Method for preparing mycotoxin adsorbent by using semicoke

A mycotoxin adsorption and semi-coke technology, applied in the field of animal feed and waste resource reuse, can solve the problem of lack of ecological benefits, and achieve the effect of inhibiting the growth of mold, improving the removal effect and prolonging the shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

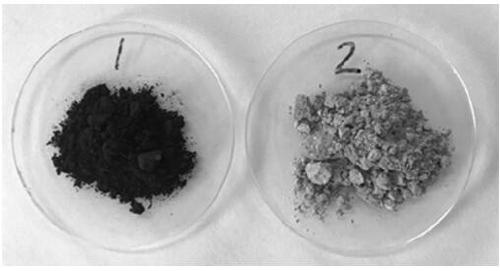

Image

Examples

Embodiment 1

[0017] The semi-coke raw material was crushed and calcined at 350°C for 4 hours; 150g was weighed and dispersed in 500ml of water to prepare a dispersion with a solid-to-liquid ratio of 30%, and then sulfuric acid (content 98%) with 10% mass of semi-coke was added and reacted for 4 hours ; The product is washed with water, washed with alcohol, and dried to obtain purified semi-coke;

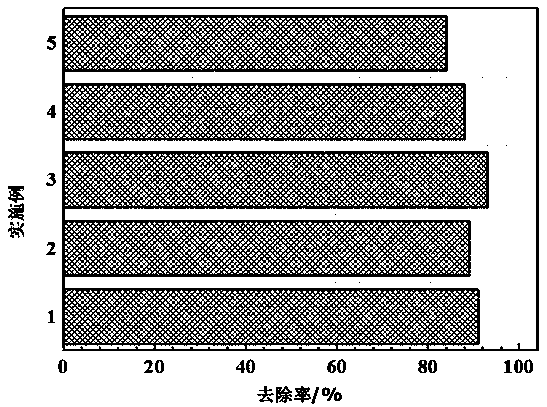

[0018] Weigh 100g of purified semi-coke, 3g of sodium acetate, and dissolve 120g of distilled water with 2.5g of octadecyldimethylbenzyl ammonium chloride, mix evenly and add to a planetary ball mill to grind for 60min (material: ball: water mass Ratio=1:10:1.2), unloading, drying, and grinding to obtain mycotoxin adsorbent. In vitro adsorption performance of this product on zearalenone see figure 2 .

Embodiment 2

[0020] The raw semi-coke was crushed and calcined at 500°C for 4 hours. Weigh 150g and disperse in 250ml water to prepare a dispersion with a solid-to-liquid ratio of 60%; add sulfuric acid (98% content) with 5% mass of semi-coke, react for 4 hours, and wash the product with water, alcohol, and dry to obtain purified semi-coke;

[0021] Weigh 100g of purified semi-coke, 5g of calcium propionate, and dissolve 100g of distilled water with 3g of octadecyltrimethylammonium chloride, mix evenly and add to a planetary ball mill to grind for 120min (material: ball: water mass ratio = 1:6:1), unloading, drying, and grinding to obtain mycotoxin adsorbent. In vitro adsorption performance of this product on zearalenone see figure 2 .

Embodiment 3

[0023] The raw semi-coke was crushed and then calcined at 700°C for 2 hours; 150g was weighed and dispersed in 500ml water to prepare a dispersion with a solid-to-liquid ratio of 30%, and sulfuric acid (content 98%) with 5% semi-coke mass was added to react for 4 hours; the product After washing with water, washing with alcohol and drying, the purified semi-coke is obtained;

[0024] Weigh 100g of purified semi-coke, 7g of sodium diacetate, 4g of cetyltrimethylammonium bromide, and 80g of water, mix them evenly, and add them to a planetary ball mill to grind for 240min (mass ratio of material: ball: water = 1: 4:0.8), unloading, drying and crushing to obtain mycotoxin adsorbent. The in vitro adsorption performance of this product on zearalenone see figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com