Sand grinding modification method of lithium ion battery mineral negative electrode material

A lithium-ion battery and negative electrode material technology, applied in the field of electrochemical performance of lithium-ion batteries, can solve the problems of poor electronic conductivity, coarse particle size, and unsatisfactory electrochemical performance of zinc concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) The zinc concentrate-1# sample was taken from a concentrator, and the Zn content was measured to be 52.99% (mass ratio).

[0019] (2) Use QM-WX4 type planetary ball mill to grind the zinc concentrate with 400 rpm for 6 hours, then grind it for 8 hours with PHE0.5 type horizontal sand mill with 1500 rpm for 8 hours to obtain micronano zinc concentrate Mine-1# sample, its BET specific surface is 28.41m 2 / g, scanning electron microscope (SEM) photo (see figure 1 ) shows that most of its particle size is less than 100nm, and there are aggregates with a particle size of about 400nm.

[0020] (3) Grinding and mixing the micronano zinc concentrate-1# sample prepared in (2) with acetylene black and polyvinylidene fluoride (PVDF) binder in a 7:2:1 mass ratio in an agate mortar, Add dropwise analytically pure N-methylpyrrolidone (NMP) 5 times the mass of the mixture, grind it into a uniform slurry, coat it on the surface of the copper foil and dry it in an oven at 80°C for...

Embodiment 2

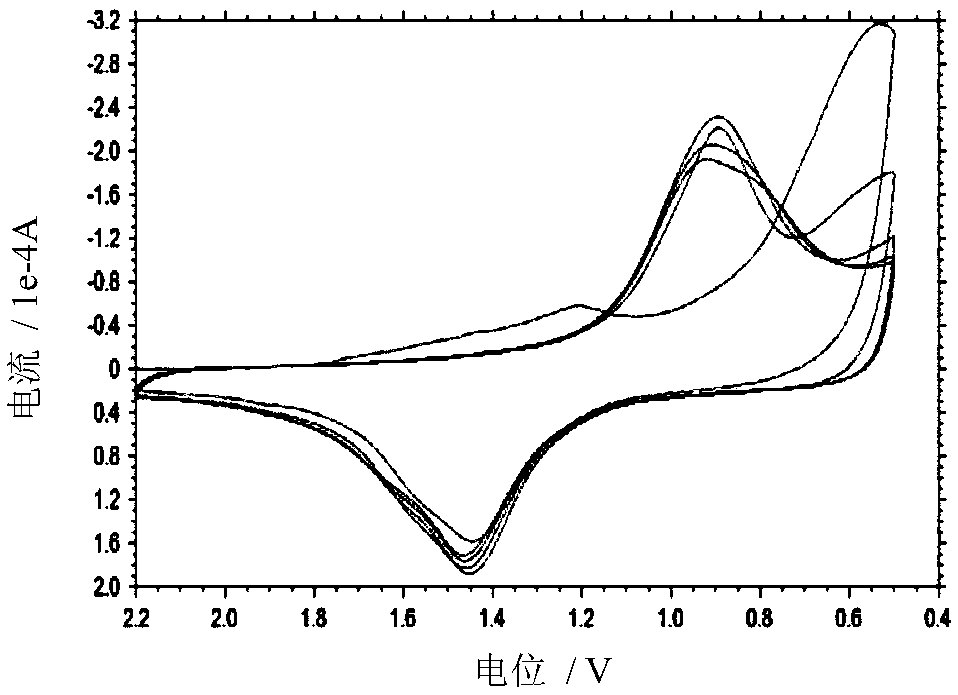

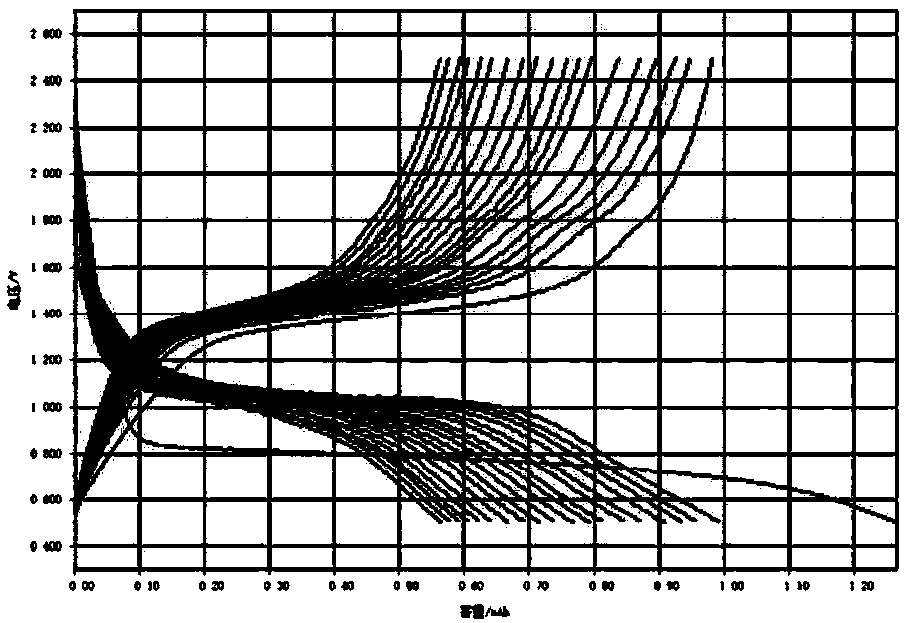

[0023] Take the zinc concentrate-2# sample from a certain ore dressing plant, send and record its Zn content to be 45.12% (mass ratio), adopt the (2) method of embodiment 1 to obtain the micronano zinc concentrate-2# sample, its BET The specific surface area is 27.85m 2 / g, scanning electron microscope (SEM) photo (see Figure 4 ) shows that most of the particles have a particle size of less than 100nm, there are aggregates with a particle size of about 400nm, and there are also individual larger agglomerated particles. All the other steps are exactly the same as (3), (4) of embodiment 1, cyclic voltammetry and charge-discharge performance (see attached Figure 5 ) test results show that the micro-nano zinc concentrate-2# sample also has good electrochemical reaction reversibility, its first discharge specific capacity is 736.6mAh / g, and the specific capacity of the 20th cycle is 523.1mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com