Process for denitrification and electricity generation by using single-chamber anaerobic ammonium oxidation sludge-microbial fuel cell device

An anaerobic ammonia oxidation and fuel cell technology, which is applied in the field of environmental engineering to achieve sustainable development, ensure high efficiency, and have wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

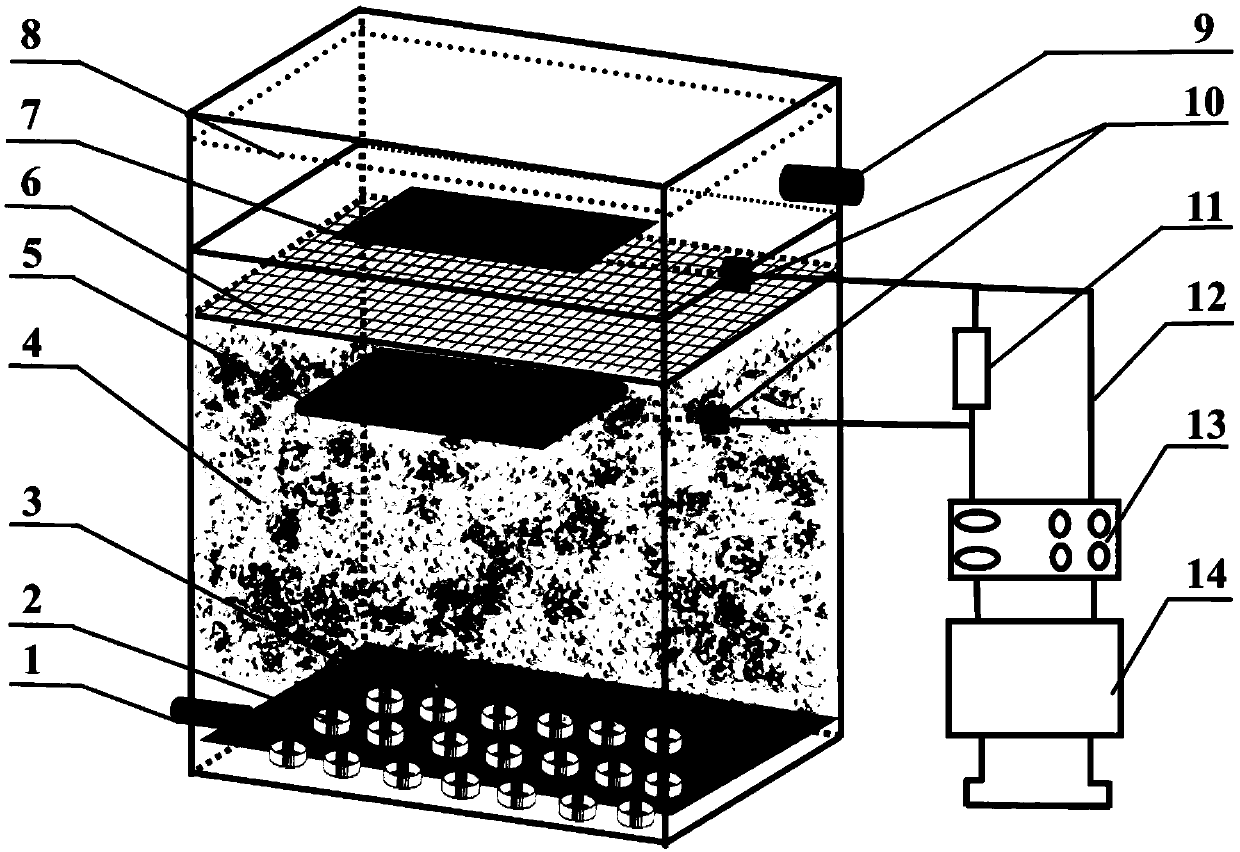

[0020] A single-chamber anammox sludge-microbial fuel cell device with a total nitrogen load of 0.23-1.74Kg N / m 3 d. The lower anode area is filled with anaerobic ammonium oxidation sludge loaded on activated carbon particles, separated from the upper cathode area by a stainless steel mesh, and the vertical distance between the stainless steel mesh and the bottom of the device is 9cm. The anode carbon felt is placed in the sludge, and the cathode catalytic electrode is fixed by a plate frame and placed parallel to the anode carbon felt, with a vertical distance of 1.5cm, and the length and width are the same as the anode carbon felt.

[0021] Cathodic catalytic electrode preparation method: (1) Burn the carbon fiber cloth at a high temperature of 550°C for 3 hours in the nitrogen flow of a vacuum tube furnace, soak it in concentrated sulfuric acid:concentrated hydrochloric acid = 3:1 for 18 hours, activate the surface of the carbon cloth, and separate them in ethanol, Ultraso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com