Preparation method, product and application of molybdenum oxide nano material

A nanomaterial, molybdenum oxide technology, applied in the direction of molybdenum oxide/molybdenum hydroxide, heavy metal active ingredients, drug combinations, etc., can solve the problems of limiting the wide application of photothermal therapy, poor patient adaptability, etc., and achieve a good possibility of clinical transformation. , controllable conditions, improve the effect of tumor treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Disperse 80 mg of molybdenum acetylacetonate, 0.2 g of hexadecylamine and 2 ml of oleic acid in 8 ml of octadecene, heat and stir at 100° C. for 10 min to generate a molybdenum oxide nano-intermediate.

[0049] (2) Transfer the mixture in step (1) to a 15ml high-pressure hydrothermal kettle, heat it to 200°C, and after 12 hours of reaction, take out the hydrothermal kettle and cool it to room temperature, collect the precipitate by ethanol centrifugation, and centrifuge to obtain a sea urchin-shaped hollow Molybdenum oxide nanomaterials (MoO 3-x NUs), and washed three times with absolute ethanol and dispersed in chloroform.

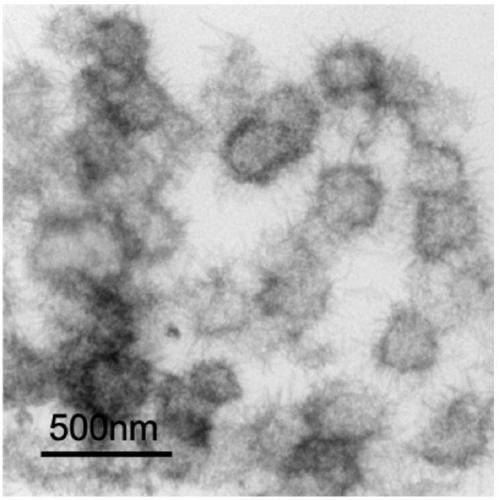

[0050] The morphology of sea urchin-like hollow molybdenum oxide nanomaterials was characterized by TEM, and the results are shown in the attached figure 1 As shown, the particle size is in the range of 300-500nm.

Embodiment 2

[0052] (1) Disperse 100 mg of molybdenum acetylacetonate, 0.2 g of hexadecylamine and 2 ml of oleic acid in 8 ml of octadecene, heat and stir at 120° C. for 10 min to generate a molybdenum oxide nano-intermediate.

[0053] (2) Transfer the mixture in step (1) to a 15ml high-pressure hydrothermal kettle, heat it to 180°C, and after 12 hours of reaction, take out the hydrothermal kettle and cool it to room temperature, collect the precipitate by ethanol centrifugation, and centrifuge to obtain a sea urchin-shaped hollow Molybdenum oxide nanomaterials (MoO 3-x NUs), and washed three times with absolute ethanol and then dispersed in chloroform, the obtained sea urchin-like hollow molybdenum oxide nanomaterials had a size of 300-600 nm.

Embodiment 3

[0055] (1) Disperse 120 mg of molybdenum acetylacetonate, 0.2 g of hexadecylamine and 4 ml of oleic acid in 8 ml of octadecene, heat and stir at 100° C. for 20 minutes to generate a molybdenum oxide nano-intermediate.

