graphene heating slurry, obtain the graphene heating slurry after stirring, im...

Embodiment 3

[0031] A kind of assembled type graphene heating wallboard, its structure is consistent with embodiment one, and the preparation method of described graphene heating layer is as follows:

[0032] (1) Add 5 parts by weight of graphene, 8 parts by weight of carbon black, 3 parts by weight of silicon dioxide, and 5 parts of silane coupling agent into 60 parts of isopropanol, carry out ultrasonic dispersion for 5 hours, and then add 50 parts by weight of organic silicon Resin, 0.6 parts by weight of tris (2-chloroethyl) phosphate, and 2 parts by weight of asbestos powder were sheared at high speed with a high-speed shear for 3 hours; then 1.5 parts by weight of polyurethane associative thickener was added, and mixed and stirred for 30 minutes to obtain Graphene heating slurry crude liquid;

[0033] (2) add 10 parts by weight of two 2,4-dichlorobenzoyl peroxides, 0.6 parts by weight of dibutyltin diacetate in the crude liquid of the graphene heating slurry, stir to obtain the graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com