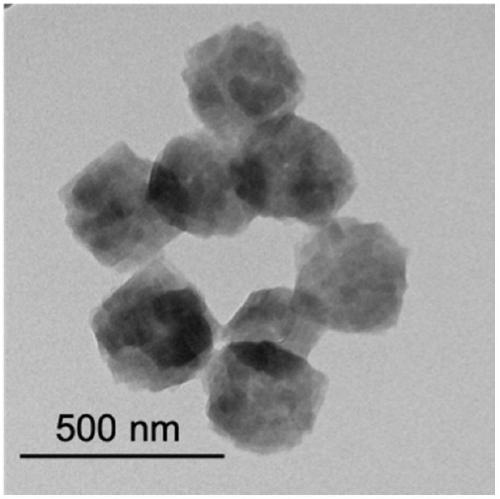

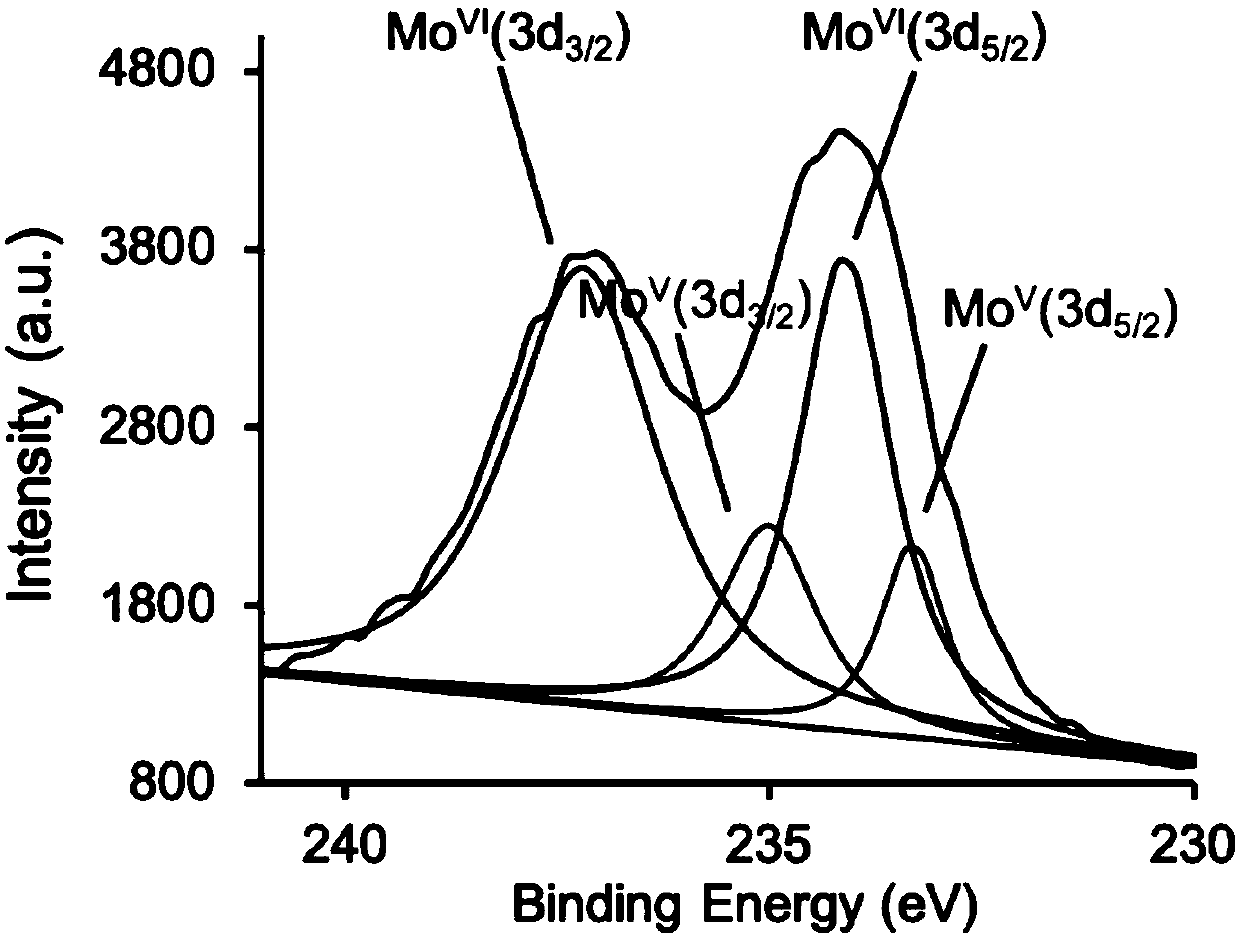

[0056] The intermediate product molybdenum oxide nano-intermediate was characterized by TEM and XPS respectively. TEM characterization as figure 2 As stated above, it is proved that the intermediate product is a nano-scale particle with a particle diameter of 200-400nm. XPS characterization as image 3 As shown, it proves that part of the hexavalent molybdenum has been reduced to pentavalent molybdenum during the heating process.

[0057] (2) Transfer the mixture in step (1) to a 15ml high-pressure hydrothermal kettle, heat it to 160°C, and after 12 hours of reaction, take out the hydrothermal kettle and cool it to room temperature, collect the precipitate by ethanol centrifugation, and centrifuge to obtain a sea urchin-shaped hollow Molybdenum oxide nanoma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com